Embarking on the journey of 3D printing with specialty filaments opens up a world of creative possibilities, from intricate metal-infused designs to the natural feel of wood-filled creations. However, unlocking the full potential of these advanced materials often hinges on a seemingly small, yet critically important component: the nozzle. Understanding how different filament compositions interact with nozzle materials, diameters, and geometries is paramount to achieving successful, high-quality prints and avoiding common frustrations.

This guide is designed to demystify the selection process, providing clear insights into the unique demands of specialty filaments and the specific nozzle characteristics that best meet those needs. We will explore the nuances of various filament types, the wear resistance of different nozzle materials, and how diameter and geometry play a crucial role in extrusion, clogging prevention, and overall print performance.

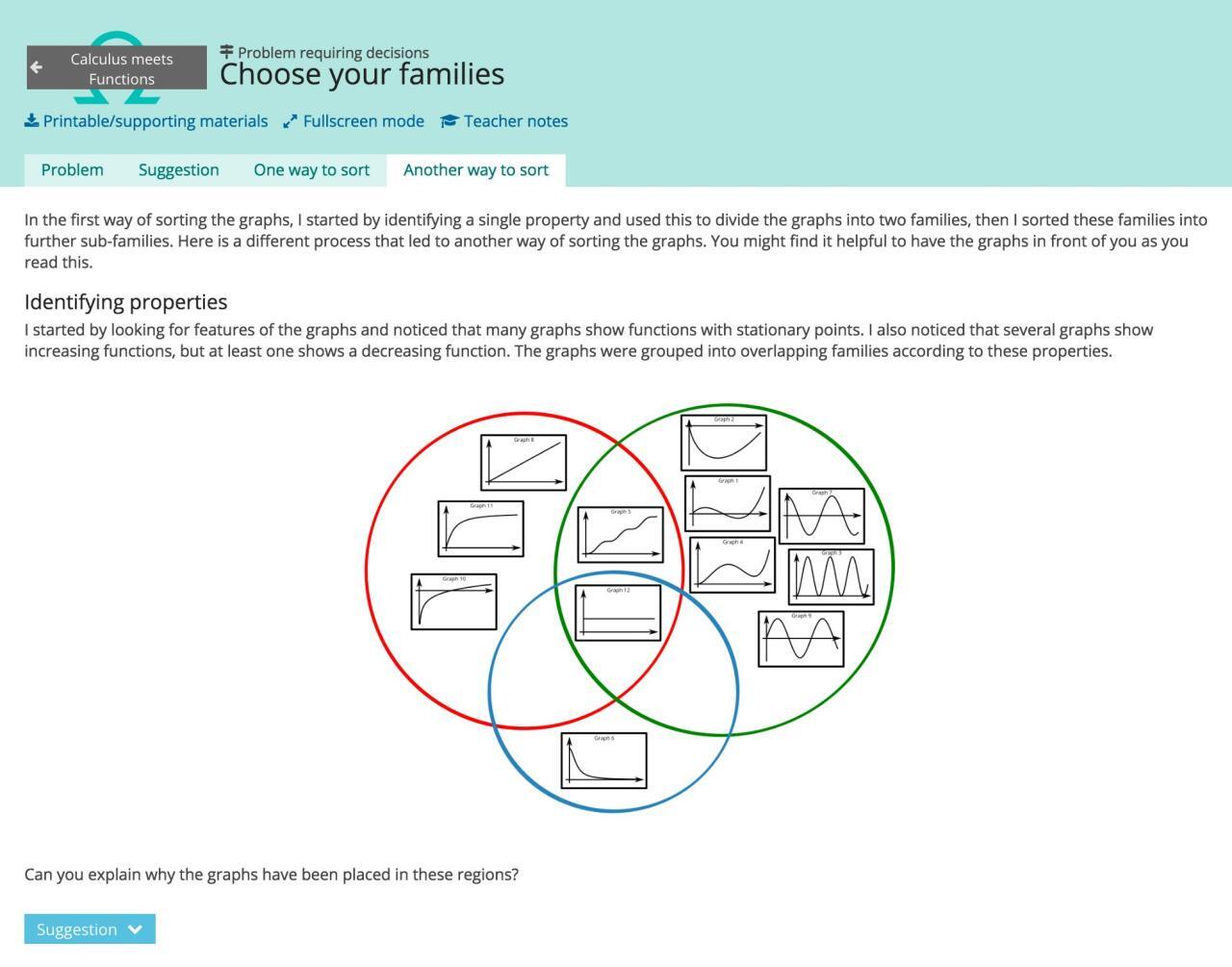

Understanding Specialty Filaments and Their Nozzle Needs

The world of 3D printing has expanded dramatically beyond basic PLA and ABS, with a growing array of specialty filaments offering enhanced properties for diverse applications. These advanced materials, however, often present unique challenges that standard brass nozzles are ill-equipped to handle. Understanding the specific characteristics of these filaments is the crucial first step in selecting the appropriate nozzle to ensure successful, high-quality prints and to prevent premature wear on your equipment.Each category of specialty filament possesses distinct material properties that directly influence the demands placed upon a 3D printer’s nozzle.

These properties can range from increased hardness and abrasiveness due to particulate additives to enhanced flexibility or higher printing temperatures. Consequently, the choice of nozzle material and design becomes paramount for achieving optimal print outcomes and extending the lifespan of both the nozzle and the printer itself.

Common Categories of Specialty Filaments and Their Nozzle Demands

Specialty filaments are broadly categorized based on their composition and the unique properties they impart to 3D printed objects. Each category requires specific considerations for nozzle selection due to the physical and chemical interactions that occur during the extrusion process.

- Carbon Fiber Reinforced Filaments: These filaments incorporate chopped carbon fibers into a base polymer (like PLA, PETG, or Nylon) to significantly increase stiffness, strength, and heat resistance while reducing weight. The carbon fibers, while beneficial for print properties, are highly abrasive.

- Wood-Filled Filaments: Composed of a base polymer blended with finely ground wood particles, these filaments offer a wood-like aesthetic and texture. The wood particles, especially if larger or less uniformly processed, can be abrasive and may clog smaller nozzle openings.

- Metal-Filled Filaments: These filaments contain fine metal powders (such as bronze, copper, or stainless steel) mixed with a polymer binder. They allow for prints with a metallic sheen and can be polished to a high finish. The metal particles are significantly abrasive and can wear down standard nozzle materials rapidly.

