Embark on a captivating journey into the world of custom lithophanes, where cherished memories and intricate designs are transformed into stunning illuminated art. This comprehensive guide will illuminate the path from understanding the fundamental principles of lithophanes to mastering the art of their creation and display.

We will delve into the fascinating history and science behind these unique creations, exploring how light interacts with specially crafted reliefs to reveal breathtaking images. From selecting the perfect photograph to navigating the intricacies of design software and 3D printing, every step will be clearly explained, empowering you to bring your vision to life with precision and creativity.

Understanding Lithophanes

A lithophane is a unique art form and photographic technique that transforms a seemingly opaque object into a translucent image when backlit. The magic lies in the varying thickness of the material, which allows light to pass through at different intensities, revealing intricate details and gradients. This interplay of light and shadow creates a captivating visual experience, making lithophanes a distinctive way to display photographs or artwork.The fundamental principle behind a lithophane is the modulation of light transmission.

A lithophane is essentially a thin sheet of translucent material, typically plastic or porcelain, where the image is created by variations in thickness. Areas that are thinner allow more light to pass through, appearing brighter, while thicker areas block more light, appearing darker. This gradual change in thickness, meticulously controlled, forms the grayscale image.

Materials for Lithophane Creation

The choice of material significantly impacts the final aesthetic and durability of a lithophane. While modern 3D printing has made lithophanes highly accessible, traditional methods also exist. The key characteristic is translucency and the ability to achieve fine variations in thickness.

- 3D Printing Filament: This is the most common material for contemporary lithophanes. PLA (Polylactic Acid) is a popular choice due to its ease of printing, availability in various colors, and good translucency when printed thinly. PETG and ABS can also be used, offering different properties like increased durability or temperature resistance.

- Porcelain: Historically, lithophanes were crafted from porcelain. This involved molding or carving designs into thin porcelain sheets. When lit from behind, the translucent porcelain reveals the image with a soft, warm glow. This method is labor-intensive and requires specialized ceramic firing techniques.

- Wax: Early forms of lithophanes, particularly in the 19th century, were sometimes made from wax. While less common today due to fragility and susceptibility to heat, wax offered a unique translucent quality.

- Resin: UV-curable resins used in stereolithography (SLA) or Digital Light Processing (DLP) 3D printing can also produce highly detailed lithophanes. These resins often offer excellent clarity and can capture very fine details.

History and Evolution of Lithophane Technology

The concept of creating images through varying light transmission has a fascinating history, evolving from traditional crafts to modern digital fabrication. The term “lithophane” itself originates from the Greek words “lithos” (stone) and “phaino” (to appear), reflecting its early development with stone-like materials.The origins of lithophanes can be traced back to the late 18th century in France, with porcelain lithophanes gaining significant popularity in the mid-19th century.

These were often produced by skilled artisans who would engrave or mold intricate scenes, portraits, and religious imagery onto thin porcelain panels. When illuminated from behind, these pieces would display a detailed and delicate image, often used as decorative elements in lampshades, windows, and screens.The advent of photography in the mid-19th century led to lithophanes being created from photographic negatives.

This allowed for the reproduction of personal portraits and landscapes, making them a cherished form of personalized art. The process involved transferring photographic emulsions onto thin, translucent materials and then developing them to create the varying thickness required for the image.With the rise of 3D printing technology in the late 20th and early 21st centuries, lithophanes experienced a resurgence. Digital design software allows for the conversion of digital images into printable 3D models, where the thickness of the model directly corresponds to the grayscale values of the image.

This democratization of the technology has made lithophanes accessible to hobbyists and professionals alike, allowing for the creation of custom lithophanes from virtually any digital photograph.

The Visual Effect of Light Through a Lithophane

The captivating allure of a lithophane is entirely dependent on the way light interacts with its varying thickness. This interplay creates a visual experience that is both subtle and profound, transforming a flat object into a luminous display.When a lithophane is illuminated from behind, the light passes through the material at different rates depending on its thickness. The thinnest areas of the lithophane, corresponding to the brightest parts of the original image, allow the most light to pass through, appearing as luminous highlights.

Conversely, the thickest areas, representing the darkest parts of the image, block a significant amount of light, appearing as deep shadows.The gradient of thickness between these extremes creates a smooth transition of light intensity, resulting in a grayscale image with remarkable depth and detail. This effect is often described as ethereal, soft, and almost painterly. Unlike a standard photograph that relies on reflected light, a lithophane generates its own illumination, giving the image a unique, internal glow.

