How to Print Functional Replacement Parts for a Drawer introduces a comprehensive guide designed to empower individuals with the knowledge and skills to create essential components for their furniture. This exploration delves into the practical application of 3D printing technology for repairing and enhancing everyday items, offering a sustainable and cost-effective solution for common household issues.

We will navigate the intricacies of identifying the need for replacement parts, understanding the best materials and design principles for 3D printing, and mastering the technical aspects of preparation, printing, and post-processing. From initial measurements to final installation, this guide ensures that your printed parts are not only functional but also durable and aesthetically pleasing, bringing new life to your drawers.

Understanding Drawer Replacement Part Needs

When a drawer fails to function as intended, it often points to a damaged or missing component. Identifying these specific needs is the crucial first step in ensuring a successful repair or replacement. This section will delve into the common scenarios leading to part failures, the types of parts most frequently requiring replacement, and the essential information needed for accurate sourcing.The necessity for drawer replacement parts arises from a variety of factors, ranging from everyday wear and tear to accidental damage.

Understanding these underlying causes helps in selecting the most appropriate replacement and, in some cases, in preventing future issues.

Common Reasons for Drawer Part Failure

Drawer components are subjected to constant stress and movement, making them susceptible to wear and breakage. Common reasons for their failure include:

- Wear and Tear: Over time, the repeated sliding action can wear down runners, wheels, and guides, leading to stiff movement or complete failure.

- Impact and Stress: Dropping heavy items into a drawer, or slamming it shut forcefully, can crack or break plastic components, bend metal slides, or dislodge fasteners.

- Moisture Damage: In humid environments or due to spills, wooden drawer parts can swell, warp, or rot, compromising their structural integrity and fit.

- Manufacturing Defects: Occasionally, parts may fail prematurely due to inherent flaws in their design or materials used during production.

- Improper Installation: If drawer slides or other components were not installed correctly, they can experience uneven stress, leading to premature failure.

Frequently Replaced Drawer Parts

Certain drawer parts are more prone to failure due to their function and exposure to stress. Identifying these common culprits is key to efficient repair.

- Drawer Slides/Runners: These are perhaps the most commonly replaced parts. They guide the drawer’s movement and can become bent, broken, or have worn-out bearings.

- Drawer Handles and Knobs: These are frequently used and can become loose, stripped, or broken from impact or repeated use.

- Drawer Bottoms: The thin material forming the base of the drawer can sag, crack, or break, especially if overloaded or exposed to moisture.

- Drawer Glides and Wheels: Small wheels or plastic glides attached to the drawer or cabinet can break or wear down, causing the drawer to stick or scrape.

- Drawer Front Fascia: The decorative front panel of the drawer can become detached, cracked, or chipped.

- Drawer Box Components: The sides, back, or front of the drawer box itself can crack or separate, particularly at the joints.

Critical Information for Sourcing Replacement Parts

Before embarking on the task of finding or creating a replacement part, gathering precise information is paramount. This ensures compatibility and functionality, saving time and potential frustration.

- Part Type and Function: Clearly identify the specific part that needs replacing and its role in the drawer’s operation. For instance, is it a slide, a handle, a glide, or a structural piece?

- Material: Note the material of the original part (e.g., metal, plastic, wood). This is important for durability, aesthetics, and compatibility.

- Dimensions: Precise measurements are absolutely critical. This includes length, width, height, depth, and the spacing of any mounting holes or attachment points.

- Brand and Model (if applicable): If the drawer is part of a larger furniture piece or appliance, knowing the brand and model number can greatly assist in finding original or compatible parts.

- Mounting Mechanism: Understand how the part attaches to the drawer or cabinet. This could involve screws, clips, dowels, or specific interlocking mechanisms.

- Color and Finish: For visible parts like handles or drawer fronts, matching the original color and finish ensures a cohesive look.

Importance of Accurate Measurements for Functional Parts

For any part that directly influences the movement or structural integrity of the drawer, accurate measurements are not just important – they are indispensable. A slight deviation can render a replacement part useless or even cause further damage.

Accurate measurement is the bedrock of a successful functional replacement part. Without it, even the best intentions can lead to a poorly fitting or non-operational component.

When measuring for parts like drawer slides, consider the following:

- Length of the Slide: Measure the total length of the slide, both the cabinet member and the drawer member, if they are separable.

- Extension: Note whether the slide is a full-extension, partial-extension, or over-travel slide, as this affects its design and length.

- Mounting Hole Spacing: Measure the distance between the centers of mounting holes on both the cabinet and drawer sides of the slide.

- Width and Height: Measure the overall width and height of the slide profile.

- Gap: For runners and glides, measure the clearance needed between the drawer and the cabinet for smooth operation.

For other functional parts like drawer box joints or structural braces, precise measurements ensure that the new part will integrate seamlessly with the existing components, maintaining the drawer’s stability and operational efficiency. Even for smaller parts like wheels or bearings, precise diameter and width are crucial for proper engagement with their tracks.

Materials for 3D Printing Drawer Parts

Selecting the right filament is paramount when 3D printing functional replacement parts for drawers. The material’s properties directly influence the durability, strength, and longevity of the printed component, ensuring it can withstand the stresses of regular use. This section delves into the most suitable filament types, their comparative characteristics, and how to choose the best option for your specific drawer repair needs.

Designing and Modeling Replacement Parts

Designing and modeling functional replacement parts for drawers is a critical step that bridges the gap between understanding your needs and bringing a physical solution to life. This phase involves translating real-world measurements and requirements into precise digital blueprints that a 3D printer can interpret. A well-designed part not only replicates the original’s form but also ensures its intended function is restored or even improved.The fundamental principle guiding the design of a functional replacement part is to accurately capture the essential geometry and tolerances of the original component.

