As How to Split a Large Model into Smaller Printable Parts takes center stage, this opening passage beckons readers into a world crafted with good knowledge, ensuring a reading experience that is both absorbing and distinctly original.

Embarking on a 3D printing project often involves working with models that exceed the capabilities of standard printers. Fortunately, the process of dividing these large digital creations into manageable segments is not only feasible but also unlocks a new realm of possibilities for makers. This guide will navigate you through the essential steps, from understanding why splitting is necessary to mastering the techniques for seamless assembly and finishing, ensuring your ambitious projects come to life with precision and ease.

Understanding the Need for Model Splitting

Large 3D models, while impressive in their digital form, often present significant challenges when it comes to physical realization through additive manufacturing. The process of 3D printing involves translating a digital design into a tangible object, layer by painstaking layer. When a model exceeds the capabilities of a standard 3D printer, a crucial step known as model splitting becomes not just beneficial, but essential for successful fabrication.

This process involves dividing a complex, oversized digital model into smaller, manageable components that can be individually printed and subsequently assembled.The necessity for splitting arises from a confluence of practical limitations inherent in most consumer and even many professional-grade 3D printers. These machines, despite their advancements, have finite build volumes, which directly restrict the maximum size of any single object they can produce.

Beyond physical dimensions, other factors such as print bed adhesion, structural integrity during printing, and the sheer time commitment for a single, massive print also contribute to the need for segmentation. Successfully navigating these limitations through thoughtful model splitting opens up a world of possibilities for creating larger, more intricate, and more detailed physical objects.

Printer Build Volume Limitations

One of the most fundamental reasons for splitting a large 3D model is the physical constraint of the 3D printer’s build volume. This refers to the maximum dimensions (typically length, width, and height) of an object that can be printed within the printer’s enclosed or open print area. If a desired model, in its entirety, exceeds these dimensions, it simply cannot be printed as a single piece.

For instance, a life-sized replica of a human bust might require a build volume far exceeding that of a desktop printer.

The build volume is the absolute maximum physical boundary within which a 3D printer can operate.

Many standard desktop 3D printers have build volumes ranging from approximately 100x100x100 mm to 300x300x300 mm. Professional-grade printers can offer larger volumes, but even these have limits. A model that is 500 mm in its longest dimension will not fit on a printer with a maximum build dimension of 300 mm. This necessitates breaking down the model into sections, each of which individually fits within the printer’s build envelope.

Structural Integrity and Print Success

Printing very large objects as a single piece can also compromise structural integrity during the printing process itself. Tall, slender parts are prone to warping, detaching from the print bed, or experiencing layer adhesion failures due to the forces exerted by the moving print head, cooling effects, and the weight of accumulating material. Additionally, extremely large prints require a significant amount of filament and uninterrupted printing time, increasing the risk of print failures due to power outages, filament run-out, or mechanical issues.Splitting a model into smaller, more robust parts can significantly improve the chances of a successful print.

Smaller components are generally easier to secure to the print bed, experience less stress during printing, and require less time per piece. This modular approach also allows for easier troubleshooting; if one small part fails, only that section needs to be reprinted, rather than the entire large object. Furthermore, it allows for strategic orientation of each part on the build plate to optimize for strength, detail, and minimal support material.

Ease of Printing and Assembly

Beyond overcoming physical limitations, splitting a large model offers considerable advantages in terms of the overall printing and assembly experience. Smaller parts are more manageable to handle, remove from the print bed, and post-process. They also require less filament and generally print faster than a single, monolithic object of equivalent volume, leading to reduced material costs and quicker turnaround times.The assembly process itself can be designed to be straightforward.

By incorporating interlocking features, registration pins, or flat mating surfaces into the design of the individual parts, the alignment and joining of printed components become more precise and less prone to error. This is particularly important for models that require a high degree of accuracy and a seamless final appearance. For example, a large architectural model might be split into building sections, floors, or even individual facade elements, each designed to slot or glue together with minimal fuss.

Projects Benefiting from Model Segmentation

A wide array of projects can greatly benefit from the segmentation of large 3D models. This technique is invaluable for creating:

- Large-scale props and replicas: Whether it’s a movie prop, a museum display piece, or a detailed replica of a historical artifact, these often exceed standard printer dimensions.

- Architectural models: Detailed representations of buildings or urban landscapes are frequently too large to print as a single unit and are best segmented by floor, wing, or section.

- Life-sized character models or statues: For cosplay, art installations, or display purposes, full-scale figures must be divided into manageable segments for printing and subsequent assembly.

- Functional prototypes and enclosures: Large industrial prototypes, custom machine enclosures, or complex robotic chassis often require splitting to fit within printer build volumes and to facilitate internal component access.

- Furniture or large decorative items: Elements of custom furniture, large vases, or decorative wall art can be printed in sections and then joined to create the final, impressive piece.

The ability to split models democratizes the creation of large-scale objects, making them accessible to individuals and businesses with standard 3D printing equipment. It transforms ambitious designs from theoretical possibilities into achievable realities through intelligent planning and execution.

Software Tools for Model Segmentation

Selecting the right software is a crucial step in preparing your large 3D models for printing. These tools offer the functionality to divide complex designs into manageable, printable sections, ensuring accuracy and ease of assembly. Fortunately, a variety of software solutions are available, catering to different user needs and budgets.The process of segmenting a 3D model involves identifying natural break points, adding registration keys for alignment, and sometimes reinforcing the model’s structure.

These software applications streamline this process, allowing for precise cuts and modifications that are essential for successful 3D printing.

Popular Software Applications for Model Splitting

Numerous software applications are widely used by 3D printing enthusiasts and professionals for model segmentation. These tools range in complexity and features, offering solutions for both beginners and advanced users.

- Meshmixer: A powerful, free tool from Autodesk, widely recognized for its comprehensive mesh editing capabilities, including robust tools for slicing and hollowing models.

