With How to Soundproof Your 3D Printer Enclosure at the forefront, this guide opens a window to a remarkably quieter 3D printing experience. We will delve into the common disturbances that emanate from these impressive machines and explore the significant advantages a tranquil printing environment can offer, making your workshop a more pleasant space for everyone.

This comprehensive exploration will dissect the origins of 3D printer noise, from the subtle hum of stepper motors and the vibrations of the frame to the whirring of fans and the movement of filament. Understanding these sources is the crucial first step in effectively mitigating them, paving the way for a more peaceful and productive 3D printing journey.

Understanding the Need for Soundproofing

Many 3D printing enthusiasts find that while the technology is exciting, the accompanying noise can be a significant drawback. A dedicated enclosure for your 3D printer can offer substantial benefits, not just in terms of print quality but also by creating a more pleasant working and living environment. Soundproofing an enclosure addresses the inherent noise generated by these machines, transforming a potentially disruptive hobby into a more harmonious one.D printers, by their nature, involve several moving parts and processes that contribute to their acoustic output.

Understanding these noise sources is the first step in effectively mitigating them. The primary goal of soundproofing is to reduce the decibel level of these noises, making the printer’s operation less intrusive. This not only improves comfort but can also enhance focus and productivity for those working near the printer.

Common Noise Sources in 3D Printers

The operational sounds of a 3D printer can be broadly categorized into distinct types, each with its own characteristics and impact. Recognizing these will help in selecting appropriate soundproofing materials and techniques.

- Stepper Motor Noise: These motors are responsible for precise movements of the print head and bed. They produce a distinct, often high-pitched buzzing or whining sound, especially during rapid acceleration and deceleration. This is a constant component of the printing process.

- Fan Noise: 3D printers utilize several fans for cooling the hotend, the printed parts, and the electronics. These fans generate a continuous whirring or humming sound, the intensity of which varies with fan speed and quality.

- Vibration and Resonance: The rapid movements of the print head and bed, combined with the printer’s frame and internal components, can lead to vibrations. These vibrations can resonate with the enclosure and surrounding surfaces, amplifying the overall noise level and creating a deeper, more pervasive hum.

- Extruder Mechanism Noise: While generally quieter than motors or fans, the gears and mechanisms within the extruder that push filament can also contribute a subtle mechanical clicking or grinding sound.

Benefits of a Quieter 3D Printing Environment

Reducing the noise produced by a 3D printer through enclosure soundproofing offers a multitude of advantages that enhance the overall 3D printing experience. These benefits extend beyond mere noise reduction, impacting productivity, comfort, and even print quality.

- Improved Concentration and Productivity: A quieter workspace allows for better focus, making it easier to concentrate on complex tasks or simply enjoy a more peaceful environment. This is particularly beneficial for those who work or study near their 3D printer.

- Reduced Disturbance to Others: For individuals living in shared spaces, such as apartments or houses with multiple occupants, a soundproofed enclosure significantly minimizes disruption to family members, roommates, or neighbors. This fosters a more harmonious living situation.

- Enhanced Print Quality: While not a direct benefit of soundproofing itself, a well-designed enclosure often contributes to more stable printing conditions. Reduced vibrations from sound dampening materials can sometimes lead to slightly improved print surface finish by minimizing unwanted movements.

- Protection from Environmental Factors: Beyond noise, enclosures also offer protection from dust, drafts, and temperature fluctuations, which can negatively impact print quality. Soundproofing materials often serve a dual purpose in providing some level of insulation.

- A More Pleasant Hobby Experience: Ultimately, 3D printing is a hobby. Reducing the noise makes it more enjoyable and less of a chore, encouraging more frequent and less stressful use of the printer.

Identifying Noise Sources in a 3D Printer

Understanding the specific sources of noise within your 3D printer is the crucial next step in effectively soundproofing its enclosure. By pinpointing these culprits, you can tailor your soundproofing strategies for maximum impact, ensuring a quieter and more pleasant printing environment. Let’s delve into the primary contributors to the auditory landscape of 3D printing.