The beauty of a lithophane lies in its ability to reveal detail only when lit, transforming a mundane object into a glowing canvas of light and shadow.

The visual impact can be further enhanced by the color of the light source. A warm-toned light can give the lithophane a vintage or cozy feel, while a cooler light might emphasize crisp details. The ambient light of the room also plays a role, influencing the perceived contrast and overall mood of the displayed image. This dynamic interaction with light makes each lithophane a living piece of art, constantly changing with its environment.

Designing Your Lithophane Image

The journey to a stunning custom lithophane begins with selecting and preparing the perfect image. This stage is crucial as it directly influences the final quality and detail of your 3D printed artwork. We will explore the characteristics of images that translate best into lithophanes, the steps involved in choosing and refining your source material, and the process of converting it into a printable 3D model.

Suitable Image Types and Characteristics

Not all photographs are equally suited for lithophane creation. The magic of a lithophane lies in its ability to reveal detail through varying light transmission, meaning contrast and tonal range are paramount. Images with strong highlights and deep shadows will produce the most dramatic and visually appealing results.

Key Characteristics for Optimal Lithophanes:

- High Contrast: Images with a significant difference between the lightest and darkest areas will render with the most definition.

- Detailed Tonal Gradients: Smooth transitions between light and dark shades allow for subtle variations in thickness, creating nuanced detail.

- Clear Subject Matter: A well-defined subject, whether it’s a face, a landscape, or an object, will stand out more effectively than a cluttered scene.

- Absence of Fine, Unconnected Lines: Very thin, disconnected lines or small, isolated elements can sometimes be difficult for 3D printers to reproduce accurately at lithophane scale, potentially leading to breakages or lost detail.

- Simple Backgrounds: While not strictly mandatory, simpler backgrounds help the main subject pop and prevent visual distraction.

Selecting and Preparing a Source Image

Choosing the right photograph is the first creative decision. Consider what you want to capture and how it will look when illuminated from behind. Once you have a potential candidate, preparation is key to unlocking its lithophane potential.

Image Selection Considerations:

- Personal Significance: Lithophanes make excellent personalized gifts. Think about cherished memories, portraits of loved ones, or pets.

- Artistic Merit: Consider photographs with strong composition and aesthetic appeal that will translate well into a light-sculpted format.

- Resolution and Quality: Start with the highest resolution image available. Low-resolution images will result in pixelated or blurry lithophanes.

Image Preparation Steps:

- Cropping: Remove any unnecessary elements from the image to focus on the subject.

- Adjusting Brightness and Contrast: This is the most critical step. Increase contrast to emphasize the differences between light and dark areas. Carefully adjust brightness to ensure highlights are not blown out and shadows retain detail.

- Sharpening: A subtle sharpening can help define edges and details, making them more visible in the printed lithophane. Be careful not to over-sharpen, which can introduce artifacts.

- Grayscale Conversion: Lithophane software typically works with grayscale images, as the intensity of each pixel (from black to white) directly corresponds to the thickness of the 3D model.

Converting a 2D Image into a 3D Lithophane Model

The transformation from a flat image to a printable 3D object is facilitated by specialized software. These tools interpret the grayscale values of your image and generate a heightmap, which then dictates the varying thickness of the lithophane.

Step-by-Step Conversion Process:

- Import Image: Open your prepared grayscale image in lithophane conversion software.

- Set Parameters: Configure settings such as the desired size of the lithophane, the thickness of the base (if applicable), and the maximum thickness of the material. These parameters will influence the overall scale and detail.

- Generate 3D Model: The software will process the image, mapping darker pixels to thinner areas and lighter pixels to thicker areas (or vice versa, depending on the software’s convention). This creates a mesh or STL file.

- Preview and Refine: Most software allows you to preview the generated 3D model. Inspect it for any unexpected artifacts or areas where detail might be lost. Some software offers tools to smooth or adjust the model.

- Export STL: Save the generated 3D model in STL format, which is the standard for 3D printing.

Comparison of Software Tools for Image Preparation

Several software options are available, ranging from simple online converters to more advanced image editing suites. The choice often depends on your familiarity with graphic design software and the level of control you desire.

Popular Software Options and Their Functionalities:

- Online Lithophane Generators (e.g., Lithophane Maker, ItsLitho):

- Functionality: These are user-friendly, web-based tools that allow you to upload an image, adjust basic settings (size, thickness, shape), and directly download an STL file. They are excellent for beginners.

- Pros: Easy to use, no installation required, quick results.

- Cons: Limited advanced editing capabilities, less control over fine-tuning.