- Blender: A free and open-source 3D creation suite that, while not solely focused on slicing, offers extensive modeling and editing tools that can be leveraged for manual model segmentation.

- 3D Builder: A free application from Microsoft, often pre-installed on Windows 10 and 11, that provides straightforward tools for repairing, cutting, and splitting models.

- Netfabb: A professional-grade software solution from Autodesk, offering advanced features for model preparation, including automated splitting, part creation, and print simulation.

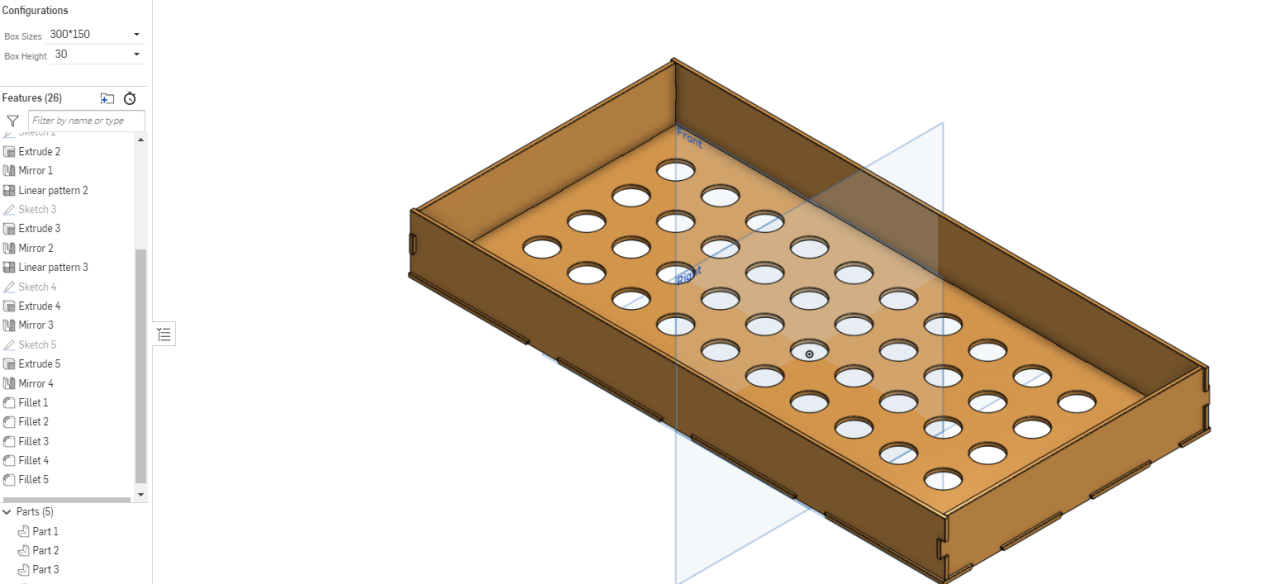

- Fusion 360: While primarily a CAD software, Fusion 360’s parametric modeling capabilities allow for precise splitting of models, especially those designed with engineering in mind. It is available for free for hobbyists and startups.

Comparative Overview of Free and Paid Software Options

The choice between free and paid software often depends on the complexity of your models, the frequency of your 3D printing projects, and the level of precision and automation required.

Free Software Options:

Free software solutions are excellent starting points, offering robust functionalities for most common model splitting tasks. They are ideal for hobbyists, students, and those new to 3D printing.

- Meshmixer: Stands out for its advanced mesh manipulation tools, including intelligent slicing based on planes, sculpting, and surface detection. Its “Inspector” tool is also invaluable for identifying and repairing mesh errors before splitting.

- Blender: While requiring a steeper learning curve, Blender provides unparalleled control. Users can manually cut models using boolean operations, create custom slicing planes, and even animate the separation process for complex assemblies.

- 3D Builder: Offers a user-friendly interface with simple drag-and-drop functionality for basic splitting. It’s particularly good for quick repairs and straightforward cuts, making it accessible for beginners.

Paid Software Options:

Paid software typically offers more advanced features, automation, and dedicated support, making them suitable for professional use, complex projects, and businesses.

- Netfabb: This is a professional suite designed for additive manufacturing. Its automated splitting algorithms can quickly divide large models into multiple parts based on user-defined criteria, such as print bed size or structural integrity. It also excels in creating interlocking features and adding internal supports.

- Fusion 360: For CAD-based models, Fusion 360 offers precise control over splitting using its robust modeling tools. You can define exact cut planes, create custom joinery, and ensure precise fits between parts.

Core Functionalities Facilitating Splitting

These software tools employ several key functionalities to enable effective model segmentation. Understanding these features will help you choose and utilize the software more efficiently.

- Plane Cutting: This is the most fundamental method, allowing users to slice a model along a flat plane. Many tools offer options to orient the plane in any direction and to add a gap between the cut surfaces.

- Boolean Operations: Advanced tools utilize boolean operations (union, subtract, intersect) to precisely cut one mesh with another, allowing for complex, non-planar cuts and the creation of interlocking features.

- Automatic Segmentation: Professional software often includes algorithms that can automatically suggest or perform splits based on model size, print bed dimensions, or user-defined constraints.

- Registration Keys and Alignment Features: To ensure parts fit together accurately after printing, many tools allow for the addition of pegs, sockets, or interlocking geometries.

- Hollowing: While not strictly splitting, hollowing models can reduce print time and material usage. Some splitting tools integrate hollowing features to prepare parts for printing.

- Shell Generation: For creating interlocking parts or adding structural integrity, some software can generate shells around the cut surfaces.

Step-by-Step Procedure for Preparing a Model for Splitting (Using Meshmixer)

Meshmixer is an excellent choice for its power and free availability. Here’s a general procedure for preparing a model for splitting using this software.