Mechanical Vibrations from Stepper Motors

Stepper motors are the workhorses of 3D printers, responsible for the precise movements of the print head and build plate along the X, Y, and Z axes. While essential for accurate printing, their operation generates distinct noises. These motors move in discrete steps, and the rapid switching of their internal coils can create a characteristic buzzing or whining sound. Furthermore, the physical vibrations inherent in their operation can be transmitted through the printer’s frame, amplifying the overall noise level.

The intensity of this noise can vary depending on the motor’s quality, its mounting, and the speed at which it’s operating.

Acoustic Resonance from Printer Frame and Components

The physical structure of a 3D printer, including its frame, panels, and various components, can act as a resonator. When excited by vibrations from the stepper motors, cooling fans, or even the movement of the print head, these parts can vibrate at their natural frequencies. This phenomenon, known as acoustic resonance, amplifies specific sound frequencies, leading to a more pronounced and often irritating hum or rattle.

The materials used in the printer’s construction play a significant role; lighter, less rigid frames are more prone to resonating. Even small, seemingly insignificant parts can contribute to this resonance if they are not securely fastened or are made of materials that easily vibrate.

Noise Contributions from Cooling Fans

Cooling fans are vital for maintaining optimal printing temperatures, both for the hotend and the printed parts. However, they are also a significant source of noise. The primary contributors to fan noise are the air turbulence created as the fan blades spin and the mechanical noise from the fan’s motor. Smaller, higher-speed fans generally produce a higher-pitched whine, while larger, slower fans might create a more pronounced whooshing sound.

The quality and design of the fan, as well as its mounting, can greatly influence the volume and character of the noise it produces. Dust accumulation on fan blades can also lead to imbalance and increased noise.

Sounds Associated with Filament Movement and Extrusion

The process of filament feeding and extrusion also contributes to the overall sound profile of a 3D printer. As the extruder gears grip and push the filament, there can be a subtle grinding or clicking sound, especially if the filament is not feeding smoothly or if there is any resistance. The movement of the filament through the Bowden tube (if applicable) can also create a faint swishing or rustling noise.

When the molten filament is deposited onto the build plate, the slight hiss of the hot plastic meeting the air can be audible, particularly during rapid infill patterns or when printing with certain materials.

Principles of Soundproofing for Enclosures

Effectively soundproofing your 3D printer enclosure involves understanding how sound behaves and how to manipulate it. This section delves into the fundamental principles that guide the design and material selection for an effective sound-dampening enclosure. By applying these concepts, you can significantly reduce the noise emanating from your printer.Soundproofing is not a single technique but rather a combination of strategies that work together to minimize noise.

The core principles revolve around preventing sound from escaping your enclosure and reducing the vibrations that generate noise in the first place. These principles can be broadly categorized into absorption and blocking, with each playing a crucial role in the overall effectiveness of your enclosure.

Sound Absorption and Blocking

Soundproofing enclosures utilize two primary mechanisms to combat noise: absorption and blocking. Sound absorption deals with converting sound energy into heat, thereby reducing the intensity of sound waves. Sound blocking, on the other hand, focuses on preventing sound waves from passing through a barrier. Both are essential for a comprehensive soundproofing solution.Sound absorption is typically achieved by using porous materials that can trap sound waves.

When sound waves enter the pores of these materials, they collide with the material’s structure, causing friction and dissipating their energy as heat. This is particularly effective for reducing echoes and reverberation within the enclosure, making the overall sound less harsh.Sound blocking relies on creating dense and massive barriers that reflect or absorb sound waves. The greater the mass of the barrier, the more energy is required to vibrate it, and consequently, the less sound energy will be transmitted through it.

This principle is fundamental to preventing noise from escaping the enclosure.

The Role of Mass in Preventing Sound Transmission

Mass is a critical factor in sound blocking. Materials with higher density and mass are more effective at reflecting and absorbing sound energy, thus reducing its transmission. This is why heavier materials are generally better for soundproofing than lighter ones.The concept is straightforward: sound travels as vibrations. When sound waves strike a barrier, they cause it to vibrate. If the barrier is massive and rigid, it requires more energy to vibrate significantly, meaning less sound energy will pass through to the other side.

For instance, a thin sheet of plastic will transmit more sound than a thick sheet of MDF (Medium-Density Fiberboard) of the same size, because the MDF has significantly more mass.