- Flexible Filaments (TPU, TPE): These materials are designed for their elasticity and resilience, suitable for applications requiring shock absorption or flexibility. While not inherently abrasive, their low viscosity at printing temperatures can lead to “stringing” and oozing, which may require specific nozzle geometries or retraction settings. The primary challenge is managing the filament’s tendency to deform under pressure, necessitating careful extruder calibration and sometimes specialized hotend designs.

- Abrasive Filaments (e.g., Glow-in-the-Dark, Ceramic-Filled): Beyond carbon fiber and metal-filled, other filaments incorporate abrasive additives like phosphorescent particles or ceramic powders to achieve special visual effects or material properties. These additives are often hard and crystalline, leading to significant wear on nozzle tips.

Material Properties Influencing Nozzle Selection

The inherent properties of specialty filaments dictate the type of nozzle that will perform best. Factors such as hardness, melting point, viscosity, and particle size are critical.

- Hardness and Abrasiveness: The presence of hard particles like carbon fiber, metal powders, or ceramic fillers is the most significant factor driving nozzle wear. These materials are harder than standard brass, leading to accelerated erosion of the nozzle’s inner diameter and tip.

- Melting Point and Viscosity: Some specialty filaments require higher printing temperatures than common materials. This can place additional thermal stress on the nozzle and hotend. Furthermore, materials with very low viscosity at printing temperatures can be prone to oozing, while those with high viscosity may require higher extrusion pressures, potentially leading to nozzle wear if the material is also abrasive.

- Particle Size and Distribution: The size and consistency of particulate additives within filaments can affect their flow through the nozzle. Larger or irregularly shaped particles are more likely to cause blockages and increase wear.

Primary Challenges in Printing Specialty Filaments

Printing with specialty filaments often introduces unique challenges that directly relate to nozzle performance and selection. Addressing these challenges is key to achieving successful prints.

- Nozzle Wear and Erosion: This is the most common challenge with abrasive filaments. Standard brass nozzles can be worn down significantly within a few hundred printing hours, leading to a wider extrusion width, poor print quality, and potential nozzle blockages.

- Clogging: Larger particles or inconsistent filament extrusion can lead to nozzle clogs, particularly with wood-filled or some metal-filled filaments.

- Poor Print Quality: Accelerated nozzle wear can result in a loss of detail, inconsistent extrusion lines, and overall degraded print quality.

- Stringing and Oozing: Flexible filaments, in particular, can be prone to stringing due to their inherent elasticity and lower viscosity at extrusion temperatures.

- Thermal Degradation: Some specialty filaments may degrade if exposed to excessively high temperatures for prolonged periods, which can be influenced by nozzle material and hotend design.

Impact of Filament Abrasiveness on Standard Nozzle Materials

Standard 3D printer nozzles are typically made of brass. Brass is a relatively soft alloy, making it easy to machine and cost-effective. However, its softness makes it highly susceptible to abrasion from harder materials.

The abrasive nature of particles within specialty filaments directly erodes the internal surfaces of a brass nozzle, altering its internal diameter and tip geometry. This wear is progressive and significantly reduces print quality over time.

When printing with filaments containing hard particles such as carbon fiber, metal powders, or glass fibers, the constant friction between the filament and the nozzle material causes the brass to wear away. This wear manifests as:

- An increase in the nozzle’s internal diameter, leading to over-extrusion and loss of fine detail.

- A rounded or deformed nozzle tip, affecting the smoothness of the first layer and the overall finish of the print.

- Reduced print accuracy and dimensional stability.

- An increased likelihood of nozzle clogs as the worn surfaces can trap filament debris.

The rate of wear is directly proportional to the abrasiveness of the filament and the duration of printing. For instance, printing with carbon fiber reinforced Nylon can wear out a brass nozzle in a matter of weeks or even days of continuous use, whereas printing with standard PLA might last for months or years. This necessitates the use of harder, more wear-resistant nozzle materials for specialty filaments.

Key Nozzle Material Considerations for Specialty Filaments

Selecting the appropriate nozzle material is paramount when venturing beyond standard PLA and ABS filaments. Specialty filaments, often incorporating abrasive additives like carbon fiber, metal powders, or glow-in-the-dark particles, can rapidly wear down conventional brass nozzles. Understanding the properties of different nozzle materials will help you make an informed decision to ensure print quality and nozzle longevity.This section will delve into the wear resistance of common nozzle materials, the specific benefits and drawbacks of hardened steel, and the advantages offered by ruby and tungsten carbide for demanding applications.

We will also provide guidance on matching nozzle material to filament composition.

Nozzle Material Wear Resistance Comparison

The longevity of a nozzle is directly correlated with its hardness and resistance to abrasion. While brass is a common and affordable material, it is significantly softer than other options and susceptible to wear from abrasive filaments.

| Material | Hardness (Mohs Scale) | Wear Resistance | Typical Use Cases |

|---|---|---|---|

| Brass | 3-4 | Low | Standard filaments (PLA, ABS, PETG) |

| Hardened Steel | 5-6 | Good | Carbon fiber, wood-filled, metal-filled filaments |

| Tungsten Carbide | 9-9.5 | Excellent | Extremely abrasive filaments, high-temperature printing |

| Ruby | 9 | Excellent | Extremely abrasive filaments, high-temperature printing, minimal friction |

Hardened Steel Nozzles for Abrasive Filaments

Hardened steel nozzles represent a significant upgrade over brass for printing with filaments that contain abrasive fillers. These filaments, such as those infused with carbon fiber or metal particles, act like sandpaper against the nozzle tip, leading to rapid wear. A brass nozzle can show noticeable wear within a few hundred grams of printing such abrasive material, resulting in larger extrusion diameters and poorer print quality.

Hardened steel, being considerably harder, resists this abrasive action much more effectively, extending the nozzle’s lifespan significantly.The benefits of using hardened steel nozzles include:

- Extended Lifespan: Significantly longer durability compared to brass when printing abrasive filaments.

- Consistent Extrusion: Maintains a more consistent orifice diameter, leading to better dimensional accuracy and print quality over time.

- Cost-Effectiveness for Abrasives: While more expensive upfront than brass, they are more cost-effective in the long run for users who frequently print with abrasive materials due to their longevity.

However, there are also drawbacks to consider:

- Thermal Conductivity: Hardened steel generally has lower thermal conductivity than brass. This can lead to slightly less efficient heat transfer to the filament, potentially requiring slightly higher printing temperatures to achieve optimal flow.