This means understanding how the part interacts with its surroundings and the forces it will experience. Key considerations include dimensions, clearances, mounting points, and material properties. The goal is to create a digital model that, when 3D printed, will seamlessly integrate into the drawer system and perform its task reliably.

Measuring Existing Parts or Drawer Components

Accurate measurements are the bedrock of successful 3D model creation for replacement parts. Without precise data, even the most sophisticated modeling software will produce a part that doesn’t fit or function correctly. This process requires a systematic approach to capture all relevant dimensions.Before beginning to measure, it is advisable to clean the existing part or drawer component thoroughly. Dust, grime, or old lubricant can obscure critical edges and surfaces.

For broken parts, carefully reassemble them as best as possible to get accurate measurements of the original, intact dimensions.Here are the essential tools and techniques for measuring:

- Digital Calipers: These are indispensable for measuring external dimensions, internal diameters, and thicknesses with high precision (typically to 0.01mm or 0.001 inches). They are ideal for measuring the width, height, and depth of brackets, the diameter of screw holes, and the thickness of plastic components.

- Rulers and Measuring Tapes: Useful for larger dimensions or when calipers are not suitable. Ensure they have clear markings for accurate readings.

- Protractor or Angle Finder: Important for capturing any angled features or clearances.

- Templates and Gauges: For standardized features like screw thread sizes or common hole diameters, pre-made gauges can save time and ensure accuracy.

- Photography: Taking detailed, well-lit photographs from multiple angles can serve as a visual reference and help identify features that might be difficult to measure directly. Using a ruler in the background of the photos can also provide a scale.

When measuring, focus on critical dimensions that define the part’s fit and function. This includes:

- Overall length, width, and height.

- Diameters of holes and shafts.

- Thickness of walls and flanges.

- Distances between mounting points or key features.

- Angles of any chamfers, fillets, or bevels.

It is often beneficial to measure a component multiple times to ensure consistency and accuracy. Documenting these measurements clearly, perhaps with a sketch, is crucial.

Using 3D Modeling Software to Create Precise Digital Models

Once measurements are meticulously gathered, the next step is to translate this data into a 3D digital model using specialized software. The choice of software ranges from beginner-friendly programs to professional-grade CAD (Computer-Aided Design) suites, depending on complexity and user expertise. The core principle here is to build the digital representation of the part by extruding, revolving, cutting, and combining basic geometric shapes based on the collected measurements.The process generally involves creating 2D sketches of the part’s profiles and then using these sketches to generate 3D features.

For instance, a drawer handle might start with a 2D sketch of its cross-section, which is then extruded along its length to create the 3D form. Holes are typically created by sketching their profiles and then using a “cut” or “extrude cut” operation.Key techniques employed in 3D modeling software include:

- Sketching: Creating 2D shapes (lines, arcs, circles, rectangles) that form the basis of 3D features. Dimensions are applied to these sketches to ensure accuracy.

- Extrusion: Extending a 2D sketch into a 3D object by a specified distance. This is common for creating straight components like drawer slides or simple handles.

- Revolution: Rotating a 2D sketch around an axis to create cylindrical or conical shapes. Useful for knobs or rounded components.

- Boolean Operations: Combining or subtracting shapes from each other to create complex geometries. For example, subtracting a cylinder from a cube to create a hole.

- Filleting and Chamfering: Rounding sharp edges (fillets) or beveling them (chamfers) to improve aesthetics, reduce stress concentrations, or aid in assembly.

- Shelling: Creating hollow parts with a uniform wall thickness, which can save material and print time.

It is important to pay close attention to tolerances. For parts that need to fit snugly, like drawer slides, ensure that the dimensions in the model account for the manufacturing tolerances of both the printed part and the mating components. Adding small clearances (e.g., 0.1-0.3mm) can often prevent parts from binding or being too loose.

Designing a Simple Drawer Slide or Handle

Let’s consider designing a simple replacement drawer slide component, focusing on critical dimensions. Imagine a basic L-shaped bracket that attaches to the side of the drawer and engages with a track on the cabinet.For this example, we’ll assume the original slide has the following critical dimensions (measured with digital calipers):

- Length of the vertical leg: 50 mm

- Length of the horizontal leg: 30 mm

- Thickness of both legs: 3 mm

- Width of the entire slide profile: 15 mm

- Hole diameter for mounting screws: 4.5 mm

- Distance from the end of the vertical leg to the center of the first screw hole: 10 mm

- Distance between the centers of two screw holes (if multiple): 25 mm

Using 3D modeling software, the process would involve:

- Create a 2D sketch of the L-shape profile. This would consist of two perpendicular rectangles, each with a thickness of 3 mm. The total height of the vertical leg would be 50 mm, and the total depth of the horizontal leg would be 30 mm.

- Extrude this 2D profile by the width of the slide, which is 15 mm. This creates the basic 3D form of the drawer slide.

- Add mounting holes. Sketch a circle with a diameter of 4.5 mm at the specified locations on the vertical leg (e.g., 10 mm from the end, and 25 mm from the first hole if a second is needed). Use the “extrude cut” feature to create the holes through the thickness of the leg.

- Consider adding a small fillet to the inside corner where the two legs meet. This can add strength and prevent stress concentration. A fillet radius of 2-3 mm would be appropriate.

For a drawer handle, the design would be simpler. If it’s a basic bar handle, you would sketch a profile (e.g., a rectangle or a rounded rectangle) and extrude it to the desired length. Then, you would add mounting holes on the ends or the back, ensuring the distance between hole centers matches the drawer front’s pre-drilled holes.