Damping Materials Dissipate Vibrational Energy

Damping materials are specifically designed to absorb vibrational energy and convert it into heat, thereby reducing resonance and the transfer of vibrations. This is particularly important for the moving parts of a 3D printer, such as the motors and the print bed, which can generate significant vibrations.These materials are often viscoelastic, meaning they exhibit both viscous and elastic properties. When subjected to vibration, they deform and then return to their original shape, but in this process, some of the energy is lost as heat due to internal friction.

This effectively “dampens” the vibrations, preventing them from propagating and radiating as sound. Common examples include rubber mats, specialized acoustic foams, and even asphalt-based sound deadening mats used in automotive applications.

Comparing Soundproofing Strategies

Various strategies can be employed to soundproof a 3D printer enclosure, each with its own strengths and weaknesses. A truly effective enclosure often combines multiple approaches to maximize noise reduction.Here’s a comparison of common soundproofing strategies:

- Mass Loading: Adding dense materials like MDF, plywood, or mass-loaded vinyl (MLV) to the enclosure walls. This is highly effective for blocking low-frequency sounds.

- Absorption: Incorporating porous materials like acoustic foam, mineral wool, or fiberglass insulation inside the enclosure. This is excellent for reducing mid and high-frequency sounds and echoes.

- Damping: Applying viscoelastic materials to surfaces that vibrate, such as the printer’s frame or enclosure panels, to dissipate vibrational energy.

- Decoupling: Separating the printer from its supporting surface using vibration-isolating feet or mounts. This prevents vibrations from traveling through the floor or desk.

- Sealing: Ensuring the enclosure is as airtight as possible, with minimal gaps or openings. Sound will find any path of least resistance.

The effectiveness of each strategy depends on the type of noise being addressed. For instance, mass loading is crucial for blocking the low-frequency hum of the power supply and motors, while absorption is key to taming the higher-frequency whine of cooling fans and the printer’s movement. A multi-layered approach, combining these techniques, will yield the best results. For example, building an enclosure with MDF walls (mass) lined with acoustic foam (absorption) and applying damping mats to the printer’s chassis (damping) would create a significantly quieter printing environment.

Selecting Appropriate Soundproofing Materials

Choosing the right materials is paramount to effectively soundproofing your 3D printer enclosure. The goal is to absorb and block the sound waves generated by the printer’s motors, fans, and vibrations. This section will guide you through common material options, their properties, and important considerations for safety and budget.Effectively reducing noise requires understanding the acoustic properties of different materials. Factors such as density, porosity, and thickness play a significant role in how well a material can absorb or block sound.

We will explore materials commonly used in acoustic treatments and how they apply to the specific environment of a 3D printer enclosure.

Common Sound-Absorbing Materials for 3D Printer Enclosures

A variety of materials can be employed to dampen the sound produced by your 3D printer. These materials are typically categorized by their acoustic performance, with higher density and specific cellular structures often indicating better sound absorption.

- Acoustic Foam: This is a popular choice due to its excellent sound absorption properties, especially for mid to high frequencies. Its open-cell structure effectively traps sound waves, converting them into heat. Different profiles, such as egg crate or pyramid shapes, increase the surface area for even better absorption.

- Mass-Loaded Vinyl (MLV): MLV is a dense, flexible barrier material that excels at blocking sound transmission, particularly low frequencies. It’s often used as a decoupling layer or in conjunction with absorptive materials to create a composite soundproofing solution.

- Rubber Mats: Thick rubber mats, such as those used for gym floors or vibration dampening, can be effective in reducing structural vibrations and blocking sound. Their density helps to absorb impact noise and low-frequency rumble.

- Mineral Wool or Fiberglass Insulation: While typically used in building construction, these materials offer excellent sound absorption. When used within an enclosure, they must be properly contained to prevent fiber release and ensure fire safety.

- Closed-Cell Foam: Unlike open-cell acoustic foam, closed-cell foam is denser and less porous. While not as effective at absorbing airborne sound as open-cell foam, it can be useful for blocking vibrations and providing some degree of sound isolation.