- Import Your Model: Open Meshmixer and import your large 3D model by going to File > Import.

- Inspect and Repair the Mesh: Before splitting, it’s crucial to ensure your model is watertight and free of errors. Go to Analysis > Inspector. If errors are found, click “Auto Repair All” or manually address them.

- Select the Plane Cut Tool: Navigate to Edit > Plane Cut. A cutting plane will appear over your model.

- Position and Orient the Cutting Plane: Use the manipulation gizmos to move, rotate, and scale the cutting plane to determine where you want to divide the model. You can align the plane with axes or custom orientations.

- Choose Cut Type and Options:

- Select “Cut Away” to remove one side of the model.

- Select “Cut and Keep Both” to create two separate pieces.

- Enable “Make Manifold” to ensure the newly created cut surfaces are solid.

- Consider enabling “Add Thickness” if you need to create a shell or ensure a minimum wall thickness for the cut surfaces.

- Add Registration Keys (Optional but Recommended):

- After making the initial cut, you may want to add registration keys for alignment.

- Use the “Sphere” or “Cylinder” primitives from the “Edit > Transform > Add Sphere/Cylinder” menu.

- Position these primitives on the cut surfaces so they interlock when the parts are assembled.

- You can then use boolean operations (Edit > Combine) to merge these keys with the respective model parts.

- Apply the Cut: Once satisfied with the positioning and options, click “Accept” to perform the cut.

- Separate the Parts: If you chose “Cut and Keep Both,” you will now have two distinct meshes. You can select each part individually and export them using File > Export.

- Export Each Part: Save each segmented part as a separate STL or OBJ file, ready for slicing in your 3D printer’s software.

Splitting Strategies and Techniques

Successfully splitting a large 3D model into smaller, printable parts is a crucial step in bringing complex designs to life. This process requires careful planning and the application of specific techniques to ensure each segment is not only printable but also seamlessly reassembled. The goal is to create a set of pieces that are manageable for your 3D printer while maintaining the overall integrity and aesthetic of the original model.Different approaches exist for dividing a complex model, each suited to varying model types and desired outcomes.

The choice of strategy significantly impacts the ease of printing, post-processing, and final assembly. It’s about finding the right balance between minimizing print time per part, reducing the need for extensive support structures, and ensuring a strong, well-aligned final product.

Model Division Approaches

There are several primary methods for dividing a large 3D model into smaller components, each with its own advantages. Understanding these approaches allows you to select the most appropriate one for your specific project.

- Geometric Slicing: This is the most straightforward method, involving cutting the model along simple geometric planes, such as horizontal, vertical, or angled cuts. It’s often the quickest way to generate parts but may result in less aesthetically pleasing seams or require significant post-processing to hide the divisions.

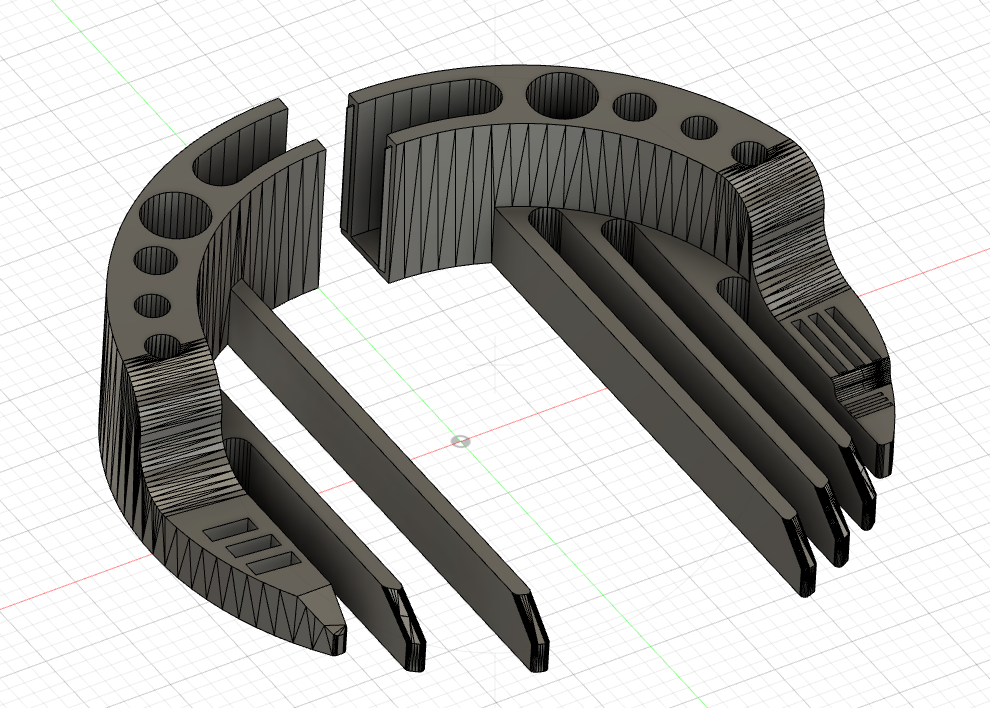

- Feature-Based Splitting: This technique involves dividing the model along natural breaks or existing features, like panel lines, decorative elements, or functional components. This approach can lead to more visually integrated seams, as the cuts often follow the model’s design lines.

- Sub-Assembly Splitting: For models composed of distinct functional or decorative sub-assemblies (e.g., a vehicle with separate wheels, doors, and chassis), splitting along these natural sub-assembly boundaries is highly effective. This simplifies printing and assembly as each sub-assembly can be treated as an independent unit.

- Print Orientation Optimization: Sometimes, the most practical way to split a model is to consider how each part will be oriented on the print bed. This might involve splitting a large, flat object into multiple smaller pieces that can be printed lying down to minimize height and reduce the need for supports.