- Image Editing Software (e.g., Adobe Photoshop, GIMP):

- Functionality: These programs offer comprehensive tools for image manipulation. You can perform detailed adjustments to contrast, brightness, sharpness, and convert images to grayscale with precise control. The output would then be used by a separate lithophane generator.

- Pros: Maximum control over image preparation, ability to fix imperfections, enhance details.

- Cons: Steeper learning curve, requires installation, and you’ll still need a separate tool to convert the image to an STL.

- Dedicated Lithophane Software (e.g., LithoCan, Cura’s Lithophane Feature):

- Functionality: Some 3D slicing software, like Ultimaker Cura, has built-in features to directly convert images into lithophanes. Other dedicated programs offer a blend of image editing and STL generation.

- Pros: Integrated workflow, often optimized for 3D printing.

- Cons: Feature sets can vary; some may be less intuitive than online tools.

Checklist of Essential Image Properties for Optimal Lithophane Results

To ensure your lithophane turns out beautifully, consider these essential properties when selecting and preparing your image.

Image Properties Checklist:

- [ ] High resolution (e.g., 1000×1000 pixels or larger is recommended for good detail).

- [ ] Strong contrast between light and dark areas.

- [ ] Smooth tonal gradients for subtle detail.

- [ ] Clear, well-defined subject.

- [ ] Image converted to grayscale.

- [ ] Adjustments made to brightness and contrast to maximize detail without clipping.

- [ ] Image sharpened appropriately to enhance definition.

- [ ] Minimal noise or artifacts in the image.

- [ ] Subject fills a significant portion of the frame without being too small or too large.

- [ ] Consider the orientation: portraits often work well in vertical orientation, landscapes in horizontal.

Software and Tools for Lithophane Creation

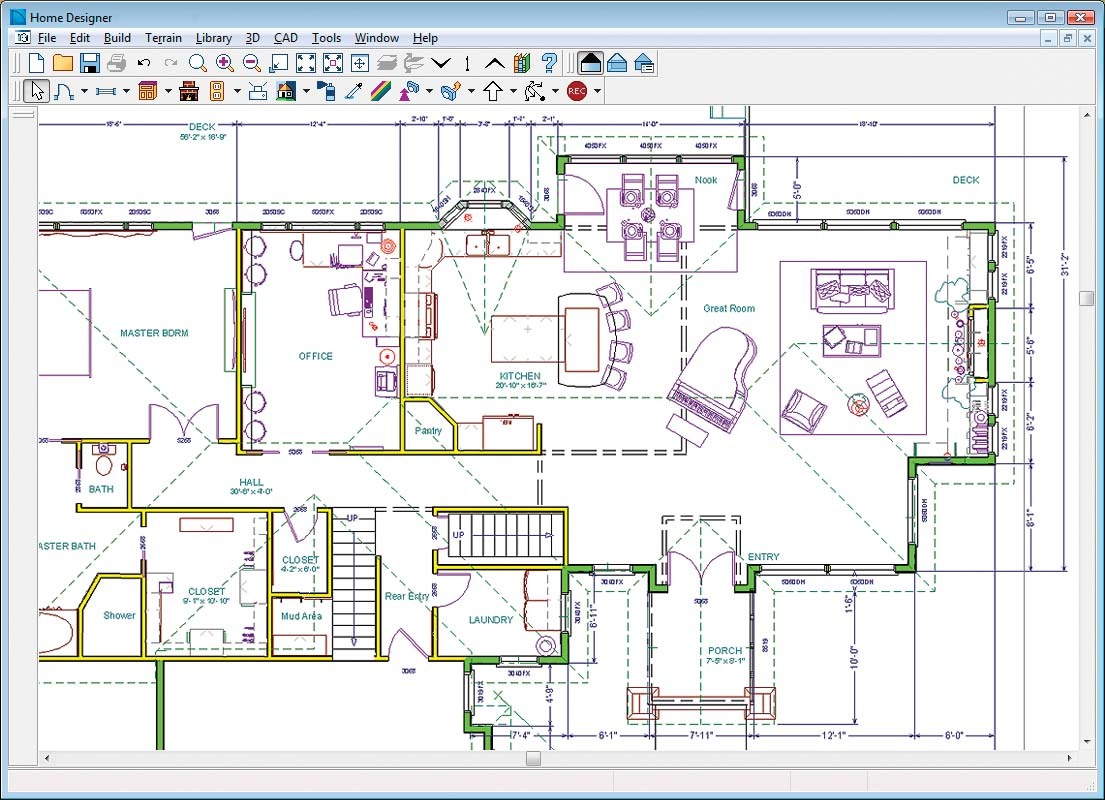

Once you have a clear vision for your lithophane, the next crucial step is selecting the right software to transform your image into a printable 3D model. The process involves specialized tools that interpret the grayscale values of your image and translate them into varying thicknesses of plastic, which, when backlit, reveal the image. This section will guide you through the types of software available and highlight popular options to help you make an informed decision.The primary software categories for lithophane design revolve around image processing and 3D model generation.