Material Properties: Absorption Coefficients and Density

The effectiveness of a soundproofing material is often quantified by its sound absorption coefficient (SAC), which ranges from 0 (perfect reflection) to 1 (perfect absorption). Density is another critical factor, with heavier materials generally being better at blocking sound.

| Material | Typical Density (kg/m³) | Sound Absorption Coefficient (SAC)

|

Primary Use |

|---|---|---|---|

| Acoustic Foam (e.g., Polyurethane) | 20-60 | 0.6 – 0.9 | Sound absorption, reducing echo and reverberation |

| Mass-Loaded Vinyl (MLV) | 6000 – 12000 | 0.1 – 0.3 (as a barrier) | Sound blocking, reducing transmission |

| Rubber Mats (e.g., EPDM) | 800 – 1500 | 0.3 – 0.6 | Vibration dampening, some sound absorption |

| Mineral Wool/Fiberglass Insulation | 30 – 100 | 0.7 – 1.0 | High-level sound absorption, requires containment |

It’s important to note that absorption coefficients can vary significantly based on the specific product, thickness, and the frequency of the sound being measured. Materials with higher density, like MLV, are more effective at blocking sound, while porous materials like acoustic foam excel at absorbing it.

A combination of both types of materials often yields the best results.

Fire Safety Considerations for Enclosure Materials

When selecting materials for the interior of a 3D printer enclosure, fire safety is a critical concern. 3D printers operate at elevated temperatures, and any flammable materials in close proximity pose a significant risk.

Materials used inside a 3D printer enclosure should ideally be fire-retardant or non-combustible. Always check manufacturer specifications for fire ratings.

Acoustic foams are available with varying fire retardant treatments. Look for foams that are specifically rated for fire resistance, often referred to as Class A or Class B fire ratings. Similarly, if considering insulation materials, ensure they have been treated for fire resistance. Mass-loaded vinyl is generally considered to have good fire resistance, but it’s always prudent to verify the specific product’s fire rating.

Avoid materials that are easily ignited or produce toxic fumes when burned.

Cost-Effective Material Options

Balancing effectiveness with budget is often a key consideration for DIY projects. Fortunately, there are several cost-effective options for soundproofing your 3D printer enclosure.

- DIY Acoustic Foam Panels: Purchasing large, uncut sheets of acoustic foam and cutting them to size yourself can be more economical than buying pre-cut panels.

- Recycled Materials: Thick rubber mats salvaged from old gym equipment or industrial applications can be a very affordable source of vibration dampening.

- Dense Cardboard or MDF with Insulation: While not as effective as dedicated acoustic materials, layers of dense cardboard or thin MDF can be used to create a barrier. These can then be lined with a more affordable, yet effective, absorptive material like mineral wool (properly contained within a fabric or plastic liner) to create a composite sound-dampening layer.

- Bulk Purchase: Buying soundproofing materials in larger quantities, especially from online retailers or specialty acoustic suppliers, can often lead to significant cost savings per unit.

For instance, a roll of basic acoustic foam might cost significantly less per square foot than smaller, specialized kits. Similarly, sourcing used but still functional rubber mats can drastically reduce the expense associated with vibration dampening. When evaluating cost-effectiveness, consider the long-term benefits of noise reduction and the overall lifespan of the materials.

Designing and Building a Soundproofed Enclosure

Creating an effective soundproof enclosure for your 3D printer involves thoughtful design and careful construction. The goal is to build a barrier that not only contains the printer’s noise but also absorbs and dampens the sound waves effectively. This section will guide you through the principles of designing such an enclosure and the practical steps involved in its construction.A well-designed enclosure will typically employ a multi-layered approach to soundproofing.

This strategy leverages different materials with varying acoustic properties to tackle sound transmission and reflection. By combining these layers, you can significantly reduce the perceived noise levels emanating from your 3D printer, creating a more peaceful working or living environment.

Designing a Multi-Layered Enclosure Structure

The effectiveness of a soundproof enclosure hinges on its structural design. A multi-layered approach is paramount, as it allows for the combination of different soundproofing principles. Each layer serves a specific purpose, contributing to the overall reduction of noise.A common and effective multi-layered design incorporates the following components:

- Structural Frame: This forms the skeleton of the enclosure, providing rigidity and support for the other layers. Materials like wood (MDF, plywood) or aluminum extrusions are suitable.

- Inner Damping Layer: This layer is applied directly to the inner surfaces of the structural frame. Its primary function is to absorb sound energy.

- Mass Loaded Vinyl (MLV) or Dense Barrier Layer: This is a heavy, dense material that acts as a barrier to sound transmission. It is crucial for blocking airborne sound.