Creating a Digital Model of a Broken Drawer Knob

Replacing a broken drawer knob is a common task, and modeling one from scratch can be straightforward, even if the original is damaged. The key is to identify the core shape and the attachment mechanism.Let’s assume a simple, spherical drawer knob with a threaded post that screws into the knob. The knob itself is broken, but we can still measure its intact features and infer the original dimensions.Here is a step-by-step procedure for creating a digital model of a broken drawer knob:

- Assess the Damage and Identify Key Features: Examine the broken knob. Determine its original shape (spherical, cylindrical, faceted, etc.) and its approximate size. Note the location and type of the broken connection point (e.g., a threaded insert, a shaft that snapped off).

- Measure the Intact Portion: Use digital calipers to measure the diameter of the intact part of the knob. If it’s spherical, measure the diameter. If it has a specific profile, measure the key dimensions of that profile.

- Measure the Attachment Mechanism: If the threaded post or a part of it remains attached to the drawer front, measure its diameter and the pitch of the threads (threads per inch or millimeters per thread). If the post is broken off inside the knob, you may need to estimate or measure the diameter of the hole left behind and assume a standard thread size (e.g., M4, M5).

- Measure the Mounting Hole in the Drawer Front: If you are replacing the knob entirely and not just the broken insert, measure the diameter of the hole in the drawer front where the knob attaches.

- Open 3D Modeling Software: Launch your preferred CAD software.

- Model the Knob Body:

- If the knob is spherical, create a sphere with the measured diameter.

- If it has a different profile, sketch the 2D profile (e.g., a rounded rectangle for a more ergonomic handle) and extrude or revolve it to create the 3D shape.

- Model the Attachment Feature:

- For a threaded post: Create a cylinder with the diameter of the post. Then, use the software’s thread modeling tools (if available) or manually create a helical cut to represent the threads. Ensure the thread pitch matches your measurements or the standard you’ve chosen.

- For a simple shaft or hole: Create a cylinder with the appropriate diameter for the shaft or the diameter of the hole for the shaft to pass through.

- Combine and Refine: If the attachment feature is separate (like a metal insert), model it as a separate part and then position it correctly within the knob body. If it’s integrated, use Boolean operations to merge the features. Add fillets or chamfers to smooth edges and improve ergonomics or strength.

- Add Design Modifications (Optional): Consider making the replacement knob slightly larger or with a more comfortable grip if the original was awkward.

- Export the Model: Save your design as an STL or 3MF file, which are standard formats for 3D printing.

For example, if you measure a broken spherical knob with a diameter of 30 mm and the broken attachment point reveals a hole suitable for an M5 screw (5mm diameter), you would create a sphere of 30mm diameter and then use a cut operation to create a central cylindrical hole of 5mm diameter, extending deep enough to accommodate the screw length.

If a thread is needed, you would add an M5 thread to this hole.

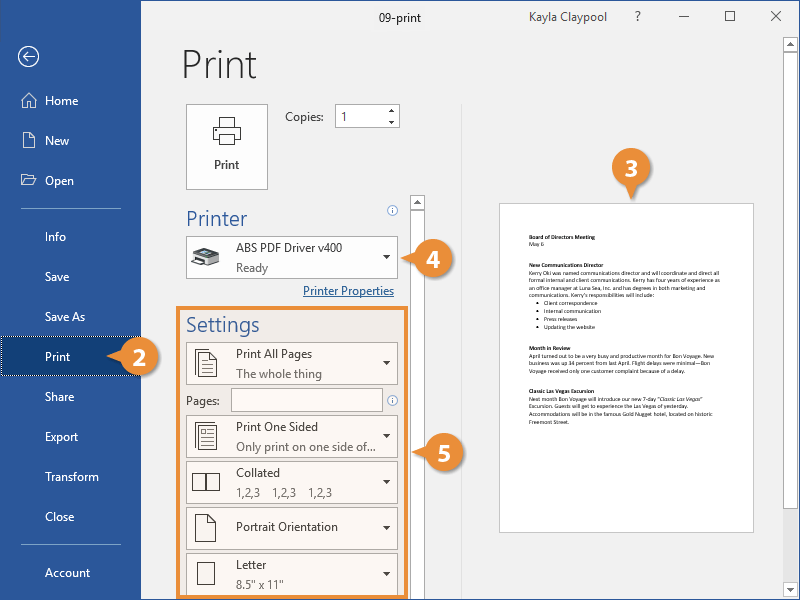

Preparing Models for Printing

Once your drawer replacement part has been designed and modeled, the next crucial step is to prepare it for the 3D printer. This involves translating your digital design into a language the printer understands, ensuring the final print is strong, accurate, and fits perfectly. This process is handled by a software called a slicer, which plays a vital role in determining the success of your print.The slicing process takes your 3D model (typically in an STL or 3MF file format) and divides it into hundreds or thousands of thin horizontal layers.

For each layer, the slicer generates a series of toolpaths that the 3D printer’s nozzle will follow to deposit material. The quality and characteristics of the final print are heavily influenced by the settings chosen within the slicer software.

Slicer Settings for Strength and Fit

Understanding and configuring key slicer settings is paramount to achieving robust and precisely fitting replacement parts. These settings directly impact how the material is deposited, how layers adhere to each other, and the overall dimensional accuracy of the print. Careful adjustment here can mean the difference between a functional part and a failure.Here are some of the most critical slicer settings to consider:

- Layer Height: This setting determines the thickness of each individual layer. Smaller layer heights (e.g., 0.1mm) result in smoother surfaces and finer detail but increase print time. Larger layer heights (e.g., 0.2mm or 0.3mm) print faster but may show more visible layer lines and have slightly reduced strength. For functional parts, a balance is often sought, with 0.15mm to 0.2mm being a common range.