- Corrosion: Some hardened steel nozzles can be prone to rust if not properly maintained, especially in humid environments.

- Machining Challenges: The hardness of the material makes them more difficult to machine, which can sometimes translate to higher manufacturing costs.

Ruby and Tungsten Carbide Nozzles for Extreme Applications

For filaments that push the boundaries of abrasiveness or require exceptionally high printing temperatures, ruby and tungsten carbide nozzles offer superior performance. These materials are among the hardest known substances, providing unparalleled resistance to wear and chemical degradation.Ruby nozzles, often featuring a copper or brass body with a synthetic ruby tip, excel due to the extreme hardness of ruby. This makes them exceptionally resistant to abrasion from even the most aggressive filament fillers.

The smooth surface of the ruby tip also contributes to reduced friction, potentially leading to more consistent filament feeding and extrusion. They are particularly well-suited for printing with:

- Extremely abrasive composite filaments (e.g., high-fiber content carbon fiber, ceramic-filled).

- Filaments that require very high printing temperatures, as ruby maintains its hardness and integrity at elevated temperatures.

Tungsten carbide nozzles are another excellent choice for extreme conditions. Tungsten carbide is renowned for its exceptional hardness and toughness, making it highly resistant to wear and deformation. Like ruby nozzles, they are ideal for:

- Filaments with aggressive abrasive properties, such as those containing metal powders or very fine abrasive particles.

- Applications demanding maximum nozzle lifespan and consistent performance under strenuous printing conditions.

- High-temperature printing where other materials might soften or degrade.

The advantages of these advanced materials include:

- Unmatched Durability: Significantly outlast hardened steel when dealing with the most abrasive filaments.

- High-Temperature Stability: Maintain their structural integrity and hardness at temperatures that would soften or deform other nozzle materials.

- Corrosion Resistance: Generally offer excellent resistance to corrosion and chemical attack.

The primary drawback of ruby and tungsten carbide nozzles is their cost, which is considerably higher than brass or even hardened steel. This makes them a specialized investment for users who frequently print with the most demanding specialty filaments.

Guidance on Nozzle Material Selection Based on Filament Composition

Choosing the right nozzle material is a direct function of the filament’s composition and the printing temperatures required. A careful assessment of your printing needs will lead to the most appropriate and cost-effective nozzle choice.Consider the following guidelines:

- Standard Filaments (PLA, ABS, PETG, TPU): For these common filaments, a standard brass nozzle is perfectly adequate and the most economical choice. Its good thermal conductivity ensures efficient heat transfer for reliable printing.

- Slightly Abrasive Filaments (Wood-filled, Metal-filled, some Carbon Fiber blends): When you start incorporating filaments with moderate amounts of fillers, such as wood particles, metal powders, or lower percentages of carbon fiber, a hardened steel nozzle is highly recommended. It offers a substantial improvement in wear resistance over brass, protecting your nozzle from premature degradation.

- Highly Abrasive Filaments (High-content Carbon Fiber, Glass Fiber, Ceramic-filled, Glow-in-the-Dark): For filaments that are known to be very abrasive, such as those with a high percentage of carbon fiber, glass fiber, ceramic particles, or the abrasive nature of glow-in-the-dark compounds, you should opt for a nozzle made from extremely hard materials. Tungsten carbide or ruby nozzles are the best choices here to ensure a long nozzle life and consistent print quality.

- Extremely High-Temperature Filaments (PEEK, PEI/ULTEM): If you are printing with advanced engineering thermoplastics that require very high nozzle temperatures (often exceeding 300°C), materials like hardened steel, tungsten carbide, or ruby are essential. These materials can withstand the extreme heat without softening or deforming, unlike brass.

In summary, brass is for everyday printing, hardened steel is for moderately abrasive and higher-temperature filaments, and tungsten carbide or ruby are the premium choices for the most challenging and abrasive specialty filaments, especially when combined with high-temperature requirements.

Nozzle Diameter and Flow Rate Optimization

Selecting the correct nozzle diameter is a critical step in successfully printing with specialty filaments. The nozzle’s orifice size directly influences how the filament is deposited, impacting print quality, speed, and the likelihood of experiencing print failures. This section will delve into the intricacies of nozzle diameter selection and flow rate adjustments to ensure optimal performance with a wide range of specialty materials.The interplay between nozzle diameter and print quality is multifaceted.

A smaller nozzle diameter allows for finer details and sharper corners, which is beneficial for intricate models. However, it also limits the volume of molten plastic that can be extruded per unit of time, leading to slower print speeds. Conversely, a larger nozzle diameter enables faster printing by extruding more material, but it sacrifices fine detail and can result in less precise features.

For specialty filaments, especially those with abrasive or particulate fillers, the nozzle diameter also plays a significant role in preventing clogs.

Nozzle Diameter and Print Quality for Specialty Filaments

The diameter of the nozzle directly dictates the width of the extruded line, commonly referred to as the “line width” or “extrusion width.” For specialty filaments, this has several implications for print quality. Smaller nozzle diameters, typically ranging from 0.2mm to 0.4mm, are ideal for achieving high levels of detail, sharp edges, and smooth surfaces. This is particularly important for functional prints where precise dimensions are crucial, or for aesthetic models where intricate features are desired.

However, printing with smaller nozzles requires careful calibration and can be significantly slower, as the printer has to deposit material in smaller increments.Larger nozzle diameters, such as 0.6mm, 0.8mm, or even 1.0mm and above, are advantageous for several reasons when working with specialty filaments. They allow for faster print times by depositing a greater volume of material per layer. This is especially beneficial for larger prints or when time is a constraint.

Furthermore, larger nozzles are generally more forgiving with filaments that might otherwise clog a smaller orifice, such as those containing significant amounts of filler material. The trade-off is a reduction in fine detail; curves may appear less smooth, and small features might be lost or blurred.

Nozzle Diameter and Clogging Potential with Filled Filaments

The presence of particulate fillers within specialty filaments, such as carbon fiber, wood particles, metal powders, or ceramic additives, poses a significant challenge to nozzle integrity and can lead to frequent clogs. These particles, even when finely ground, are often larger than the typical internal channels of standard brass nozzles. When filament containing these particles is extruded through a small nozzle orifice, these particles can become lodged, leading to a blockage.The relationship between nozzle diameter and clogging potential is inverse.