- Outer Absorption Layer: This layer is applied to the exterior of the MLV or barrier layer. It helps to absorb any sound that might reflect back from the inner surfaces or escape through small gaps.

- Acoustic Sealant: Used to fill any gaps or seams between layers and at the enclosure’s edges to prevent sound leakage.

The thickness and composition of each layer can be adjusted based on the desired level of sound reduction and the available space. For instance, thicker MLV will provide better sound blocking, while thicker acoustic foam will offer superior sound absorption.

Applying Soundproofing Materials to Interior Surfaces

Once the basic structure of your enclosure is in place, the next critical step is the meticulous application of soundproofing materials to its interior surfaces. This is where the bulk of the sound absorption and dampening occurs.The interior of the enclosure is the first line of defense against the noise generated by the 3D printer. Therefore, ensuring complete coverage with appropriate materials is essential for maximizing the soundproofing effectiveness.Here’s a detailed process for applying soundproofing materials:

- Prepare the Interior Surfaces: Ensure the interior surfaces of your enclosure are clean, dry, and free from dust or debris. This will allow for optimal adhesion of the soundproofing materials.

- Cut Materials to Size: Carefully measure the interior surfaces of your enclosure (walls, ceiling, floor, and door) and cut your chosen soundproofing materials (e.g., acoustic foam, mass-loaded vinyl) to fit these dimensions precisely.

- Apply Adhesive: Use a strong, appropriate adhesive for the materials you are using. Spray adhesives, contact cement, or specialized acoustic adhesives are common choices. Apply the adhesive evenly to both the surface of the enclosure and the back of the soundproofing material, following the manufacturer’s instructions.

- Install Damping Material (e.g., MLV): If you are using a dense barrier like Mass Loaded Vinyl, install it first. Ensure it is laid flat and covers the entire surface without any wrinkles or gaps. Overlap seams by a few inches and seal them with acoustic sealant for maximum effectiveness.

- Install Absorption Material (e.g., Acoustic Foam): After the barrier layer, apply your acoustic foam or other absorption materials. These are typically placed over the MLV or directly onto the structural frame if MLV is not used. Ensure good contact and cover all available surfaces.

- Consider Ventilation and Cable Management: While covering surfaces, plan for ventilation openings and cable passthroughs. These areas require special attention to ensure they do not become sound leaks.

The aim is to create a continuous, unbroken surface of sound-absorbing and sound-blocking materials within the enclosure.

Sealing Gaps and Seams to Prevent Sound Leakage

Even with carefully applied soundproofing materials, small gaps and seams can act as significant pathways for sound to escape. Therefore, meticulously sealing these areas is as crucial as the material application itself. Sound, much like water, will find the path of least resistance.Effective sealing ensures that the sound waves are contained within the enclosure and are absorbed or dampened by the materials, rather than leaking out into your environment.Methods for sealing gaps and seams include:

- Acoustic Sealant/Caulk: This is a flexible, non-hardening sealant specifically designed for acoustic applications. It remains pliable and can absorb vibrations, making it ideal for filling cracks, joints, and edges. Apply a generous bead of acoustic sealant to all seams, corners, and around any openings.

- Weather Stripping: For doors and access panels, high-density foam or rubber weather stripping can create an airtight seal when the panel is closed. Ensure the stripping is compressed sufficiently to form a good seal.

- Gaskets: Similar to weather stripping, gaskets can be used around access points or fan housings to create a tight seal.

- Tape: While not as effective as sealant for long-term solutions, heavy-duty acoustic tape can be used to temporarily seal minor gaps during the construction process or for very small, non-critical areas.

Pay close attention to areas where different materials meet, where panels are joined, and around any penetrations for power cords, USB cables, or ventilation. A thorough inspection and sealing process will significantly enhance the overall soundproofing performance of your enclosure.

Step-by-Step Guide for Constructing a Basic Soundproof Enclosure

Constructing a soundproof enclosure can be approached systematically. This guide Artikels the steps for building a basic, effective enclosure suitable for most desktop 3D printers. Materials Needed:

- Plywood or MDF sheets (e.g., 1/2 inch or 3/4 inch thick)

- Wood screws

- Hinges and a latch for the door

- Mass Loaded Vinyl (MLV)

- Acoustic foam panels

- Acoustic sealant

- Weather stripping

- Optional: Ventilation fans and filters

Construction Steps:

- Plan Your Dimensions: Measure your 3D printer and determine the internal dimensions required for the enclosure, allowing for adequate space around the printer for ventilation and access.