Image processing tools are essential for preparing your source image, adjusting contrast, and ensuring it’s in a suitable format. Following this, lithophane generation software takes the processed image and converts it into a 3D mesh, typically in an STL file format, which is then ready for slicing and 3D printing.

Lithophane Generation Software Overview

Numerous software options are available for creating lithophanes, ranging from simple, user-friendly web-based tools to more advanced desktop applications offering extensive customization. The choice often depends on your technical skill level, the desired complexity of your lithophane, and whether you prefer free or paid solutions.Popular free options often provide a straightforward way to generate basic lithophanes quickly. These are excellent for beginners or for those who need to create a lithophane without a steep learning curve.

Paid software, on the other hand, typically offers more granular control over the design process, allowing for intricate details, custom shapes, and advanced features that can elevate the final print.

Free and Paid Lithophane Software Options

Here’s a look at some commonly used software, categorized by their cost and accessibility:

- Free Online Generators: Websites like Lithophane Maker (lithophanemaker.com) and MakePrintable (makeprintable.com) offer intuitive interfaces where you can upload an image, adjust basic settings, and download an STL file. These are ideal for quick, no-installation solutions.

- Free Desktop Software: While less common for dedicated lithophane generation, some 3D modeling software with image-to-mesh capabilities can be adapted. However, dedicated free lithophane tools are more prevalent online.

- Paid Software: Options like Cura (while primarily a slicer, it has some lithophane capabilities through plugins) and specialized 3D modeling suites (like Fusion 360 or Blender, which require more advanced skills to adapt for lithophanes) can offer greater flexibility. However, dedicated paid lithophane generators are less common than free online tools, as the core functionality is often achieved with free resources.

Comparative Table of Lithophane Design Programs

To provide a clearer picture, here is a comparative table of leading lithophane design programs, focusing on key features relevant to users.

| Software Name | Ease of Use | Customization Options | Output Formats |

|---|---|---|---|

| Lithophane Maker (Online) | Beginner-friendly | Basic adjustments (thickness, resolution, shape) | STL |

| MakePrintable (Online) | Beginner-friendly | Good range of basic to intermediate settings | STL |

| ImageToSTL (Various implementations, often command-line or basic GUI) | Intermediate to Advanced (depending on implementation) | Varies greatly; can be very detailed in specific implementations | STL |

Resolution and Detail Settings in Design Software

The resolution and detail settings within your chosen lithophane design software are paramount to the quality of your final print. These settings directly influence how accurately the software translates the nuances of your image into the 3D model.When adjusting these settings, consider the following:

- Image Resolution: The higher the resolution of your input image, the more detail the software can work with. A low-resolution image will result in a blocky or pixelated lithophane, regardless of the software’s settings.

- Model Resolution/Detail: This setting often dictates the density of the mesh that forms your lithophane. Higher detail settings will create a smoother, more intricate model with finer gradations of thickness, leading to a more realistic and detailed final image when backlit. However, excessively high detail can lead to very large file sizes and longer processing times.

- Thickness and Contrast: These are fundamental parameters. The maximum and minimum thickness of the lithophane determine the range of light transmission, directly impacting the contrast and vibrancy of the final image. Software often allows you to fine-tune these values to achieve the desired visual effect.

It is often beneficial to experiment with these settings on a test image or a small section of your design. For instance, a setting of “high detail” in one program might correspond to a specific number of facets or a level of subdivision that you can adjust. A common approach is to start with default settings and then iteratively increase the detail or adjust thickness parameters until the desired visual fidelity is achieved.

“The interplay between image quality and software detail settings is the bedrock of a successful lithophane print.”

3D Modeling and Slicing for Printing

After you have prepared your lithophane image, the next crucial step is to transform this 2D data into a 3D printable model. This process involves using specialized software to interpret the grayscale values of your image and translate them into varying thicknesses of plastic. These thickness variations are what allow light to pass through differently, creating the recognizable image when illuminated from behind.