Smaller nozzle diameters have smaller internal channels and orifices, making them much more susceptible to clogging by filled filaments. Even a single larger particle can cause a jam. Larger nozzle diameters, on the other hand, provide a wider passage for the filament and its fillers to flow through, significantly reducing the risk of blockage. For filaments with even moderately sized particles, it is generally recommended to use a nozzle diameter that is at least 2-3 times the approximate size of the largest particles in the filament.

For instance, if a filament contains particles up to 0.3mm, a nozzle diameter of 0.6mm or larger would be a safer choice.

Tiered Approach for Nozzle Diameter Selection

To effectively manage the challenges posed by specialty filaments and to achieve desired print outcomes, a tiered approach to nozzle diameter selection based on filament particle size and desired print detail is highly recommended. This strategy helps balance the need for detail with the practicalities of printing with potentially abrasive or clog-prone materials.

- High Detail Prints with Minimal Fillers: For specialty filaments with very fine or no particulate fillers, and when the primary goal is achieving the highest possible level of detail and surface finish, a smaller nozzle diameter is appropriate.

- Recommended Diameters: 0.2mm, 0.25mm, 0.3mm, 0.4mm.

- Filament Types: High-resolution PLA, PETG, ABS, or specialty filaments with extremely fine additives that do not increase viscosity significantly.

- Considerations: Slower print speeds are essential. Ensure the printer’s motion system can handle the fine movements required for intricate details.

- Balanced Detail and Speed with Moderate Fillers: This tier is for specialty filaments that offer a good balance between material properties and printability, or those with moderate filler content that does not pose an extreme clogging risk. It aims for a good compromise between detail and print speed.

- Recommended Diameters: 0.4mm, 0.5mm, 0.6mm.

- Filament Types: Standard PLA, PETG, ABS, TPU, and specialty filaments with fine particulate fillers (e.g., some carbon fiber composites, wood-filled filaments with fine particles).

- Considerations: This is often the most versatile range. Adjust print speeds and temperatures based on filament manufacturer recommendations.

- Fast Prints and High Filler Content: For specialty filaments with significant particulate loading, abrasive materials, or when rapid printing of larger objects is the priority, larger nozzle diameters are necessary.

- Recommended Diameters: 0.6mm, 0.8mm, 1.0mm, and larger.

- Filament Types: Highly filled composites (e.g., dense carbon fiber, metal-filled, ceramic-filled), abrasive filaments, or when printing large, less detailed objects quickly.

- Considerations: Detail will be sacrificed. Ensure your extruder can handle the higher flow rates required. Heated nozzles and hardened steel nozzles are almost always required for these materials.

Flow Rate Adjustment Best Practices for Specialty Filaments

When changing nozzle diameters, it is crucial to adjust the flow rate (also known as extrusion multiplier or E-steps) to ensure consistent material deposition and prevent under-extrusion or over-extrusion. The relationship between nozzle diameter and flow rate is directly proportional: a larger nozzle requires a higher flow rate to achieve the same line width as a smaller nozzle, assuming all other factors remain constant.For specialty filaments, this adjustment is even more critical due to their often unique rheological properties and the presence of fillers.

Here are some best practices:

- Calibrate for Each Nozzle: Never assume that the flow rate calibrated for one nozzle diameter will be suitable for another. Even with the same filament, switching from a 0.4mm to a 0.6mm nozzle will necessitate an increase in flow rate.

- Understand the Proportionality: While not a perfect linear relationship due to fluid dynamics within the nozzle, a rough estimation can be made. If you increase the nozzle diameter by a factor of 1.5 (e.g., from 0.4mm to 0.6mm), you will likely need to increase the flow rate by a similar factor. For example, if your flow rate was 1.00 for a 0.4mm nozzle, it might need to be around 1.50 for a 0.6mm nozzle.

- Use Calibration Prints: The most reliable method is to print a single-wall cube or a calibration tower with the new nozzle diameter and the adjusted flow rate. Observe the print for signs of under-extrusion (gaps between lines, weak layer adhesion) or over-extrusion (blobs, rough surfaces, nozzle scraping the print).

- Consider Filament Properties: Specialty filaments, especially those with high filler content or significant viscosity changes with temperature, may require flow rate adjustments beyond simple geometric proportionality. Highly filled filaments often require higher flow rates to compensate for the reduced volume of polymer and increased resistance.

- Adjust in Small Increments: When fine-tuning the flow rate, make adjustments in small increments (e.g., 1-5%). Print a test section, evaluate, and adjust again until the desired extrusion is achieved.

- Document Your Settings: Keep a record of your nozzle diameters, filament types, and their corresponding optimal flow rates. This will save time and prevent repeated calibration efforts for known combinations.

The flow rate adjustment is not just about compensating for geometry; it’s about ensuring consistent volumetric output of molten material, which is paramount for the integrity and appearance of prints made with specialty filaments.

Nozzle Geometry and Design Factors

Beyond material and diameter, the physical shape and internal design of a nozzle play a crucial role in achieving successful prints with specialty filaments. These factors influence how the filament melts, flows, and adheres to the build plate and subsequent layers, directly impacting print quality and reliability. Understanding these geometric nuances allows for informed selection, especially when dealing with materials that have unique extrusion requirements.The internal geometry of a nozzle, including the orifice shape and the transition from the heat break, is critical for consistent filament extrusion.

Different shapes can affect the shear forces on the filament, influencing its melt homogeneity and flow rate. Similarly, the nozzle’s length and how it integrates with the heat break are paramount for managing temperature, particularly for high-temperature specialty filaments that demand precise thermal control to prevent degradation or incomplete melting.

Nozzle Orifice Shape and Filament Behavior

The shape of the nozzle’s exit orifice significantly impacts filament flow characteristics and the adhesion of the printed material. A well-designed orifice ensures that the molten filament exits the nozzle in a controlled and uniform manner, promoting better layer adhesion and surface finish.

- Rounded Orifice: A rounded or slightly bell-shaped orifice can help to reduce turbulence as the filament exits. This smoother flow can lead to more consistent extrusion and potentially better adhesion, as the molten plastic is less likely to be subjected to uneven shear forces. This design is often favored for materials where smooth surface finish and strong inter-layer bonding are priorities.

- Conical Orifice: A more sharply conical orifice can create higher shear forces, which might be beneficial for some viscous specialty filaments to ensure they are fully melted and flow easily. However, excessive tapering can lead to increased back-pressure and potential for oozing if not managed correctly. The angle of the cone is a critical parameter that needs to be matched to the filament’s rheological properties.