- Cut Wood Panels: Cut your plywood or MDF into the required sizes for the base, back, sides, top, and door of the enclosure.

- Assemble the Box: Construct the main body of the enclosure by screwing the base, back, and side panels together. Ensure all joints are square and secure.

- Prepare the Door: Cut out the door panel. Install hinges on one side and a latch on the opposite side to allow for easy access.

- Apply Interior Damping: Cut MLV to fit the interior surfaces of the enclosure walls, ceiling, and floor. Adhere it securely using appropriate adhesive. Overlap seams and seal them with acoustic sealant.

- Apply Interior Absorption: Cut acoustic foam panels to cover the MLV. Adhere these panels to the MLV, ensuring complete coverage.

- Seal the Door: Apply weather stripping around the perimeter of the door opening. This will create a seal when the door is closed.

- Install the Door: Attach the door to the enclosure using the hinges and ensure the latch engages properly to create a tight seal.

- Seal All Seams: Go over all internal and external seams, corners, and edges with acoustic sealant to ensure there are no sound leaks.

- Add Ventilation (Optional but Recommended): If ventilation fans are to be installed, create openings for them. Line the edges of these openings with acoustic foam and ensure fans are mounted securely and sealed to prevent air and sound leakage. Consider using baffled ventilation designs for better sound isolation.

- Final Inspection: Thoroughly inspect the entire enclosure for any gaps or potential sound leakage points. Reapply sealant or weather stripping as needed.

This step-by-step process will result in a functional and significantly quieter 3D printing experience.

Integrating Soundproofing into Existing Enclosures

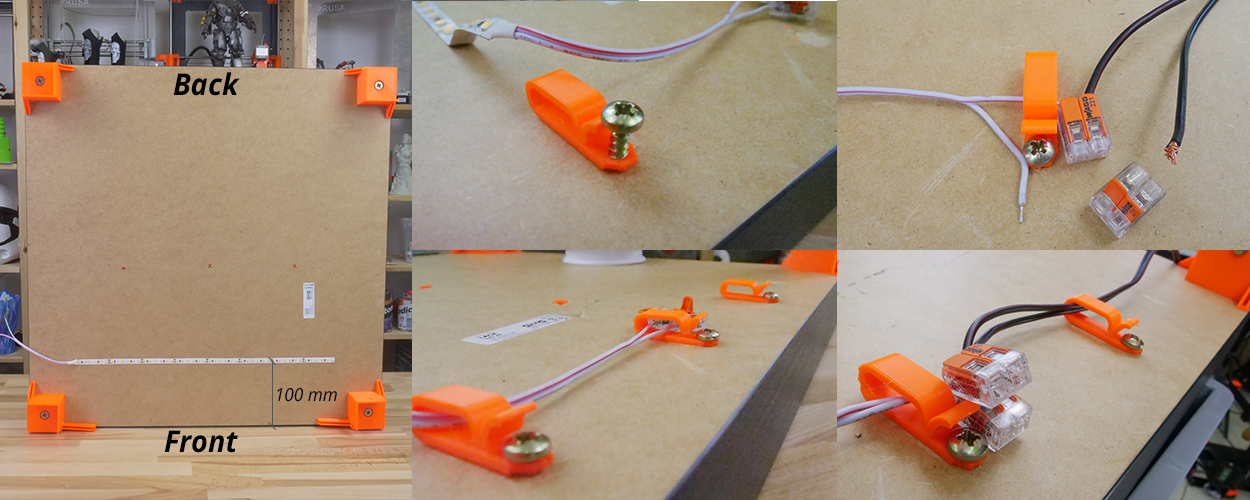

![[DIY] 3D Printer Enclosure - Page 1 [DIY] 3D Printer Enclosure - Page 1](https://howbanget.web.id/wp-content/uploads/2025/09/9_59c835e4-aae6-4865-a387-0a31894e255b.jpg)

Retrofitting soundproofing into an existing 3D printer enclosure presents a unique set of challenges and opportunities. While you may not have the luxury of designing from scratch, there are effective strategies to significantly reduce noise without requiring a complete rebuild. This section will guide you through the practical steps of enhancing the acoustic performance of your current setup.