Once the 3D model is generated, it needs to be prepared for your specific 3D printer using slicing software. This software breaks down the 3D model into thin horizontal layers, defining the exact path the printer’s nozzle will follow for each layer.The generation of a 3D model from an image is typically handled by dedicated lithophane creation software or plugins for popular 3D modeling programs.

These tools analyze the brightness of each pixel in your image. Brighter areas are usually translated into thinner sections of the lithophane, allowing more light to pass through, while darker areas become thicker, blocking more light. The output of this process is a standard 3D model file format, most commonly an STL (Stereolithography) file, which is widely compatible with slicing software.

Generating the 3D Model File

The conversion from a 2D image to a 3D lithophane model relies on the principle of mapping image intensity to physical thickness. Most lithophane generators offer options to control the shape of the lithophane (e.g., flat, curved, cylindrical) and the maximum and minimum thickness. For instance, a brighter pixel might correspond to a thickness of 0.5mm, while a darker pixel could be 3mm thick.

The software interpolates these values across the entire image, creating a mesh that represents the surface of the lithophane. Some advanced tools allow for fine-tuning of the “contrast” or “gamma” of the image before conversion, which can significantly impact the final print’s clarity and detail.

Critical Slicing Settings for Lithophanes

Preparing a lithophane for printing involves meticulous adjustment of slicing software parameters. These settings directly influence how the printer interprets the 3D model and, consequently, the quality of the final lithophane. The goal is to achieve a balance between fine detail, smooth transitions in shading, and sufficient structural integrity. It’s important to note that optimal settings can vary slightly depending on the specific printer, filament used, and the complexity of the lithophane design.To achieve the best results, several key slicing parameters require careful consideration.

These include layer height, infill density, wall thickness, and print speed. Understanding the impact of each setting allows for informed adjustments to produce a visually appealing and well-formed lithophane.

Layer Height

Layer height is one of the most impactful settings for lithophane quality. It determines the thickness of each individual layer deposited by the 3D printer.

- Effect on Detail: A smaller layer height (e.g., 0.1mm or 0.12mm) results in a higher resolution lithophane with smoother gradients and finer details. This is because the printer is making smaller steps vertically, allowing for more subtle variations in thickness.

- Effect on Print Time: Conversely, reducing the layer height significantly increases print time. A lithophane printed with 0.1mm layers will take considerably longer than one printed with 0.2mm layers.

For most lithophanes, a layer height between 0.1mm and 0.16mm is recommended to capture sufficient detail without making the print excessively long.

Infill Density

Infill density refers to the amount of internal structure within the printed object. For lithophanes, the infill plays a crucial role in light transmission and the overall strength of the print.

- Influence on Light Transmission: Lithophanes are typically printed without infill, or with a very low infill density, and with solid top and bottom layers. This is because infill patterns can create unwanted shadows or diffusion of light, obscuring the image. However, some designs might benefit from a very sparse infill (e.g., 5-10%) to provide internal support, especially for large or complex shapes, without significantly compromising light transmission.

- Structural Integrity: While low infill is preferred for light transmission, the lithophane needs to be structurally sound. The wall thickness and the inherent strength of the filament are primary contributors to structural integrity.

The general recommendation for lithophanes is to print with 0% infill and rely on solid walls and top/bottom layers (if applicable to the specific lithophane design) for structural support.

Wall Thickness

Wall thickness, also known as shell thickness or perimeter count, dictates the number of solid lines printed around the outer edges of the model. This setting is critical for defining the shadows and highlights in your lithophane.

- Role in Defining Shadows and Highlights: A thicker wall in the darker areas of your image translates to a more opaque section, blocking more light and creating deeper shadows. Conversely, thinner walls in the brighter areas allow more light to pass through, creating highlights. For lithophanes, it’s often beneficial to have at least 2-3 walls to ensure sufficient opacity in the darker regions and to provide a clean surface for the print.

Experimenting with wall thickness can help fine-tune the contrast and depth of the printed image.

Print Speed

Print speed affects the quality and reliability of the print. For lithophanes, a slower print speed is generally preferred.

- Recommendations for Optimal Results: Printing too fast can lead to artifacts such as ringing, poor layer adhesion, and inconsistent extrusion, all of which can degrade the image quality. A print speed between 30mm/s and 50mm/s is a good starting point. For intricate details and smooth gradients, even slower speeds might be beneficial. It is also advisable to print the outer walls slightly slower than the inner walls to ensure a cleaner surface finish.

Workflow for Exporting and Importing Models

The workflow for preparing your lithophane for printing involves a clear sequence of steps. Once you have generated your STL file from the lithophane software, you will import it into your chosen slicing software.