- Wall Thickness/Perimeters: This refers to the number of solid outer shells printed around the part. Increasing the number of perimeters significantly enhances the part’s strength and durability, especially against lateral forces. For drawer parts that will experience stress, using 3-5 perimeters is often recommended.

- Infill Density and Pattern: Infill is the internal structure printed within the part to provide support and reduce material usage. Higher infill densities (e.g., 20-50% or more) lead to stronger parts. The infill pattern also matters; common patterns like grid, gyroid, or cubic offer good strength in multiple directions. For critical structural components, a higher density with a robust pattern is advisable.

- Print Speed: While faster printing is tempting, excessively high speeds can compromise layer adhesion and overall part quality. For functional parts, it’s often better to print slightly slower to ensure good material flow and bonding between layers.

- Temperature (Nozzle and Bed): Correct printing temperatures for your chosen filament are essential for proper layer adhesion. Consult the filament manufacturer’s recommendations. Consistent temperatures prevent warping and delamination, which are critical for part integrity.

- Retraction Settings: Proper retraction settings minimize stringing and blobs, which can affect the dimensional accuracy and surface finish of your part. This is important for ensuring parts fit snugly into their intended slots.

Part Orientation for Durability

The way a 3D model is oriented on the print bed has a profound impact on the strength of the final part. 3D prints are inherently anisotropic, meaning their strength varies depending on the direction of the applied force relative to the printed layers.

For maximum durability, orient parts so that the primary stresses they will experience are aligned with the direction of layer adhesion, not perpendicular to it.

This principle is often best illustrated with an example: imagine a hook designed to hold a drawer. If printed standing upright, the layers would be horizontal, and a downward force on the hook would pull the layers apart, leading to delamination and failure. If printed lying on its side, with the hook’s curve facing upwards, the force would be applied along the layers, making it much stronger.Consider these best practices for orienting parts on the print bed:

- Minimize overhangs: Orient parts to reduce the need for support material, as supports can sometimes leave rough surfaces or weaken areas where they attach.

- Align layers with stress: As mentioned, ensure the strongest axis of the part aligns with the expected direction of force.

- Maximize bed adhesion: Ensure a large, flat surface area of the part is in contact with the print bed to prevent warping and detachment during printing.

- Consider print time: While durability is key, sometimes a slight compromise in orientation might be acceptable if it drastically reduces print time without severely compromising strength.

Supports and Infill for Structural Integrity

The internal structure (infill) and any necessary external structures (supports) are critical for the structural integrity of printed replacement parts. They provide the necessary backbone for the printed object and ensure it maintains its shape during and after printing.Infill provides internal scaffolding. A higher infill density means more material is used internally, creating a denser, stronger part. Different infill patterns distribute stress in unique ways.

For example, a gyroid infill is known for its excellent strength in all directions.Supports are temporary structures printed to hold up overhangs or bridges in your model that would otherwise collapse during printing.

- When to use supports: Supports are necessary for any part that has overhangs greater than approximately 45 degrees or bridges longer than a few millimeters. Carefully consider if supports are truly needed, as their removal can sometimes damage the part.

- Support settings: Slicer software offers various support settings, including the density, pattern, and contact distance between the support and the model. Fine-tuning these can make support removal easier and cleaner. A common strategy is to use a sparse infill for supports with a pattern that is easy to break away.

- Infill strategies: For drawer parts, consider these infill strategies:

- High density (30-50% or more): For parts that will bear significant weight or stress.

- Strong infill patterns: Gyroid, cubic, or 3D cubic are excellent choices for overall strength.

- Concentric infill: Can be useful for creating strong shells or rims.

Pre-Print Model Preparation Checklist

Before sending your model to the slicer, a final review and preparation are essential to avoid common printing pitfalls. This checklist ensures you’ve considered all critical aspects of your digital model.

- File Format Verification: Ensure your model is saved in a compatible format (e.g., STL, 3MF, OBJ).

- Watertight Model Check: Confirm that your 3D model is “watertight,” meaning it has no holes or non-manifold geometry that could confuse the slicer. Most CAD software has tools for this.

- Dimensional Accuracy Review: Double-check that the dimensions of your model match the original part or your design specifications.

- Scale Check: Ensure the model is at the correct scale in your CAD software before exporting.

- Orientation on Build Plate: Decide on the optimal orientation for strength and minimal supports.

- Support Strategy Defined: Determine if supports are needed and plan the type and density.

- Infill Strategy Selected: Choose an appropriate infill density and pattern for the intended use.

- Layer Height and Wall Thickness Considered: Select settings that balance detail, print time, and strength.

- Test Print (Optional but Recommended): For critical parts, consider printing a small section or a scaled-down version to test fit and strength before committing to a full print.

- File Naming Convention: Use a clear and descriptive file name for easy identification.

3D Printing Techniques and Considerations

Successfully printing functional replacement parts for drawers involves selecting the right 3D printing technology and carefully managing printing parameters. This section delves into the common technologies, essential settings, and troubleshooting steps to ensure your printed parts are robust and reliable.

Common 3D Printing Technologies for Functional Parts

Several 3D printing technologies are well-suited for creating durable and functional drawer replacement parts. The choice often depends on the required strength, detail, and material properties.

- Fused Deposition Modeling (FDM): This is the most common and accessible 3D printing technology. It works by extruding thermoplastic filament layer by layer. FDM is excellent for creating parts with good mechanical strength, making it ideal for drawer runners, handles, and brackets. The variety of available filament materials, such as ABS, PETG, and Nylon, allows for tailoring part properties to specific needs.

- Stereolithography (SLA) / Digital Light Processing (DLP): These technologies use UV light to cure liquid photopolymer resin layer by layer. SLA/DLP printers can achieve very high detail and smooth surface finishes, which can be beneficial for aesthetically pleasing parts or components requiring tight tolerances. However, resin parts can sometimes be more brittle than FDM prints, and post-curing is necessary to achieve full strength.