Retrofitting Sound Dampening Materials

The primary goal when retrofitting is to add sound-absorbing and sound-blocking materials to the interior surfaces of your enclosure. This involves carefully selecting materials that are effective against the frequencies generated by your 3D printer and then finding ways to securely attach them. Common areas to target include the walls, ceiling, and even the floor of the enclosure, as these are the primary surfaces where sound waves will reflect and emanate.

Attaching Soundproofing Layers

Securing soundproofing materials to an existing enclosure requires a balance between firm adhesion and preserving the enclosure’s structural integrity. The chosen method should prevent the materials from shifting or falling, which could interfere with the printer’s operation or create new rattling noises.Here are practical methods for attaching soundproofing layers:

- Adhesive Backing: Many acoustic foam panels and mass-loaded vinyl (MLV) come with pre-applied, high-strength adhesive. Ensure the enclosure surfaces are clean and dry before application for optimal adhesion. This method is straightforward and often provides a secure bond without the need for additional hardware.

- Spray Adhesives: For materials that do not have pre-applied adhesive, a strong spray adhesive can be a viable option. It allows for even coverage across larger areas and can bond effectively to various surfaces. Always use these adhesives in a well-ventilated area and follow the manufacturer’s safety guidelines.

- Mechanical Fasteners: In some cases, particularly with heavier materials like MLV or dense foam, mechanical fasteners such as screws or rivets might be necessary. To maintain structural integrity, it’s crucial to use these sparingly and in locations that won’t weaken the enclosure. Consider using washers to distribute the load and prevent tearing of the material.

- Velcro Strips: For removable panels or sections, industrial-strength Velcro strips offer a flexible attachment solution. This is particularly useful if you anticipate needing to access internal components or clean the enclosure regularly. Ensure the Velcro is applied to both the enclosure and the soundproofing material securely.

- Clips or Brackets: Custom-designed or off-the-shelf clips and brackets can be employed to hold soundproofing panels in place. This method is less invasive than drilling but may require some modification to the enclosure’s existing frame.

Maintaining Airflow and Ventilation

One of the most critical considerations when adding soundproofing to an existing enclosure is ensuring that adequate airflow and ventilation are maintained. 3D printers generate heat, and without proper ventilation, components can overheat, leading to print failures or damage to the printer.Key aspects to consider for airflow:

- Ventilation Openings: Do not completely seal off any existing ventilation openings. If possible, try to integrate soundproofing materials around these openings rather than directly over them.

- Sound Baffles for Vents: For ventilation ports, consider creating baffled pathways using sound-absorbing materials. This involves creating a labyrinthine path that allows air to flow through while forcing sound waves to bounce off absorbent surfaces, thus reducing noise transmission.

- Fan Placement: If you are adding active cooling for the electronics or enclosure, ensure the fans are positioned to draw in fresh air and exhaust hot air effectively. Soundproofing materials should not obstruct the fan blades or airflow path.

- Temperature Monitoring: After retrofitting, closely monitor the internal temperature of your enclosure during printing. If temperatures rise significantly, you may need to reassess your soundproofing strategy or consider adding a dedicated ventilation fan.

Effectiveness of Different Attachment Methods

The method used to attach soundproofing materials can influence their effectiveness and longevity. A poorly attached layer may vibrate or detach, negating its sound-dampening properties and potentially causing new noises.Here’s a comparison of the effectiveness of different attachment methods:

| Attachment Method | Effectiveness for Soundproofing | Considerations |

|---|---|---|

| Adhesive Backing | High, when applied correctly to clean surfaces. Ensures a solid contact for vibration damping and sound absorption. | Surface preparation is crucial. Can be difficult to reposition or remove without damage. |

| Spray Adhesives | Good, provides even coverage and strong bonding. | Requires ventilation during application. Potential for overspray. |

| Mechanical Fasteners | Excellent for heavy materials, provides very secure attachment. | Can compromise structural integrity if not used judiciously. May create small air gaps if not sealed. |

| Velcro Strips | Moderate, provides good adhesion but can allow for some vibration transfer if not high-quality. | Ideal for removable panels. May not be suitable for permanently sealing an enclosure. |

| Clips or Brackets | Variable, depends on the design and fit. Can be very effective if they hold the material flush against the surface. | May require custom fabrication or modification to the enclosure. |