- Export STL: After designing your lithophane in the specialized software, export it as an STL file. Ensure you select a suitable resolution for the STL export; a higher resolution will result in a smoother 3D model but a larger file size.

- Import into Slicer: Open your preferred slicing software (e.g., Cura, PrusaSlicer, Simplify3D). Use the “Import” or “Open” function to load your STL file onto the virtual build plate.

- Apply Settings: Navigate through the slicing software’s settings menu. Carefully adjust the parameters discussed above: layer height, infill density, wall thickness, and print speed. You may also want to adjust temperature settings for your specific filament.

- Slice and Preview: Once all settings are configured, initiate the slicing process. The software will then generate the G-code file, which contains the instructions for your 3D printer. Before saving, it is highly recommended to use the “Preview” mode. This allows you to visually inspect each layer of the print, identify any potential issues, and confirm that the lithophane will be printed as intended.

- Save G-code: If the preview looks satisfactory, save the generated G-code file to your SD card or send it directly to your printer via USB or Wi-Fi, depending on your printer’s capabilities.

3D Printing Techniques and Materials

Designing and preparing your lithophane is only half the journey; the actual 3D printing process is where your digital image truly comes to life. Selecting the right printing technology, filament, and settings is crucial for achieving a visually stunning and detailed lithophane. This section will guide you through the essential 3D printing considerations to ensure your custom lithophane is a success.Lithophanes are unique in their printing requirements due to their reliance on translucent materials and fine detail.

The goal is to create a print where light passing through varying thicknesses of plastic reveals the image. This necessitates a careful balance between print resolution, material properties, and structural integrity.

Suitable 3D Printing Technologies

The most effective 3D printing technologies for lithophanes are those that offer high resolution and precise layer control, allowing for the subtle variations in thickness required to form the image.

- Fused Deposition Modeling (FDM): This is the most common and accessible technology for lithophane printing. FDM printers build objects layer by layer using thermoplastic filaments. Their widespread availability and affordability make them an excellent choice for hobbyists and professionals alike. The key to successful lithophanes with FDM lies in achieving very thin layers and minimizing visible layer lines.

- Stereolithography (SLA) and Digital Light Processing (DLP): These resin-based printing technologies offer significantly higher resolution and smoother surface finishes compared to FDM. SLA and DLP printers use a UV light source to cure liquid photopolymer resin layer by layer. While generally more expensive and requiring more post-processing (washing and curing), they can produce incredibly detailed and smooth lithophanes with minimal visible layer lines, often resulting in a more polished aesthetic.

Recommended Filament Types and Properties

The choice of filament directly impacts the translucency, detail, and overall appearance of your lithophane. Certain properties are highly desirable to maximize the visual effect.

- PLA (Polylactic Acid): This is the most popular filament for lithophanes due to its ease of printing, low warping, and good translucency when printed thinly. PLA is biodegradable and comes in a vast array of colors. For lithophanes, look for PLA filaments that are naturally translucent or have a matte finish, as glossy finishes can sometimes create unwanted reflections.

- PETG (Polyethylene Terephthalate Glycol): PETG offers a good balance of strength, durability, and translucency. It is more impact-resistant and temperature-resistant than PLA, making it suitable for lithophanes that might be handled more frequently or exposed to slightly warmer environments. However, PETG can be stringier than PLA, requiring careful calibration of retraction settings during printing.

- Specialty Translucent Filaments: Many filament manufacturers offer filaments specifically designed for lithophanes or with enhanced translucency. These often have additives that improve light diffusion and clarity. If available, these are excellent choices for achieving the best possible visual results.

When selecting a filament, always consider its light transmission properties. A filament that allows light to pass through evenly without excessive diffusion or absorption will render the image with greater contrast and detail.

Common Print Orientations

The way you orient your lithophane model on the print bed can significantly affect print quality, support requirements, and the final visual outcome.

- Standing Upright (Vertical): This is the most common orientation for many lithophanes, especially those designed to be backlit. Printing vertically means the layers are stacked horizontally, creating a thin sheet that is then illuminated from behind. This orientation generally produces the best image detail as the light passes through the thinnest parts of the plastic, revealing the image. However, it can sometimes require supports if the lithophane has overhangs or complex shapes, which can mar the surface.

- Lying Flat (Horizontal): Printing a lithophane flat on the print bed means the layers are built vertically, perpendicular to the image plane. This orientation can be beneficial for lithophanes that are intended to be used as coasters or small, flat decorative items where backlighting isn’t the primary display method. It often requires no supports and can result in a very smooth top surface.