Creating Clean and Printable Cuts

The quality of the cut surfaces directly impacts the ease of assembly and the final appearance of the printed model. Well-executed cuts minimize the need for extensive sanding and filling, leading to a cleaner final product.

- Consider Print Orientation: When planning cuts, think about how each resulting piece will be oriented on the print bed. Cuts that result in large, flat surfaces can be problematic if they need to be printed vertically, often requiring extensive support. Whenever possible, aim for cuts that allow parts to be printed with their largest flat surfaces down.

- Minimize Overhangs and Steep Angles: Design cuts that avoid creating steep overhangs or large unsupported areas within the cut surfaces themselves. This reduces the need for support material on the mating surfaces, which can be difficult to remove cleanly and can mar the finish.

- Strategic Placement of Cuts: Place cuts in areas that are less visually prominent or where seams can be naturally hidden by subsequent assembly steps or design features. For instance, splitting a character model at the waist or shoulders is often less noticeable than cutting through the middle of their face.

- Adding Chamfers or Fillets: Introducing small chamfers or fillets along the cut edges can help to mask slight misalignments and make the joining process easier. These small bevels or rounded edges can also provide a slight tolerance for variations in printing.

Adding Registration Keys and Alignment Features

To ensure precise alignment of the split parts during assembly, incorporating registration keys or alignment features is essential. These elements act like puzzle pieces, guiding the segments into their correct positions and providing mechanical strength to the joints.

Types of Registration Keys

Registration keys are small protrusions or indentations designed to interlock two or more parts. They are typically designed to be printed as part of one of the segments and fit snugly into a corresponding recess on the mating segment.

- Pegs and Holes: The most common type involves printing cylindrical pegs on one part that fit into corresponding holes on another. These can be simple cylinders or tapered shapes for easier insertion.

- Dovetail Joints: For stronger, more positive locking, dovetail joints can be incorporated. These are angled slots and protrusions that resist pulling apart.

- Keyways and Tabs: Similar to pegs and holes, but often rectangular or trapezoidal in shape, these provide alignment along a specific axis and can offer a more robust connection.

- Alignment Pins: These are similar to pegs but are often used in conjunction with other joining methods, providing a critical point of alignment.

When designing these features, ensure they have appropriate tolerances. A common practice is to slightly oversize the receiving feature (e.g., the hole or slot) by a small amount (e.g., 0.1-0.2 mm) to account for printer inaccuracies and filament expansion, ensuring a snug but not impossible fit.

Ensuring Structural Integrity After Splitting

Splitting a model can compromise its overall structural integrity. It’s important to implement strategies that maintain or even enhance the strength of the assembled object.

- Reinforce Joints: Wherever possible, design the split to allow for internal reinforcement. This could involve creating channels for glue to flow into, or designing the segments so that they can be further reinforced with internal rods, pins, or even magnets after assembly.

- Minimize Thin or Fragile Sections: Be mindful of how the splitting process might create thin or delicate areas in the individual parts. If necessary, adjust the cut lines or add reinforcing structures to these areas.

- Consider Load-Bearing Points: If the model is intended to bear weight or withstand stress, pay close attention to where the splits occur in relation to these load-bearing points. Aim to keep critical structural elements intact or design the joints to be exceptionally strong.

- Use Appropriate Adhesives: The choice of adhesive is critical. Cyanoacrylate (super glue) is excellent for quick bonds, while epoxy offers superior strength and gap-filling capabilities. For some plastics, solvent-based cements can create a very strong, fused bond.

Checklist of Considerations Before Initiating the Splitting Process

Before you begin dividing your model, a thorough review of these points will help ensure a smoother and more successful outcome.

| Consideration | Description | Importance |

|---|---|---|

| Model Complexity | Assess the overall geometry, number of distinct parts, and intricate details. | Determines the difficulty of splitting and the number of segments required. |

| Printer Capabilities | Note the maximum build volume, print resolution, and material compatibility. | Ensures the size of individual parts and the quality of the final print. |

| Assembly Method | Plan how the parts will be joined: glue, screws, magnets, or other methods. | Influences the design of mating surfaces and the need for alignment features. |

| Desired Finish | Consider whether the seams will be visible and the effort required for post-processing. | Guides decisions on cut placement and the use of aesthetic features. |

| Structural Requirements | Evaluate if the model needs to be strong, load-bearing, or purely decorative. | Dictates the need for reinforcement and robust joint design. |

| Support Material Needs | Anticipate how splitting will affect the amount and placement of support structures. | Aims to minimize support material, especially on visible surfaces. |

| Print Time per Part | Balance the number of parts against the time required to print each one. | Optimizes the overall printing duration and manageability of the project. |

| Software Capabilities | Ensure your chosen software can handle the splitting operations and add necessary features. | Verifies that the tools are adequate for the task. |

Preparing Split Parts for Printing

Once your large model has been successfully segmented into smaller, manageable pieces, the next crucial step is to prepare these individual parts for successful 3D printing. This involves meticulous attention to detail in scaling, orientation, and print settings to ensure that when assembled, the final model retains its intended dimensions and integrity. Careful preparation at this stage significantly reduces post-processing time and improves the overall quality of your printed object.The process of preparing split parts for printing is multifaceted, requiring a thoughtful approach to each element.

From ensuring that each piece scales correctly to fit the overall design, to optimizing its placement on the print bed for maximum efficiency and quality, every decision impacts the final outcome. This section will guide you through these essential steps, empowering you to achieve professional-grade results with your split models.

Scaling Considerations for Individual Printed Parts

Maintaining the overall dimensions of the original large model is paramount when printing its constituent parts. If your segmentation software automatically scaled down the pieces, or if you manually adjusted them, it’s vital to ensure that each part is scaled back to its original proportion relative to the whole. This is typically achieved by ensuring that the scaling factor applied to each part is consistent with the original model’s scale.