- Selective Laser Sintering (SLS): SLS printers use a laser to fuse powdered materials, typically nylon. This technology produces parts with excellent mechanical properties, high strength, and good chemical resistance without the need for support structures. SLS is a professional-grade technology often used for end-use functional parts, though it is generally more expensive and less accessible than FDM.

Typical Printing Parameters and Their Impact

The settings used during the 3D printing process significantly influence the strength, accuracy, and overall quality of the printed part. Understanding these parameters is crucial for achieving functional results.

Key Printing Parameters:

- Layer Height: This determines the thickness of each printed layer. A smaller layer height (e.g., 0.1mm) results in higher detail and a smoother surface finish but increases print time. A larger layer height (e.g., 0.2mm or 0.3mm) prints faster but can lead to more visible layer lines and potentially reduced strength in certain orientations. For functional parts, a balance is often struck to ensure adequate strength without excessive print times.

- Infill Density and Pattern: Infill refers to the internal structure of the printed part. Higher infill density (e.g., 50-100%) leads to stronger, heavier, and more rigid parts. Lower infill density (e.g., 15-30%) saves material and reduces print time but results in weaker parts. Common infill patterns include grid, cubic, gyroid, and honeycomb, each offering different strength characteristics. For functional drawer parts, a density of 50% or higher is often recommended, with patterns like gyroid or cubic providing good all-around strength.

- Print Speed: The speed at which the print head moves affects print quality and time. Printing too fast can lead to under-extrusion, poor layer adhesion, and decreased accuracy. Printing too slowly can increase print time unnecessarily. Optimal print speeds are typically found through calibration and depend on the printer, material, and specific part geometry.

- Printing Temperature (Nozzle and Bed): The correct nozzle temperature is critical for proper filament melting and extrusion, ensuring good layer adhesion. The bed temperature is essential for preventing warping and ensuring the first layer adheres well to the print surface. These temperatures are material-specific and must be set according to the filament manufacturer’s recommendations.

- Retraction Settings: Retraction is the process of pulling filament back into the nozzle when the print head moves between sections. Properly configured retraction prevents stringing and oozing, leading to cleaner prints.

Troubleshooting Common Printing Issues Affecting Functionality

Even with careful preparation, printing issues can arise that compromise the functionality of your drawer parts. Identifying and resolving these problems quickly is key to a successful print.

Common Issues and Solutions:

- Warping: This occurs when the corners of the print lift off the print bed. It is often caused by uneven cooling and material shrinkage.

- Solutions: Ensure proper bed adhesion (see below), use a heated bed, employ a brim or raft, and consider printing in an enclosed environment to maintain stable temperatures.

- Layer Shifting: Layers are misaligned, creating visible steps or breaks in the print. This can be due to mechanical issues with the printer (loose belts, binding axes) or excessive print speed.

- Solutions: Check and tighten printer belts and pulleys, ensure axes move freely, and reduce print speed, especially for outer walls.

- Under-extrusion: Parts appear thin, weak, or have gaps due to insufficient filament being extruded.

- Solutions: Verify nozzle temperature, check for filament clogs, ensure the extruder gear is gripping the filament properly, and calibrate E-steps (extruder steps per millimeter).

- Stringing: Fine hairs of plastic connect different parts of the print, often seen when the print head travels.

- Solutions: Optimize retraction settings (distance and speed) and slightly reduce nozzle temperature.

The Importance of Bed Adhesion for Successful Print Outcomes

Bed adhesion refers to how well the first layer of the 3D print sticks to the build plate. Without adequate adhesion, prints are prone to warping, detaching from the bed mid-print, and ultimately failing.

For functional parts, a solid foundation provided by excellent bed adhesion is non-negotiable.

This ensures that the entire part is printed without disruptions, maintaining its intended dimensions and structural integrity. Common methods to improve bed adhesion include using a clean print surface (e.g., glass, PEI sheet), applying adhesion promoters like glue stick or hairspray, and ensuring the correct bed temperature for the material being used. For larger parts, a brim or raft can also significantly enhance adhesion by increasing the surface area in contact with the bed.

Elaborating on Layer Adhesion and Its Role in Part Strength

Layer adhesion is the bond formed between successive layers of extruded material during the printing process. For functional parts, strong layer adhesion is paramount, as it directly dictates the part’s overall strength and durability, particularly when subjected to stress.

The strength of a 3D printed part is often anisotropic, meaning it is stronger in some directions than others. Layer adhesion is the primary factor determining its strength along the Z-axis.

When layers do not bond properly, the part can delaminate or break along these weak interfaces, especially when forces are applied perpendicular to the layers. Factors influencing layer adhesion include:

- Printing Temperature: Ensuring the nozzle temperature is within the optimal range for the filament allows for sufficient melting and fusion between layers.

- Cooling Fan Speed: While cooling is necessary to solidify layers, excessive cooling, especially on the initial layers, can hinder proper bonding.

- Print Speed: Printing too quickly may not give the molten filament enough time to properly fuse with the layer below.

- Material Choice: Some materials, like ABS and Nylon, generally exhibit better layer adhesion than others, especially when printed at appropriate temperatures and with controlled cooling.

By carefully controlling these parameters, you can maximize the layer adhesion and, consequently, the functional strength of your 3D printed drawer replacement parts.

Post-Processing and Finishing

Once your drawer replacement part has been successfully printed, the journey doesn’t end there. Post-processing and finishing are crucial steps to transform a raw 3D print into a smooth, functional, and aesthetically pleasing component that seamlessly integrates with your existing furniture. This stage involves refining the surface, enhancing its durability, and ensuring it meets your specific functional and visual requirements.The objective of post-processing is to address any imperfections inherent in the 3D printing process, such as layer lines, support material remnants, and surface irregularities.