However, the image detail might be less pronounced compared to vertical printing, as the light would be passing through a thicker cross-section of material for the same image area.

- Curved or Shaped Lithophanes: For lithophanes designed with a curve or integrated into a larger object, the orientation will be dictated by the model’s geometry. The key is to ensure that the thinnest parts of the lithophane are still oriented to allow light to pass through effectively, and that overhangs are managed with appropriate support structures.

Troubleshooting Common Printing Issues

Even with careful preparation, lithophane printing can sometimes present challenges. Understanding common issues and their solutions is key to achieving a successful print.

Layer Lines and Surface Finish

A common issue is the visibility of layer lines, which can detract from the image.

- Cause: Standard layer heights, inadequate cooling, or printing too fast.

- Solution: Use a smaller layer height (e.g., 0.1mm or less). Ensure your printer’s cooling fan is set to an appropriate level to solidify the plastic quickly after extrusion. Experiment with slightly slower print speeds.

Stringing and Blobs

Excessive stringing or small blobs of plastic can appear on the surface, obscuring detail.

- Cause: Incorrect retraction settings, filament moisture, or printing temperature too high.

- Solution: Calibrate your printer’s retraction distance and speed. Ensure your filament is dry; consider using a filament dryer. Print a temperature tower to find the optimal printing temperature for your specific filament.

Poor Detail or Washed-Out Image

The image appears faint, lacking contrast, or details are not sharp.

- Cause: Filament too opaque, print thickness too uniform, or incorrect lighting setup for viewing.

- Solution: Try a more translucent filament. Ensure your lithophane design has a good range of thickness variation (e.g., very thin for highlights, thicker for shadows). When viewing, use a strong, diffuse light source behind the lithophane.

Warping and Bed Adhesion

The print may lift off the print bed during printing, especially with larger lithophanes.

- Cause: Poor bed adhesion, drafts, or printing with materials prone to warping.

- Solution: Ensure your print bed is clean and properly leveled. Use an adhesion helper like a brim or raft if necessary. Consider using an enclosure for your printer to maintain a stable temperature and prevent drafts.

Visual Outcomes with Different Filament Colors

The color of the filament used for your lithophane has a significant impact on the final visual appearance and the perceived contrast of the image.

- White and Light Colors (e.g., Light Gray, Pale Yellow): These colors generally produce the brightest and most luminous lithophanes. White filament allows for excellent light transmission and creates high contrast, making details stand out clearly. Light gray can offer a slightly softer, more nuanced image compared to pure white.

- Translucent Natural/Clear: Printing with clear or natural translucent filament often results in a very pure and clean image. The light passes through with minimal color distortion, allowing the inherent properties of the filament to dictate the light diffusion. This can be excellent for achieving subtle gradients and fine details.

- Darker Colors (e.g., Black, Dark Blue, Red): These colors are generally less suitable for traditional lithophanes that rely on backlighting. They tend to absorb more light, resulting in a very faint or almost invisible image when illuminated from behind. However, they can be used for unique effects or when the lithophane is intended to be viewed in ambient light, where the raised and lowered areas create a tactile relief.

Some “reverse” lithophane designs utilize dark filaments to create embossed images.

- Color-Changing Filaments: Filaments that change color based on temperature can create interesting, albeit unpredictable, lithophanes. The color shifts can add an artistic layer to the image, but the primary image detail might be less defined due to the color variations.

It’s important to note that even within the same color family, different filament brands and types can exhibit varying levels of translucency and color saturation, leading to slightly different visual results. Always consider the intended viewing method and desired aesthetic when choosing your filament color.

Post-Processing and Displaying Your Lithophane

Once your custom lithophane has been successfully 3D printed, the journey to its final, breathtaking form involves careful post-processing and thoughtful display. These steps are crucial for refining the print quality and ensuring your creation captivates viewers. Proper finishing techniques can elevate a good print into a truly stunning piece of art, highlighting the subtle nuances of light and shadow that define a lithophane.The appearance of a lithophane is intrinsically linked to how light interacts with it.

Understanding this relationship is key to maximizing its aesthetic impact. Whether illuminated by natural daylight or a dedicated light source, the subtle variations in thickness that represent your image will come to life. The goal is to present your lithophane in a way that allows these details to be fully appreciated, transforming a simple 3D print into a glowing masterpiece.

Cleaning and Refining the Printed Lithophane

After printing, lithophanes may retain remnants of the printing process, such as support structures or minor surface imperfections. Careful removal of these elements is essential for a clean, professional look. The goal is to achieve a smooth surface that allows light to pass through uniformly, without obstruction.Methods for cleaning and refining include:

- Support Removal: Carefully detach any support material used during the printing process. Pliers, hobby knives, and small picks are useful tools for this. Work slowly and deliberately to avoid damaging the delicate lithophane structure.