For example, if the original model was designed at a 1:1 scale, each printed part should also be scaled at 1:1 relative to its original size within the larger assembly.When splitting a model, especially for printers with limited build volumes, you might need to scale the entire model down before splitting. In such cases, the scaling factor is applied uniformly to all parts.

For instance, if you decide to scale the entire model down by 50% to fit your printer, each individual part must also be printed at that same 50% scale.

Accurate scaling is the foundation of a successful multi-part print. A deviation of even a small percentage in one part can lead to significant assembly issues.

It is essential to verify the dimensions of each split part against the original model’s specifications or by re-assembling a virtual representation in your slicing software before committing to printing. Many slicing programs allow you to import all parts and check their fit and overall dimensions before slicing.

Optimizing Part Orientation on the Print Bed

The orientation of each split part on the print bed significantly impacts print quality, strength, and the amount of support material required. The goal is to position each piece in a way that minimizes overhangs, maximizes surface finish on visible areas, and utilizes the printer’s capabilities effectively.Consider the following points when orienting your parts:

- Minimize Overhangs: Orient parts so that the largest flat surfaces are facing downwards on the print bed. This reduces the need for extensive support structures, which can mar surface finish and are time-consuming to remove.

- Surface Quality: Place the most aesthetically important surfaces facing upwards or at an angle that requires minimal support. The top layers of a print are generally of higher quality than those printed on supports.

- Layer Line Visibility: For curved or detailed surfaces, orient the part so that layer lines are less noticeable. Sometimes, rotating a part by 45 degrees can help disguise the appearance of layer lines.

- Strength Considerations: For parts that will bear weight or stress, orient them so that the layer lines are not perpendicular to the primary direction of force. 3D prints are weakest between layers.

- Bed Adhesion: Ensure a good portion of the part’s surface area is in contact with the print bed to prevent warping or detachment during printing. Large, flat surfaces are ideal for bed adhesion.

When dealing with complex geometries, it’s often beneficial to experiment with different orientations in your slicing software. Previewing the sliced model with supports enabled for each orientation can help you make the most informed decision.

Selecting Appropriate Print Settings for Each Segment

Print settings play a critical role in the quality and success of printing individual model segments. While general settings can be applied, fine-tuning them for specific parts can yield superior results.Here’s a breakdown of key settings and their considerations:

Layer Height

The layer height determines the resolution and speed of your print.

- For high-detail parts: A smaller layer height (e.g., 0.1mm to 0.15mm) will produce smoother surfaces and capture finer details, but will significantly increase print time.

- For less detailed or internal parts: A larger layer height (e.g., 0.2mm to 0.3mm) can speed up printing considerably with minimal impact on overall quality, especially if the surfaces will not be highly visible or will be sanded/painted.

Infill

Infill determines the internal structure of the printed part, affecting its strength, weight, and material consumption.

- For structural integrity: Higher infill percentages (e.g., 20-40%) are recommended for parts that need to be strong or support weight.

- For display models or less stressed parts: Lower infill percentages (e.g., 5-15%) are sufficient and save material and print time.

- Consider infill patterns: Different infill patterns (e.g., grid, gyroid, cubic) offer varying strengths and print efficiencies. Gyroid is often a good balance of strength and speed.

It is also advisable to consider print speed, retraction settings, and cooling for each part, especially if certain parts have very fine features or delicate overhangs. Some slicing software allows you to set different print speeds for different parts within the same print job.