Nozzle Length and Heat Break Integration for High-Temperature Filaments

For high-temperature specialty filaments, maintaining a stable and accurate temperature profile throughout the extrusion path is essential. The length of the nozzle and its seamless integration with the heat break are key design elements that contribute to this thermal stability.

- Nozzle Length: A longer nozzle provides a greater surface area for heat transfer from the heater block to the filament. This extended melt zone can be advantageous for materials that require more time to reach their optimal printing temperature, especially those with high melting points or complex molecular structures. It allows for more thorough melting without overheating, which is crucial for preventing thermal degradation.

- Heat Break Integration: The heat break acts as a thermal barrier, preventing heat from traveling upwards into the cold end of the extruder. A well-designed integration between the nozzle and the heat break minimizes heat creep, which is the unwanted upward migration of heat. For high-temperature filaments, this is critical to prevent premature melting or jamming in the upper parts of the hotend, ensuring a clean and controlled extrusion process.

For instance, using a titanium or all-metal heat break in conjunction with a nozzle designed for efficient heat transfer can create a robust system for printing materials like PEEK or Ultem.

Geometric Features for Preventing Clogging with Composite Filaments

Composite filaments, which often contain abrasive fillers like carbon fiber, metal particles, or wood fibers, present unique challenges regarding nozzle clogging. Specific geometric features in nozzle design are engineered to mitigate these issues.

- Larger Orifice Diameter: While not strictly a geometric feature of the internal shape, using a nozzle with a larger internal diameter is a primary strategy. This provides more space for the composite particles to flow through without becoming lodged.

- Smooth Internal Surface Finish: A highly polished internal surface of the nozzle reduces friction and the likelihood of filament particles snagging and accumulating. This is particularly important for composite filaments where irregular particles can easily catch on rough surfaces.

- Tapered Transition: A smooth, gradual taper from the heat break into the nozzle orifice helps to prevent dead zones where molten material can stagnate and potentially degrade or form blockages. This ensures a consistent flow path for the composite material.

- Reinforced Nozzle Materials: While this relates more to material selection, it’s intrinsically linked to geometry. Nozzles made from hardened steel or other wear-resistant alloys are often designed with internal geometries that are more robust against the abrasive nature of composite filaments, maintaining their shape and smooth flow path over time.

Nozzle Geometry Selection Process for Print Speed and Extrusion Characteristics

Choosing the appropriate nozzle geometry involves a systematic approach that considers the interplay between printing speed and the specific extrusion behavior of the specialty filament being used. This process helps to optimize flow, minimize defects, and ensure print success.

The decision-making process can be structured as follows:

- Assess Filament Extrusion Characteristics:

- Viscosity: Is the filament highly viscous when molten, requiring more shear to flow, or does it flow easily?

- Melting Point: Does it require a high temperature, and is it prone to thermal degradation?

- Abrasiveness: Does it contain fillers that could wear down standard nozzles or cause clogging?

- Filament Diameter Consistency: Is the filament’s diameter uniform, or does it have variations that could affect flow?

- Consider Print Speed Requirements:

- High Speed: Requires a nozzle that can melt and extrude material rapidly and consistently without compromising layer adhesion or surface quality. This often benefits from geometries that promote efficient heat transfer and smooth flow.

- Low Speed: Allows for more controlled extrusion and potentially finer details. This might allow for geometries that focus on precision and adhesion over sheer volume of extrusion.

- Match Geometry to Needs:

- For High-Speed Printing of Viscous/High-Temp Filaments: Consider nozzles with a longer melt zone for thorough melting and a slightly more aggressive internal taper to facilitate faster flow, provided the material is not overly sensitive to shear. Hardened steel nozzles with polished interiors are often essential here due to potential abrasiveness and the need for durability at high throughput.

- For Detailed Printing with Standard or Slightly More Viscous Filaments: A standard rounded orifice or a gently conical nozzle might suffice. Focus on a smooth internal finish for consistent extrusion and good layer adhesion.

- For Abrasive Composite Filaments: Prioritize larger orifice diameters and nozzles made from wear-resistant materials. The internal geometry should be as smooth and free of sharp transitions as possible to minimize particle buildup.

- Test and Refine: It is always recommended to perform test prints with the chosen nozzle and filament combination. Monitor extrusion consistency, layer adhesion, surface finish, and signs of clogging. Minor adjustments to print speed, temperature, or retraction settings may be necessary to fine-tune performance.

Practical Steps for Selecting and Installing the Right Nozzle

Choosing the correct nozzle for your specialty filament printing journey is a critical step that directly impacts print quality, success rates, and the longevity of your equipment. This section provides a structured approach to guide you through the identification, selection, and installation process, ensuring you make informed decisions and execute the task with confidence.Navigating the diverse world of specialty filaments requires a methodical approach to nozzle selection.

By following a clear procedure, you can systematically identify the ideal nozzle for your specific printing needs, avoiding common pitfalls and maximizing your printing potential.

Identifying the Appropriate Nozzle for a Given Specialty Filament

The process of selecting the right nozzle begins with a thorough understanding of the filament’s properties and the demands it places on the printing hardware. This involves consulting filament manufacturer recommendations, considering abrasive properties, and understanding temperature requirements.

- Consult Filament Manufacturer Guidelines: Always begin by checking the recommended nozzle type and size provided by the filament manufacturer. These recommendations are based on extensive testing and are your most reliable starting point. Manufacturers often specify minimum nozzle diameters for abrasive filaments and recommend specific nozzle materials for high-temperature or chemically resistant filaments.

- Assess Filament Abrasiveness: Specialty filaments, particularly those with metallic, carbon fiber, or ceramic inclusions, are inherently abrasive. These additives can rapidly wear down standard brass nozzles. For such filaments, hardened steel, ruby, or tungsten carbide nozzles are essential to prevent premature wear and maintain print quality.

- Evaluate Filament Temperature Requirements: High-temperature filaments, such as PEEK or PEI (ULTEM), require nozzles capable of withstanding extreme temperatures without degradation or deformation. These filaments often necessitate all-metal hotends and nozzles made from materials like stainless steel, hardened steel, or specialized alloys designed for high-temperature performance.

- Consider Chemical Resistance: If you are printing with filaments that contain solvents or reactive chemicals, ensure your nozzle material offers adequate chemical resistance. Some specialty filaments might degrade or react with certain nozzle materials over time, leading to contamination or nozzle failure.