- Sanding: For a smoother finish, light sanding can be employed. Start with a fine-grit sandpaper (e.g., 400-grit) and progress to finer grits (e.g., 1000-2000 grit) if a polished surface is desired. Always sand in a consistent direction or use circular motions to avoid visible scratch marks. Water-soluble lubricants or water can be used to reduce friction and dust during sanding.

- Deburring: Small imperfections or “strings” left by the 3D printer can be removed with a sharp hobby knife or a small file.

- Acetone Smoothing (for ABS prints): If your lithophane was printed with ABS filament, a brief exposure to acetone vapor can smooth the layer lines, creating a more glass-like finish. This process requires significant caution and should be performed in a well-ventilated area with appropriate safety gear.

Enhancing the Visual Impact

Beyond basic cleaning, several techniques can be employed to further enhance the visual appeal of your finished lithophane. These methods focus on maximizing the contrast and clarity of the image when illuminated.Techniques for enhancing visual impact include:

- Backlighting: This is the most critical element for a lithophane. The image is revealed by light passing through the varying thicknesses of the printed material. The intensity and color of the light source will significantly influence the final appearance.

- Contrast Adjustment: The perceived contrast of the lithophane can be influenced by the surrounding environment. A darker background or frame will generally make the illuminated image appear more vibrant.

- Surface Treatment: While sanding can smooth the surface, some users opt for a light coating of clear sealant or varnish to enhance translucency and provide a uniform sheen. Ensure any coating is applied thinly and evenly to avoid obscuring fine details.

Creative Ideas for Mounting and Displaying Your Lithophane

The way you choose to mount and display your lithophane can dramatically affect its aesthetic appeal and how it integrates into your living space. Creative display solutions can turn a simple print into a focal point, showcasing your personalized artwork in unique ways.Here are several display concepts, ranging from simple to elaborate:

Concept 1: Basic Frame MountA simple wooden or plastic frame to hold the lithophane, allowing light to pass through from behind. This is a straightforward approach that focuses attention on the lithophane itself. The frame can be painted or stained to complement your decor. The lithophane can be secured to the back of the frame with adhesive, or a groove can be incorporated into the frame design to hold it in place.

Concept 2: Illuminated BoxA custom-built box with integrated LED lighting to backlight the lithophane for a dramatic effect. This method provides a controlled and consistent light source, ensuring optimal viewing conditions. The box can be constructed from wood, acrylic, or even 3D printed itself. LEDs can be arranged in a panel or strip behind the lithophane. Consider using diffused LEDs or a diffusion panel to create a softer, more even light distribution.

Concept 3: Window HangerDesigning a method to hang the lithophane in a window, utilizing natural light. This is an excellent way to leverage ambient daylight. The lithophane can be designed with integrated holes for hanging, or a separate frame can be created with a hanging mechanism. Suction cups or small eye hooks can be used to attach it to a windowpane.

Ambient Lighting Conditions and Lithophane Appearance

The ambient lighting conditions in which a lithophane is displayed play a pivotal role in its visual presentation. The interplay between the light source behind the lithophane and the surrounding light in the room creates the final perceived image.The impact of ambient lighting includes:

- Intensity: In a brightly lit room, a lithophane may appear washed out unless the backlight is sufficiently strong. Conversely, in a dim environment, even a moderate backlight can create a striking effect.

- Color Temperature: The color of the light source will affect the color rendition of the lithophane. Warm white LEDs can create a cozy, inviting atmosphere, while cool white LEDs might offer a crisper, more detailed appearance. Natural daylight also varies in color temperature throughout the day.

- Direction: While lithophanes are primarily viewed with light passing through them, ambient light hitting the front surface can also influence the perception. Glare from strong frontal light sources can detract from the image. Positioning the lithophane to minimize direct frontal glare is advisable.

- Contrast with Surroundings: The visual impact is amplified when the lithophane is placed against a contrasting background. A dark wall or a shadowed alcove can make the illuminated image stand out more prominently than a brightly lit, busy environment.

Closure

As we conclude our exploration of how to design and print a custom lithophane, we hope you feel inspired and well-equipped to embark on your own creative endeavors. From the initial spark of an idea to the final, luminous reveal, the process is as rewarding as the finished product. May your lithophanes shine brightly, casting a warm glow and a unique charm upon your surroundings.