By carefully employing various techniques, you can achieve a professional-grade finish that not only looks good but also performs optimally as a replacement part.

Cleaning and Preparing 3D Printed Parts

After removing a 3D print from the build plate, it’s essential to clean it thoroughly. This initial cleaning removes any residual printing material, such as uncured resin for SLA/DLP prints or loose filament for FDM prints. It also prepares the surface for subsequent finishing steps.Here are common methods for cleaning and preparing your 3D printed parts:

- FDM Prints: For fused deposition modeling (FDM) prints, the primary cleaning involves removing any support structures. This can be done manually with pliers, flush cutters, or a hobby knife. For prints with soluble supports, the part can be submerged in a compatible solvent (e.g., water for PVA, d-limonene for HIPS) according to the manufacturer’s instructions. After support removal, a gentle wipe-down with isopropyl alcohol (IPA) can remove any oils or dust.

- SLA/DLP Prints: Stereolithography (SLA) and Digital Light Processing (DLP) prints require a more involved cleaning process due to the liquid resin. After printing, parts are typically washed in isopropyl alcohol (IPA) or a specialized resin cleaner to remove any uncured resin. This is often done in an ultrasonic cleaner or by agitating the part in a container of IPA. Ensure thorough rinsing to prevent sticky surfaces.

- General Cleaning: Regardless of the printing technology, a final rinse with water and mild soap can be beneficial, followed by complete air drying. For all print types, inspecting the part for any remaining debris or print artifacts is a crucial preparatory step.

Sanding, Filling, and Smoothing Surfaces

Achieving a smooth surface finish is paramount for both the aesthetic appeal and the functional performance of drawer replacement parts. Layer lines, a common characteristic of 3D printing, can be reduced or eliminated through careful sanding and filling.The process of refining the surface typically involves a progression of grits and the use of filling compounds.

- Sanding: Begin with a coarser grit sandpaper (e.g., 100-220 grit) to quickly remove prominent layer lines and imperfections. Gradually move to finer grits (e.g., 320, 400, 600, and even up to 2000 grit or higher for a mirror finish). Wet sanding, using water as a lubricant with finer grits, can help prevent clogging of the sandpaper and produce a smoother finish.

Always sand in a consistent direction or use circular motions, and ensure the part is clean between grit changes.

- Filling: For deeper imperfections or to fill significant layer lines, a filler material is often necessary. Common options include:

- Automotive Body Filler (Bondo): A two-part epoxy filler that is durable and sandable. It’s excellent for larger repairs or smoothing significant surface variations.

- Wood Filler: Suitable for some plastics, especially PLA, and can be easier to work with for smaller imperfections.

- 3D Printing Specific Fillers: Various manufacturers offer specialized fillers designed to adhere well to 3D printed materials.

Apply the filler sparingly, let it cure completely according to the product instructions, and then sand it down to match the surrounding surface. Repeat applications may be necessary for optimal results.

- Smoothing Compounds and Solvents: For certain plastics like ABS, vapor smoothing using acetone can create an incredibly smooth, almost injection-molded finish. This process involves exposing the printed part to acetone vapor, which slightly melts and smooths the surface. This technique requires extreme caution and proper ventilation due to the flammability and fumes of acetone. For PLA, less aggressive smoothing agents or specialized smoothing solutions may be available, though they are generally less effective than acetone for ABS.

Strengthening Printed Parts Through Post-Treatments

While 3D printing offers design freedom, some printed parts may benefit from additional strengthening to withstand the stresses of drawer operation. Post-treatment methods can enhance the mechanical properties of the printed material.Several techniques can be employed to increase the durability and resilience of your 3D printed components.

- Annealing: For thermoplastic filaments like PLA and PETG, annealing can improve their heat resistance and mechanical strength. This involves heating the printed part in an oven to a temperature below its melting point but above its glass transition temperature for a specific duration. For PLA, this is typically around 90-110°C (194-230°F) for 30 minutes to a few hours, depending on the desired outcome and the specific PLA blend.

It’s crucial to research the optimal annealing parameters for your specific filament, as improper annealing can lead to warping or degradation. Place the part on a non-stick surface like parchment paper or a silicone mat, and ensure it is not under any stress during the process.

- Epoxy Coating: Applying a thin layer of epoxy resin to the surface of a printed part can significantly increase its strength, rigidity, and resistance to wear and tear. This is particularly useful for parts that experience friction or impact. Ensure the part is clean and dry before application, and use a high-quality, clear epoxy that is compatible with your print material.

- Fiberglass or Carbon Fiber Reinforcement: For high-stress applications, it’s possible to embed fiberglass or carbon fiber cloth within layers of epoxy resin applied to the printed part. This creates a composite structure that is exceptionally strong and rigid.

Painting and Coating Printed Parts

To ensure your 3D printed drawer replacement parts blend seamlessly with your existing furniture, painting or coating them is often necessary. This not only enhances the aesthetics but can also provide an additional layer of protection.The choice of paint or coating depends on the material of your print and the desired finish.

- Priming: Before painting, applying a primer is essential for good adhesion and a uniform base color. Use a primer specifically designed for plastics or 3D printed materials. Several thin coats are generally better than one thick coat.

- Painting Techniques:

- Spray Paint: Aerosol spray paints offer a convenient way to achieve a smooth, even finish. Use light, sweeping motions and multiple thin coats to avoid drips and runs. Allow each coat to dry thoroughly before applying the next.