- Review Nozzle Diameter and Flow Rate Needs: The nozzle diameter significantly influences print speed and detail. Smaller diameters (e.g., 0.25mm – 0.4mm) are suitable for high-detail prints but can be prone to clogging with certain specialty filaments, especially those with larger particle sizes. Larger diameters (e.g., 0.6mm – 1.0mm+) are better for faster prints and can handle filaments with larger inclusions more effectively, but they reduce fine detail.

Always consider the filament’s extrusion requirements and the desired print outcome.

Checklist of Factors Before Purchasing a New Nozzle for Specialty Filament Printing

Before committing to a purchase, a comprehensive checklist ensures you are selecting the most suitable nozzle for your specific needs and printer. This proactive approach helps avoid costly mistakes and ensures compatibility and performance.To ensure you are making an informed decision when purchasing a new nozzle for specialty filament printing, consider the following critical factors:

- Filament Type: Identify the exact specialty filament(s) you intend to print with (e.g., carbon fiber reinforced nylon, wood-filled PLA, flexible TPU, high-temperature PEEK).

- Filament Abrasiveness Rating: Determine if the filament is standard, moderately abrasive, or highly abrasive. This dictates the required nozzle material.

- Required Nozzle Material: Based on abrasiveness and temperature, select from brass, stainless steel, hardened steel, ruby, tungsten carbide, or other specialized materials.

- Recommended Nozzle Diameter: Check manufacturer recommendations for optimal diameter, considering desired print detail versus speed and filament characteristics.

- Hotend Compatibility: Verify that the nozzle thread size and type (e.g., M6, V6) are compatible with your 3D printer’s hotend.

- Heat Resistance: Ensure the nozzle material can withstand the printing temperatures required by the specialty filament.

- Brand Reputation and Reviews: Research the manufacturer and read user reviews to gauge the quality and durability of the nozzle.

- Price vs. Durability: Balance the cost of the nozzle against its expected lifespan and performance with your intended filaments. Investing in a more durable nozzle can be more cost-effective in the long run for abrasive filaments.

- Ease of Cleaning: Consider how easy the nozzle material is to clean and maintain, especially if printing with sticky or residue-forming filaments.

Methods for Safely Removing and Installing a New Nozzle on a 3D Printer

The process of changing a nozzle, while seemingly straightforward, requires care and attention to detail to prevent damage to the hotend or the new nozzle. Following a precise procedure ensures a secure fit and optimal thermal transfer.Proper nozzle removal and installation are crucial for maintaining the integrity of your 3D printer’s hotend. The following steps Artikel a safe and effective method for performing this task.

It is important to note that procedures may vary slightly depending on your specific printer model and hotend design. Always refer to your printer’s manual for model-specific instructions.

Nozzle Removal

It is essential to perform nozzle changes when the hotend is heated to a specific temperature. This ensures that any residual filament within the nozzle melts, allowing for easier removal and preventing damage.

- Heat the Hotend: Carefully heat the hotend to a temperature slightly above the melting point of the filament you were last printing with, or a common printing temperature for your new filament (e.g., 200-240°C for PLA/PETG, or higher for ABS/Nylon). This step is critical as it softens any filament that might be lodged within the nozzle threads.

- Secure the Heater Block: To prevent torque from damaging the heater cartridge or thermistor, use two tools. One tool (typically an adjustable wrench or pliers) should grip the heater block firmly. The second tool (a socket wrench or appropriately sized wrench) is used to unscrew the nozzle.

- Unscrew the Old Nozzle: While holding the heater block steady with one tool, use the second tool to carefully unscrew the nozzle. Turn it counter-clockwise. Be prepared for some resistance, especially if the nozzle has been in place for a long time or has experienced heat creep.

- Allow to Cool: Once removed, place the hot nozzle on a heat-resistant surface. Allow it to cool completely before attempting to clean it or store it.

Nozzle Installation

Proper installation ensures a leak-free seal and optimal heat transfer. A slight overtightening can strip threads, while undertightening can lead to filament leaks.

- Clean the Heater Block Threads: Before installing the new nozzle, ensure the threads on the heater block are clean. You can use a small brass brush or a pick to remove any residual filament or debris.

- Thread the New Nozzle: Carefully thread the new nozzle into the heater block by hand, turning it clockwise. Ensure it threads smoothly without cross-threading. Screw it in until it is snug.

- Heat the Hotend Again: Heat the hotend to the same temperature used during removal (or a temperature appropriate for your new filament). This allows the nozzle and heater block to expand slightly, creating a tighter seal.

- Tighten the Nozzle: With the heater block secured as before, use your wrench to give the nozzle a final, gentle tightening. A common recommendation is a quarter to half turn past finger-tight. Avoid excessive force, as this can damage the threads. The goal is a secure, leak-free seal.

- Perform a Cold Pull (Optional but Recommended): After the nozzle has cooled slightly, a cold pull can help ensure a perfect seal and remove any potential internal debris. Heat the hotend to the printing temperature of the filament you plan to use, then load a small amount of filament. Once it begins to extrude, wait for the hotend to cool down significantly (e.g., to around 90-100°C for PLA).

Then, firmly and steadily pull the filament out of the hotend. This should remove any filament residue and confirm a good seal.

Guide for Performing Initial Test Prints to Validate Nozzle Performance with Specialty Filaments

After installing a new nozzle, especially for specialty filaments, it is imperative to conduct test prints to verify its performance and ensure optimal print quality. This process helps calibrate your printer and confirm the nozzle’s suitability for the material.To confirm that your newly installed nozzle is performing as expected with your chosen specialty filament, follow this guided approach to initial test prints.

This validation process is key to achieving successful and high-quality prints.

- Print a Temperature Tower: A temperature tower is an excellent first test print. It allows you to evaluate how the filament extrudes and prints at various temperatures with the new nozzle. Look for signs of stringing, blobbing, or poor layer adhesion at different temperature points. This will help you identify the optimal printing temperature for the filament with this specific nozzle.

- Print a Calibration Cube (XYZ Cube): A calibration cube is crucial for checking dimensional accuracy and overall print quality. It helps identify issues such as under-extrusion, over-extrusion, ringing, or warping that might be related to the nozzle’s flow rate or thermal properties. Measure the dimensions of the printed cube to ensure they match the expected values.

- Print a Small, Detailed Object: Select a small object with intricate details, sharp corners, and overhangs. This test will reveal the nozzle’s ability to reproduce fine features, handle sharp transitions, and manage overhangs effectively. Pay attention to the clarity of text, the sharpness of corners, and the smoothness of curved surfaces.