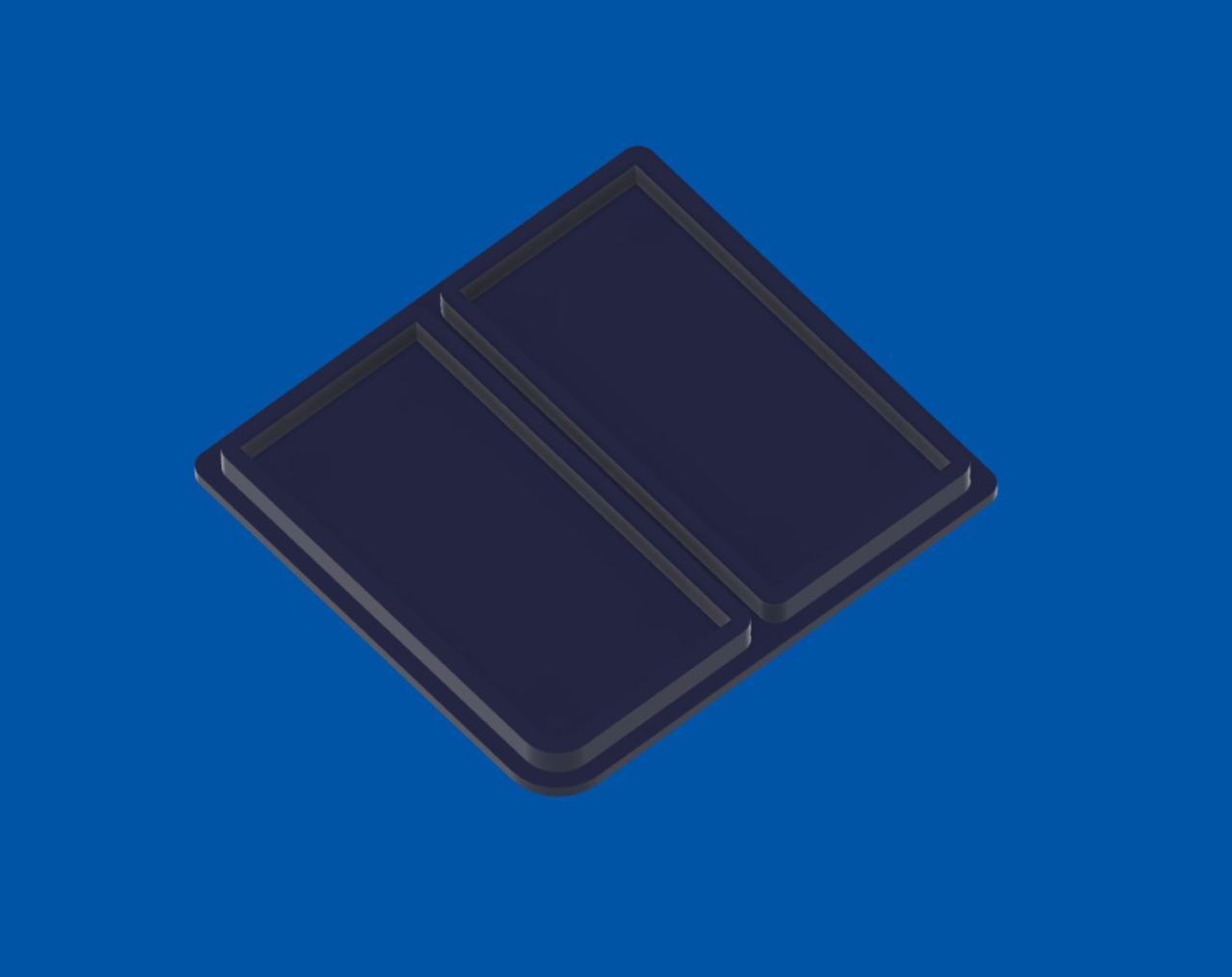

Assigning Different Materials or Colors to Specific Parts

For models that benefit from distinct colors or material properties, assigning these to specific parts before printing is a straightforward yet impactful process. This is particularly relevant for multi-material printers or for models where manual painting or post-processing will be extensive.The process typically involves:

- Material Assignment: In your slicing software, you can often assign specific materials to individual parts or groups of parts. This is crucial for printers capable of extruding multiple filaments. For example, you might print a character’s clothing in one color and their skin in another, or print functional parts with a more durable material than decorative ones.

- Color Assignment: For single-material printers, the assignment of color is usually done by changing the filament during the print process at a specific layer height. Slicing software often has a feature to insert a “pause” or “filament change” command at a designated layer. This allows you to manually swap out the filament to a different color for subsequent layers of a part, or to print entire parts in different colors sequentially.

- Considerations for Multi-Part Assembly: If you plan to paint the parts after printing, consider using a primer-compatible material for all parts to ensure consistent paint adhesion. If using soluble supports, ensure the support material is compatible with your primary printing material.

The ability to assign different materials or colors to specific parts opens up a world of creative possibilities, allowing for more realistic and visually striking models without extensive post-processing.

For instance, a detailed miniature figure could have its base printed in a wood-effect filament, the figure itself in a neutral grey for easy painting, and small accessories like weapons or jewelry printed in metallic filaments directly. This pre-planning significantly streamlines the assembly and finishing stages.

Post-Printing Assembly and Finishing

Once your large 3D model has been successfully split and printed in smaller, manageable parts, the next crucial step is to bring them together seamlessly. This phase transforms individual pieces into a cohesive whole, requiring careful attention to detail to achieve a professional and aesthetically pleasing result. Effective assembly and finishing techniques are key to showcasing the full potential of your segmented print.The process of assembling and finishing split 3D printed parts involves several stages, each contributing to the final quality of the model.

From the initial joining of pieces to the final touches of sanding and painting, every step plays a vital role in creating a durable and visually impressive object. Understanding the best methods for each stage will ensure your large-scale prints look as good as they are structurally sound.

Joining Split 3D Printed Parts

Various methods are available for securely connecting the individual components of your large 3D print. The choice of adhesive or joining technique often depends on the material of your prints, the size of the parts, and the desired strength of the bond. Experimentation may be necessary to find the most suitable method for your specific project.Common joining methods include:

- Super Glue (Cyanoacrylate): This is a fast-acting adhesive suitable for most common 3D printing plastics like PLA and ABS. It creates a strong bond quickly but can be brittle and may leave visible seams if not applied carefully. For larger parts, it’s often used in conjunction with other methods for structural support.

- Epoxy Resin: A two-part adhesive that forms a very strong and durable bond. Epoxy is excellent for filling small gaps and can provide a more flexible connection than super glue, making it ideal for parts that might experience stress. It requires mixing and has a longer curing time.