- Brush Painting: For smaller parts or intricate details, acrylic paints applied with a brush can be effective. Multiple thin layers are recommended.

- Airbrushing: An airbrush provides excellent control for achieving very smooth gradients and professional-looking finishes.

Consider using paints that are designed for plastic surfaces. For furniture-grade finishes, acrylic lacquers or enamels are often good choices.

- Clear Coats: After the color coat has dried, applying a clear coat (e.g., matte, satin, or gloss varnish) provides durability, protects the paint, and offers the desired sheen.

- Staining: For wood-like finishes, some filaments (e.g., wood-filled PLA) can be sanded and stained. However, the results can vary significantly depending on the filament composition.

Achieving a Smooth and Functional Surface Finish

The ultimate goal is to create a 3D printed drawer part that is both visually appealing and perfectly functional. This involves a systematic approach to surface finishing, paying attention to detail at each stage.A well-executed finishing process ensures the part slides smoothly, operates without snagging, and complements the overall aesthetic of the drawer.

- Iterative Refinement: Don’t expect perfection on the first attempt. Be prepared to repeat sanding, filling, or smoothing steps as needed.

- Focus on Functional Surfaces: Pay extra attention to surfaces that will be in contact with other parts or rails. These areas require the smoothest possible finish to minimize friction and wear.

- Test Fit Regularly: Throughout the finishing process, periodically test fit the part to ensure it is still within tolerance and operates smoothly. Adjustments may be needed as you build up layers of paint or coating.

- Consider Lubrication: For sliding parts, applying a dry lubricant like graphite powder or a silicone-based spray can further enhance smooth operation after the finishing is complete.

- Material Choice Impact: Remember that the base material of your print will influence the finishing options available and the ease with which a smooth finish can be achieved. Some materials are inherently easier to sand and finish than others.

Installing and Testing Replacement Parts

Having successfully designed, printed, and post-processed your drawer replacement part, the next crucial step is its integration and validation. This phase ensures that your 3D printed solution not only fits perfectly but also performs reliably under everyday use. Careful installation and thorough testing are key to achieving a durable and functional outcome.This section will guide you through the practical aspects of fitting your new part, assessing its performance, and troubleshooting any encountered issues, ultimately confirming its successful implementation.

Part Fitting and Installation Procedure

The successful installation of a 3D printed replacement part relies on a systematic approach to ensure it integrates seamlessly with the existing drawer mechanism. Before commencing, it is advisable to have the original part or a clear reference of its placement readily available.The general procedure involves the following steps:

- Preparation: Ensure the drawer and its runners are clean and free from debris. If the original part was damaged, carefully remove any remnants.

- Initial Placement: Gently attempt to fit the new part into its intended position. For components like drawer slides, runners, or handles, this might involve aligning them with pre-drilled holes or grooves.

- Securing the Part: If screws or other fasteners were used with the original part, use appropriate hardware to secure the 3D printed component. Be mindful of the torque applied to avoid damaging the printed material. For parts that snap or slide into place, ensure they are fully seated.

- Mechanism Integration: If the part is part of a moving mechanism, such as a drawer slide or a latch, test the movement manually. Ensure it slides smoothly and engages correctly without binding or excessive friction.

Functionality and Durability Testing Methods

Once the part is installed, it is essential to rigorously test its performance to confirm it meets the required functional and durability standards. This testing phase simulates real-world usage to identify potential weaknesses or areas for improvement.A comprehensive testing strategy includes:

- Smooth Operation Test: Repeatedly open and close the drawer several times. Observe the movement for any sticking, wobbling, or unusual noises. The action should be smooth and consistent, mirroring or exceeding the performance of the original part.

- Load Bearing Test: For parts that bear weight, such as drawer runners or internal supports, gradually add weight to the drawer. Observe how the part handles the load. For critical components, consider testing with a load slightly exceeding the expected maximum to assess its resilience.

- Stress and Strain Assessment: For parts subject to repetitive stress, like handles or drawer pulls, perform a series of vigorous pulls and pushes. This helps identify potential points of failure due to fatigue.

- Environmental Resistance Check: If the drawer is exposed to varying conditions (e.g., humidity, temperature fluctuations), consider how the material choice might affect long-term performance. While initial testing might not cover years of use, observing for immediate signs of warping or degradation is important.

Identifying and Addressing Fitting Issues and Performance Problems

Despite careful design and printing, minor discrepancies can sometimes arise, requiring attention to ensure optimal functionality. Proactive identification and resolution of these issues are key to a successful repair.Common issues and their solutions include:

- Tight Fit/Binding: If the part is too tight or causes the drawer to bind, it may indicate a slight dimensional inaccuracy. Gently sand down the contact points or, if the issue is significant, consider re-printing with minor adjustments to the model’s dimensions.

- Loose Fit/Wobbling: A loose part might require shims or a slightly thicker print. Alternatively, if fasteners are involved, consider using slightly larger screws or adding a thin layer of adhesive to secure the part more firmly.

- Sticking or Grinding: This often points to friction. Lubricating the contact surfaces with a suitable lubricant (e.g., silicone spray, graphite powder) can resolve this. If the issue persists, it might indicate a misalignment that needs correction in the design or installation.

- Weakness or Deformation Under Load: If the part shows signs of bending or cracking under load, it suggests the material might not be strong enough for the application, or the design lacks sufficient structural support. Reinforcing the design with thicker walls, fillets, or ribs, or selecting a stronger filament material, may be necessary.

Sequence of Checks for Intended Operation

To systematically verify that the replacement part is functioning precisely as intended, a structured sequence of checks is highly recommended. This ensures all aspects of its operation are evaluated.The following sequence of checks should be performed:

- Visual Inspection: Before any movement, visually confirm the part is correctly seated and aligned. Check for any obvious defects like cracks or warping.