- Print a Benchy or Similar Functional Test Model: A 3D Benchy is a widely recognized benchmark print that tests various aspects of a 3D printer’s performance, including bridging, overhangs, and fine details. Printing a Benchy with your specialty filament and new nozzle will provide a comprehensive assessment of its capabilities.

- Monitor Extrusion and Flow: During these test prints, closely observe the extrusion process. Ensure that the filament is feeding smoothly and consistently without any skipping or grinding from the extruder gears. Check for any signs of filament leakage from the nozzle or hotend junction.

- Inspect for Layer Adhesion and Surface Finish: After each test print, carefully inspect the object for proper layer adhesion. The layers should be well-bonded, and the surface finish should be smooth and consistent, free from significant defects like z-wobble or inconsistent extrusion lines.

- Adjust Slicer Settings as Needed: Based on the results of your test prints, make necessary adjustments to your slicer settings. This may include fine-tuning printing temperature, retraction settings, print speed, or flow rate. Document these changes for future reference.

Maintenance and Longevity of Specialty Filament Nozzles

Maintaining your specialty filament nozzles is crucial for consistent print quality and to maximize their operational lifespan. Abrasive filaments, in particular, can rapidly wear down standard brass nozzles, leading to under-extrusion and a decline in print accuracy. Proactive maintenance and a keen eye for wear signs will save you time, filament, and frustration.This section will guide you through the essential aspects of nozzle care, from establishing a regular maintenance routine to understanding when it’s time for a replacement.

Proper attention to these details ensures your specialized printing endeavors continue to yield excellent results.

Routine Maintenance Schedule for Abrasive Filament Nozzles

Establishing a consistent maintenance schedule is paramount when working with abrasive filaments such as carbon fiber, metal-filled, wood-filled, or glow-in-the-dark materials. These filaments contain particles that act like sandpaper, eroding the inner surfaces of the nozzle over time. A proactive approach will prevent gradual degradation and unexpected failures.A recommended maintenance schedule should incorporate the following:

- After Every 10-20 Hours of Printing: Perform a basic cleaning to remove any residual filament or debris.

- After Every 50-100 Hours of Printing: Conduct a more thorough cleaning and inspect the nozzle tip for visible signs of wear.

- Monthly or as Needed: For heavy users or those printing particularly abrasive filaments, consider a deep cleaning or even nozzle replacement.

- Immediately After Experiencing Clogs or Extrusion Issues: Regardless of the schedule, any printing anomaly warrants immediate inspection and cleaning.

Effective Cleaning Techniques to Prevent Clogs and Maintain Optimal Extrusion

Keeping your specialty filament nozzles clean is fundamental to preventing clogs and ensuring smooth, consistent extrusion. The techniques you employ will depend on the type of nozzle and the nature of the blockage or residue.Several effective cleaning methods can be utilized:

- Cold Pull (Atomic Pull): This is an excellent technique for removing stubborn filament residue, especially with high-temperature filaments. Heat the nozzle to a temperature slightly above the filament’s melting point, then slowly pull the filament out by hand or with pliers. As it cools and solidifies, it can pull solidified debris out with it.

- Nozzle Cleaning Needles: For minor clogs or to clear the tip, use specialized nozzle cleaning needles. Gently insert the needle into the nozzle tip while it’s hot to dislodge any obstructions. Be cautious not to damage the nozzle’s inner diameter.

- Brass Wire Brush: A brass wire brush can be used to gently scrub the exterior of the nozzle tip while it is hot, removing any fused filament buildup. Avoid using steel brushes, as they can scratch and damage the nozzle.

- Heat and Compressed Air: For some types of residue, heating the nozzle and then using a blast of compressed air can help dislodge particles. Ensure you are in a well-ventilated area.

- Acetone or Isopropyl Alcohol: For certain filament types like ABS or PLA, soaking the nozzle (after removal from the hotend) in a suitable solvent like acetone or isopropyl alcohol can help dissolve residual plastic. Always ensure the nozzle is cool before soaking and thoroughly dry it before reinstallation.

When cleaning, always ensure the nozzle is heated to a temperature that allows the filament to be pliable but not so hot that it poses an immediate burn risk. After cleaning, it is advisable to extrude a small amount of filament to confirm clear flow.

Signs That Indicate a Nozzle is Worn Out and Requires Replacement

Recognizing the signs of a worn-out nozzle is critical to avoid the frustration of print failures and to maintain the integrity of your prints. Abrasive filaments, in particular, cause wear that manifests in specific ways.Key indicators that your nozzle needs replacement include:

- Increased Filament Usage: If you find yourself needing to increase retraction distances or extrusion multipliers significantly to achieve proper extrusion, the nozzle’s inner diameter may have enlarged due to wear.

- Under-Extrusion: This is one of the most common signs. Prints will exhibit gaps between lines, stringing, poor layer adhesion, and overall weakness due to insufficient material being deposited.

- Inconsistent Extrusion: You might observe intermittent filament flow, where the extruder struggles to push filament through, leading to skipped steps or pulsing extrusion.

- Loss of Detail and Surface Finish Degradation: As the nozzle tip wears down and becomes less defined, the sharpness and detail of your prints will suffer. Surface textures may become rougher or less consistent.

- Changes in Nozzle Tip Shape: Visually inspect the nozzle tip. A worn nozzle will often appear rounded or deformed, losing its precise conical or cylindrical shape. This deformation can affect the way the filament is laid down.

- Increased Printing Time for Same Models: While not always a direct indicator, if you notice that prints are taking noticeably longer to complete with the same settings, it could suggest the nozzle is not extruding efficiently.

The lifespan of a brass nozzle with abrasive filaments can be as short as 50-200 hours of printing, whereas hardened steel or ruby-tipped nozzles can last for thousands of hours under similar conditions.

Strategies for Extending the Lifespan of Specialty Filament Nozzles Through Proper Care and Handling

Maximizing the lifespan of your specialty filament nozzles is achievable through a combination of careful material selection, diligent maintenance, and proper handling practices. Investing in higher-quality, wear-resistant nozzles can be a significant factor, but even standard nozzles can last longer with the right approach.Effective strategies include:

- Use Wear-Resistant Nozzle Materials: For abrasive filaments, prioritize nozzles made from hardened steel, ruby, tungsten carbide, or other advanced composite materials. While these are more expensive upfront, their longevity significantly outweighs the cost of frequent brass nozzle replacements.