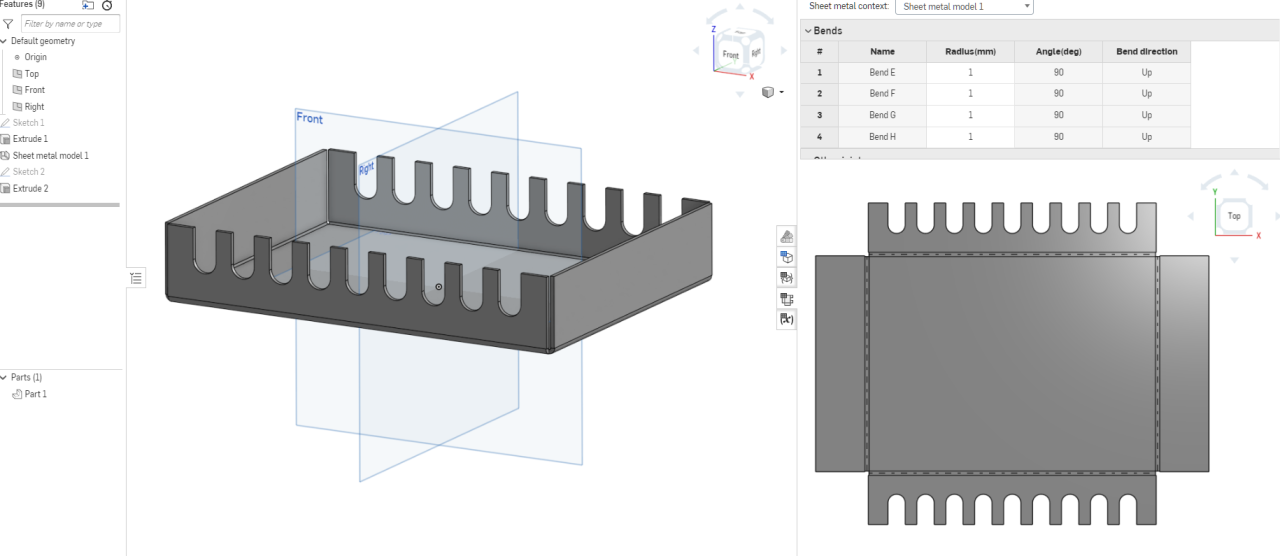

- Plastic Welding: This technique involves melting the plastic of the parts together, often using a specialized soldering iron with a plastic welding tip or a dedicated plastic welder. It’s particularly effective for ABS and can create incredibly strong, seamless joints, almost as if the parts were printed as one. Filler rods made of the same plastic are often used to reinforce the weld.

- Mechanical Fasteners: For very large or heavy models, or those that might need to be disassembled, using screws, bolts, or pins can be an effective joining method. These are often combined with adhesives for added strength. Recesses for nuts and bolts can be designed into the model during the splitting phase.

- Friction Welding: While less common for hobbyists, friction welding uses mechanical friction to generate heat and melt the plastic surfaces together. This can create very strong bonds but requires specialized equipment.

Achieving Seamless Transitions Between Assembled Pieces

Creating a smooth, continuous surface across the joins of your assembled model is essential for a professional finish. This often involves careful preparation and the use of fillers to disguise or eliminate the visible seams. Patience and meticulous application are key to achieving this smooth transition.Techniques for seamless transitions include:

- Precise Alignment: Before applying any adhesive, ensure the parts fit together perfectly. Small adjustments or minor sanding of the mating surfaces can significantly improve the fit and reduce the need for extensive filling later.

- Gap Filling: Small gaps between parts can be filled with various materials. For plastic models, specialized plastic putty or filler designed for 3D prints is ideal. Alternatively, a mixture of fine sawdust and wood glue (for some materials), or even a thick mixture of super glue with talcum powder or baking soda, can be used to create a quick-drying filler.

- Sanding and Smoothing: Once the filler has cured, the area needs to be carefully sanded. Start with a coarser grit sandpaper to level the filler with the surrounding plastic and then progressively move to finer grits to achieve a smooth finish.

- Scribing or Rescribing Lines: If the original model had panel lines or details that were interrupted by the split, these can be recreated using a hobby knife, scribing tool, or even a heated needle after assembly and filling.

Sanding, Filling, and Painting Split Models

The post-assembly stage of sanding, filling, and painting is where individual parts truly become a unified whole. These steps are critical for hiding print lines, smoothing out imperfections, and preparing the model for a durable and attractive paint job. Each step requires a methodical approach for optimal results.A detailed approach to finishing:

- Sanding: Begin sanding the entire assembled model, not just the seams. Start with a medium grit sandpaper (e.g., 220-grit) to remove any rough spots or support material residue. Progress to finer grits (e.g., 400, 600, 800, and even higher) to create a smooth surface. Wet sanding with water can help reduce dust and prevent clogging of the sandpaper, especially with finer grits.

- Filling: Use a good quality filler to address any remaining gaps, pinholes, or layer lines that sanding hasn’t completely removed. Apply filler thinly and evenly. For larger imperfections, multiple thin applications may be better than one thick coat. Allow each layer to dry completely before sanding.

- Priming: A primer acts as a base coat that adheres well to the plastic and provides a uniform surface for paint. It also highlights any imperfections that may have been missed during filling and sanding. Apply thin, even coats of primer. After priming, inspect the model again and perform any necessary touch-ups with filler and re-prime.

- Painting: Once the primer is dry and the surface is smooth, you can begin painting. Airbrushing offers the most control for smooth, even coats. Brush painting can also be effective, but requires more skill to avoid visible brush strokes. Acrylic paints are a popular choice for 3D prints due to their versatility and ease of cleanup. Consider using multiple thin coats rather than one thick coat to achieve the best coverage and finish.

- Sealing: After the paint has fully cured, apply a clear coat (matte, satin, or gloss, depending on the desired finish) to protect the paint job and provide a uniform sheen.

Reinforcing Joints for Increased Durability

For models that will be handled frequently, displayed in high-traffic areas, or are particularly large and heavy, reinforcing the joints is essential for long-term durability. This can involve internal supports, external bracing, or specific adhesive techniques that enhance structural integrity.Methods for reinforcing joints:

- Internal Dowels or Rods: Design or create small holes in the mating surfaces of the split parts that align when joined. Insert wooden dowels, metal rods, or even thick filament pieces into these holes, securing them with adhesive. This provides significant internal support to the joint.

- Reinforcing Plates or Gussets: Small pieces of plastic, metal, or even strong cardboard can be glued across the inside of a joint to act as a brace. For external reinforcement, small triangular gussets can be added to corners or edges where parts meet.

- Filament Welding with a Soldering Iron: As mentioned in joining methods, plastic welding can be a powerful reinforcement technique. By adding extra filament material to the seam and melting it into the joint, you create a much stronger bond that is integral to the plastic itself.

- Using Stronger Adhesives in Key Areas: While super glue might be used for initial tacking, reinforcing critical stress points with a stronger epoxy or a plastic welding technique will significantly increase the model’s resilience.

- Designing for Interlocking Features: During the splitting process, consider designing interlocking tabs and slots that fit together before the primary adhesive is applied. These mechanical connections add considerable strength to the joint.