- Manual Movement Test: Gently operate the drawer mechanism by hand. Listen for any unusual sounds and feel for smooth, consistent motion.

- Full Cycle Test: Operate the drawer through its full range of motion multiple times. Observe for any sticking points or areas of increased resistance.

- Load Application Test: If the part is load-bearing, apply a representative load and repeat the full cycle test.

- Fastener Security Check: If fasteners are used, re-check their tightness after the initial tests to ensure they have not loosened.

Iterative Testing and Refinement for Optimal Results

The process of 3D printing functional parts is often iterative. It is rare to achieve perfect results on the first attempt, especially for complex mechanisms. Embracing iterative testing and refinement is crucial for achieving the best possible outcome.This involves:

- Documenting Observations: Keep a record of any issues encountered during testing, including specific details about where and when they occurred.

- Analyzing Performance: Based on test results, analyze the root cause of any problems. This might involve comparing the printed part’s dimensions to the original or CAD model.

- Implementing Design Modifications: Make targeted adjustments to the 3D model based on the analysis. This could involve altering dimensions, adding structural support, or changing the orientation of the part for printing.

- Re-printing and Re-testing: Print the revised design and repeat the testing process. Each iteration should bring the part closer to the desired performance.

For instance, if a drawer slide repeatedly binds at a specific point, an iterative approach might involve slightly widening the channel in the CAD model by 0.1mm, re-printing, and testing again. If this resolves the binding, the refinement is successful. If it introduces looseness, the next iteration might involve a smaller adjustment or a different approach to address the friction.

This systematic refinement process ensures the final part is not only functional but also robust and durable.

Advanced Considerations and Alternatives

As you become more proficient with 3D printing functional drawer replacement parts, you’ll discover opportunities to enhance designs and explore alternative manufacturing approaches. This section delves into advanced techniques and comparisons that can elevate the quality and functionality of your printed components.

Design Optimization and Stress Analysis Software

For critical drawer components that experience significant stress or require precise load-bearing capabilities, specialized software can provide invaluable insights. These tools go beyond basic CAD modeling to simulate how a part will perform under various conditions.By utilizing finite element analysis (FEA) within these software packages, designers can identify potential weak points in their 3D models before printing. This allows for iterative design improvements, such as reinforcing specific areas or altering geometry to better distribute stress.

The result is a more robust and durable replacement part that is less likely to fail over time. Examples of such software include ANSYS, SolidWorks Simulation, and Fusion 360’s simulation tools, which offer varying levels of complexity and accessibility for both hobbyists and professionals.

Integrating Metal Components and Hardware

While 3D printing excels at creating complex plastic geometries, there are instances where incorporating metal components can significantly improve strength, durability, or functionality. This hybrid approach allows you to leverage the best of both worlds.Common methods for integration include designing the 3D printed part with specific cavities or mounting points for standard metal hardware such as screws, nuts, bearings, or even small shafts.

For example, a drawer slide runner might be printed with integrated channels for metal ball bearings to ensure smooth operation, or a handle might be designed to securely house threaded metal inserts for robust screw attachment. Another advanced technique involves embedding metal rods or plates within the printed part during the printing process for added rigidity, particularly useful for structural elements.

Comparison of 3D Printing with Traditional Manufacturing

D printing offers distinct advantages over traditional manufacturing methods when producing small-batch or custom drawer replacement parts. Understanding these differences helps in choosing the most appropriate production technique.Traditional methods like injection molding or CNC machining are highly efficient for mass production, offering excellent precision and material consistency. However, they typically involve significant setup costs, long lead times for tooling, and are economically unviable for producing just one or a few replacement parts.

3D printing, on the other hand, excels in its ability to produce highly customized parts on demand with minimal setup. It allows for rapid prototyping and iteration, making it ideal for unique or obsolete components where traditional tooling would be prohibitively expensive. The material variety in 3D printing also continues to expand, offering options for different performance requirements.

“For unique, low-volume, or obsolete parts, 3D printing often presents a more cost-effective and time-efficient solution compared to the tooling and setup required for traditional manufacturing.”

Replicating Complex Drawer Mechanisms

The versatility of 3D printing, especially with advanced materials and printing techniques, allows for the creation of intricate drawer mechanisms that might be difficult or impossible to replicate with simpler manufacturing methods.Examples include multi-part drawer slides with integrated rollers, sophisticated locking mechanisms, or even specialized drawer organizers with articulated components. For instance, a custom-designed soft-close mechanism for a drawer, which typically involves several small, precisely shaped parts, can be successfully printed and assembled.

Another complex example could be a telescoping drawer slide system that requires very tight tolerances between interlocking components, achievable with high-resolution 3D printing.

Sourcing and Sharing Designs for Common Drawer Components

The 3D printing community thrives on sharing designs, making it easier to find existing models for common drawer components rather than designing them from scratch. This collaborative approach saves time and effort.Platforms like Thingiverse, MyMiniFactory, and Cults3D host vast libraries of user-uploaded 3D models. Searching these repositories for terms like “drawer slide,” “drawer handle,” “drawer knob,” or specific part names for popular furniture brands can often yield ready-to-print solutions.

For those who do design their own parts, contributing back to these communities helps others and fosters innovation. When sourcing designs, it’s always advisable to check user comments and reviews for feedback on printability and fit.

Closure

In conclusion, mastering the art of 3D printing functional replacement parts for drawers offers a practical and empowering approach to home repair and customization. By following the detailed steps Artikeld, from material selection and design to printing and installation, you can confidently create durable, precise, and perfectly fitting components. This process not only saves time and money but also fosters a deeper understanding of material properties and design for longevity, ensuring your drawers remain in optimal working condition for years to come.