- Minimize Contact with Abrasive Filaments When Possible: If your print involves both standard and abrasive filaments, consider using a standard nozzle for the standard parts and swapping to a wear-resistant nozzle only when printing the abrasive sections.

- Maintain Optimal Printing Temperatures: Printing at excessively high temperatures can sometimes accelerate wear, especially with certain filament and nozzle material combinations. Adhere to the filament manufacturer’s recommended temperature range.

- Proper Storage: When not in use, store nozzles in a clean, dry environment. Protect the tip from accidental damage or contamination.

- Gentle Cleaning Practices: Avoid aggressive cleaning methods that could scratch or deform the nozzle. Always use appropriate tools and techniques as Artikeld in the cleaning section.

- Regular Inspection: Make it a habit to visually inspect your nozzle tip before and after printing, especially when using new or particularly abrasive filaments. Early detection of wear is key.

- Calibrate Flow Rate Regularly: Even with a good nozzle, flow rate can drift due to wear. Periodically recalibrating your extruder’s E-steps and flow rate can help compensate for minor wear and ensure consistent extrusion.

By implementing these strategies, you can significantly prolong the functional life of your specialty filament nozzles, ensuring reliable and high-quality 3D printing for a wider range of materials.

Illustrative Scenarios of Nozzle Selection

Understanding the theoretical aspects of nozzle selection is crucial, but seeing how these principles apply in real-world printing scenarios can solidify your understanding and help you make informed decisions. This section will walk through common situations, providing practical examples and thought processes to guide your nozzle choices.To effectively choose a nozzle for specialty filaments, it’s beneficial to have a comparative overview of their typical requirements.

This table highlights key differences and considerations for some commonly encountered specialty filaments.

| Filament Type | Common Particle Size | Recommended Nozzle Material | Typical Nozzle Diameter Range | Key Considerations |

|---|---|---|---|---|

| Carbon Fiber Reinforced PLA | 0.1-0.3 mm | Hardened Steel | 0.4 – 0.6 mm | Exceptional wear resistance is paramount due to the abrasive nature of carbon fibers. While hardened steel is durable, it can sometimes lead to brittleness in prints if extrusion parameters are not optimized. |

| Wood-Filled PLA | 0.2-0.5 mm | Hardened Steel | 0.4 – 0.8 mm | The larger particle size increases the risk of nozzle clogging. A larger nozzle diameter can mitigate this. Surface finish is also a significant factor, and the nozzle’s internal geometry can influence the wood-like texture. |

| Flexible TPU | N/A (viscous) | Brass (often) | 0.4 – 0.6 mm | While not abrasive in the particulate sense, the high viscosity of TPU requires careful consideration of extrusion speed and retraction settings to prevent stringing and jamming. Brass is generally sufficient unless printing at extremely high temperatures where more durable materials might be considered. |

Metal-Filled Filament Nozzle Selection Scenario

Imagine a user wanting to print a decorative object with a bronze-filled PLA filament. This filament contains fine metallic particles that are highly abrasive. The user’s initial thought process would be: “This filament is definitely going to wear down a standard brass nozzle quickly.” Therefore, the primary consideration becomes wear resistance.The user would then consult their filament’s manufacturer recommendations or general 3D printing knowledge bases.

These sources would strongly advise against using brass nozzles for metal-filled filaments. The next logical step is to consider more durable materials. Hardened steel is the most common and effective choice for abrasive filaments like metal-filled ones.Regarding nozzle diameter, the user might initially think of their standard 0.4 mm nozzle. However, metal-filled filaments, while not having large discrete particles, can still pose a risk of clogging if the flow path is too narrow, especially with longer print times.

A slightly larger diameter, perhaps 0.5 mm or 0.6 mm, could offer a better balance between fine detail and reliable extrusion, reducing the likelihood of jams. The internal geometry of the nozzle is also important; a well-designed nozzle with a smooth internal finish will further minimize the chances of filament snagging and subsequent clogging. The user would opt for a hardened steel nozzle, likely in the 0.4 mm to 0.6 mm range, prioritizing wear resistance and a smooth internal finish.

Troubleshooting Persistent Clogging with High-Temperature Specialty Filaments

Consider a scenario where a user is consistently experiencing nozzle clogs when printing with a high-temperature specialty filament, such as PEEK or PEI, which require significantly higher printing temperatures than standard PLA or ABS. The user has already tried increasing retraction distances and reducing print speed, but the problem persists.The thought process here would shift towards the nozzle’s ability to withstand and efficiently handle these extreme temperatures, as well as the potential for material degradation or adhesion within the nozzle.

A standard brass nozzle would be completely unsuitable, as it would likely soften and deform at the required temperatures, leading to extrusion inconsistencies and rapid wear.The user would first confirm they are using a nozzle made from a material designed for high-temperature printing. This typically means hardened steel, stainless steel, or even more exotic materials like ruby-tipped nozzles for extreme abrasion and heat resistance.

If they are already using a hardened steel nozzle, the next step is to examine its internal condition.A persistent clogging issue, even with the correct material, could indicate internal wear or a buildup of degraded filament material. Over time, the internal surface of the nozzle can become rough or develop a “baked-on” layer of filament residue, creating friction and constricting the filament path.

In such cases, the solution might not just be selecting a new nozzle, but ensuring the replacement is of high quality with a very smooth internal finish.The user would then consider the nozzle diameter again. While a larger diameter can help with particle-filled filaments, for high-temperature filaments, consistency of extrusion is key. A 0.4 mm nozzle might be appropriate if the filament itself is not abrasive, but if the clogging is due to heat-related issues or material degradation, a slightly larger nozzle (e.g., 0.5 mm) could provide a more forgiving flow path, allowing for more consistent melting and extrusion without immediate obstruction.

They might also investigate if the nozzle’s heat break is adequately designed to prevent heat creep into the cold end, which can also cause clogs. Ultimately, troubleshooting persistent clogging with high-temperature filaments often involves a combination of selecting a robust, high-temperature-rated nozzle material, ensuring its internal geometry is smooth, and verifying that the entire hotend assembly is functioning optimally.

Conclusion

By carefully considering the interplay between your chosen specialty filament and the optimal nozzle, you can significantly enhance your 3D printing experience. From selecting the most durable material to fine-tuning diameter and geometry, each step contributes to smoother prints, fewer failures, and the realization of your most ambitious projects. Embrace this knowledge to elevate your prints and explore the vast landscape of specialty filament possibilities with confidence and precision.