The strength of a segmented model lies not just in the individual parts, but in the integrity of the connections between them.

Advanced Splitting Considerations

As we delve deeper into the art of model splitting, we encounter scenarios that require more nuanced approaches. These often involve models with inherent complexities, such as internal cavities, intricate interlocking mechanisms, or the specific requirement for articulated movement post-assembly. Addressing these challenges effectively ensures a successful and functional final print.This section focuses on advanced techniques and strategies that go beyond simple planar cuts, offering solutions for the more demanding aspects of large model segmentation.

Splitting Models with Internal Structures or Complex Geometries

Models featuring internal voids, hollow sections, or intricate, non-manifold geometries present unique splitting challenges. A common strategy is to leverage these internal features to your advantage by strategically placing cuts that either follow natural breaks or create accessible sections for easier printing and assembly. For models with complex organic shapes or fine details, it is often beneficial to perform cuts that minimize the need for extensive support structures within the internal cavities, as these can be difficult to remove and may damage delicate features.When dealing with complex geometries, consider the following:

- Exploiting Natural Divisions: Identify areas where the model naturally breaks down, such as between limbs, distinct components, or along panel lines. These areas often require less modification for a clean split.

- Creating Access Points: For models with enclosed internal spaces, consider splitting them in a way that allows for easier access to the interior for potential painting or the addition of internal components. This might involve creating a removable section or splitting the model into layers.

- Minimizing Internal Supports: Analyze the slicing software’s support generation for internal voids. If possible, orient the split parts or adjust the cut to reduce the need for supports inside the model, which can be problematic to remove.

- Using Boolean Operations: Advanced modeling software allows for the use of boolean operations (union, difference, intersection) which can be instrumental in cleanly separating complex intersecting geometries or hollowing out sections for easier printing.

The Role of Support Structures in Split Parts

Support structures are indispensable when printing 3D models, and this holds true, perhaps even more so, for split parts. The act of splitting a model often introduces new overhangs and exposed internal surfaces that would not exist in the original monolithic form. Proper consideration of support structures is crucial for the integrity and successful printing of each individual segment.The effective use of support structures for split parts involves:

- Anticipating Overhangs: Each split surface can introduce new overhangs. Analyze each part individually in your slicer software to identify all areas that will require support.

- Minimizing Support Contact Points: For parts that will be visible, aim to orient them in the slicer to minimize the contact points of supports on critical surfaces. This reduces post-processing effort and preserves surface detail.

- Internal vs. External Supports: Be mindful of supports generated within cavities or on internal mating surfaces. These can be particularly challenging to remove and may require specialized tools or techniques. Sometimes, strategically splitting a model can help avoid internal supports altogether.

- Support Material Choice: If your printer supports dual extrusion, consider using a dissolvable support material for complex internal structures or delicate mating surfaces. This can greatly simplify the removal process.

Dealing with Interlocking Parts for Separate Printing

Designing models with interlocking parts, such as puzzle joints or snap-fit connectors, requires careful planning when splitting. The goal is to ensure that each interlocking feature prints accurately and that the tolerances are maintained for a secure and seamless assembly. This often involves creating slightly larger or smaller features depending on the printing technology and material used to account for shrinkage or expansion.Methods for handling interlocking parts include:

- Tolerancing: This is paramount. For parts that are designed to fit snugly, you will need to introduce a slight gap (tolerance) between the interlocking features. This gap accounts for the printer’s accuracy and material properties. For example, if two parts are meant to slot together, you might add a 0.1mm gap to each side of the slot.

- Chamfering and Filleting: Adding small chamfers (angled edges) or fillets (rounded edges) to the leading edges of interlocking components can significantly ease assembly. These features guide the parts into place and prevent them from snagging.

- Keying and Alignment Features: Incorporate small protrusions or indentations (keys and slots) on the interlocking surfaces. These not only help with alignment but also provide a more robust connection.

- Print Orientation Testing: It is often advisable to print a small test piece of the interlocking mechanism before committing to printing the entire model. This allows you to verify your tolerances and adjust them if necessary.

Workflow for Splitting Models for Articulation or Movement

Creating models with articulated joints or moving parts requires a specialized splitting workflow. The key is to design the model with the intended movement in mind from the outset, ensuring that the split lines facilitate the creation of functional joints rather than just structural separation. This often involves creating separate components for each moving part and designing them to connect in a way that allows for rotation, bending, or sliding.A workflow for splitting models for articulation typically involves:

- Joint Design Integration: Before splitting, integrate the joint mechanisms into the original model. This could be as simple as designing pegs and holes for basic articulation or more complex ball-and-socket joints.

- Strategic Split Placement: Place split lines adjacent to or within the joint mechanism itself. The goal is to separate the components that will form the joint, allowing them to move independently. For instance, a knee joint might be split into thigh and calf sections, with a separate peg or pin designed to pass through both.

- Designing for Assembly and Movement: Ensure that the split parts can be easily assembled to form the joint and that the joint itself allows for the desired range of motion. This might involve adding internal cavities for springs or other actuation mechanisms.

- Tolerance for Movement: Just as with interlocking parts, tolerances are critical. Ensure there is enough clearance around moving parts to prevent them from binding. For example, a rotating peg within a hole needs a small gap on all sides.

- Consideration of Printing Orientation for Joints: The orientation of each split part during printing can significantly impact the strength and functionality of the joint. For example, a peg printed horizontally might be stronger than one printed vertically.

Summary

Successfully splitting, printing, and assembling large 3D models transforms daunting projects into achievable realities. By leveraging the right software, employing strategic splitting techniques, and paying close attention to print preparation and post-processing, you can overcome the limitations of your printer and achieve professional-quality results. This comprehensive approach empowers you to tackle increasingly complex and larger-than-life creations, pushing the boundaries of what’s possible in your 3D printing endeavors.