Optimizing Ventilation and Airflow with Soundproofing

Integrating soundproofing into your 3D printer enclosure, while effectively reducing noise, can inadvertently impact its internal thermal environment. The very materials that block sound waves can also impede the free movement of air, leading to increased temperatures. Therefore, a well-designed ventilation system is crucial to maintain optimal printing conditions without compromising on noise reduction.A successful soundproofed enclosure requires a careful balance between thermal management and acoustic isolation.

The goal is to create pathways for air to enter and exit the enclosure that are acoustically treated, allowing for efficient cooling while preventing sound from escaping. This involves strategic placement of vents and the use of specialized components designed to attenuate noise.

Impact of Soundproofing on Internal Temperatures

Soundproofing materials, such as dense foams, mass-loaded vinyl, and fiberglass, are effective at absorbing and blocking sound energy. However, these materials also possess thermal insulation properties. When applied to the interior surfaces of an enclosure, they can trap heat generated by the 3D printer’s components, including the hotend, heated bed, and stepper motors. This trapped heat can lead to elevated internal temperatures, which may negatively affect print quality, cause filament to soften prematurely, or even lead to component overheating and premature failure.

For instance, a printer that typically operates at an internal enclosure temperature of 30°C might see this rise to 45°C or higher after significant soundproofing if ventilation is not addressed.

Designing a Noise-Minimizing Ventilation System

Creating an effective ventilation system for a soundproofed enclosure involves several key considerations. The primary objective is to facilitate sufficient airflow for cooling without allowing noise to propagate through the vent openings. This often means incorporating elements that force sound to take a longer, more convoluted path, thus reducing its intensity. The placement of intake and exhaust vents is also critical; positioning them on opposite sides of the enclosure can help create a more uniform airflow pattern and prevent stagnant air pockets.

Utilizing Baffled Vents and Sound-Attenuating Ducting

Baffled vents, also known as labyrinth vents or sound mazes, are a cornerstone of effective acoustic ventilation. These vents are designed with internal structures that create a tortuous path for air. Sound waves entering the vent are forced to bounce off multiple surfaces, losing energy with each reflection, before reaching the outside. This significantly reduces the amount of noise that can escape.Sound-attenuating ducting, often lined with acoustic foam, serves a similar purpose when longer air pathways are needed, such as for connecting an exhaust fan to an exterior vent.

The lining absorbs sound within the duct, preventing it from traveling along the air path.Here are some common methods and considerations for designing these systems:

- Baffled Vent Construction: This can be achieved by creating internal dividers or channels within the vent opening. A common DIY approach involves cutting a series of slots in two pieces of material and overlapping them to create a zig-zag path for air.

- Acoustic Foam Lining: For ducts, use foam specifically designed for acoustic absorption. Ensure the foam is fire-retardant and suitable for the operating temperatures within the enclosure.

- Fan Selection: Opt for quieter fans, often rated in decibels (dB). Consider using variable speed fans that can be adjusted based on internal temperature readings.

- Airflow Calculation: Estimate the required airflow (often measured in cubic feet per minute, CFM) based on the heat output of your printer components. Online calculators and printer manufacturer specifications can provide guidance.

- Placement Strategy: Position intake vents lower in the enclosure and exhaust vents higher to promote natural convection, which aids cooling.

Best Practices for Balancing Sound Reduction and Thermal Management

Achieving an optimal balance between sound reduction and thermal management requires a systematic approach. It is essential to monitor internal temperatures closely and adjust ventilation as needed.A comprehensive set of best practices includes:

- Initial Temperature Monitoring: Before implementing significant soundproofing, establish baseline internal enclosure temperatures during typical printing cycles.

- Phased Soundproofing Implementation: Apply soundproofing materials incrementally, monitoring temperature changes after each phase. This allows for identification of critical points where ventilation needs enhancement.

- Ventilation Integration During Design: If building a new enclosure, incorporate baffled vents and potential fan mounting points from the outset. Plan for clear air pathways.

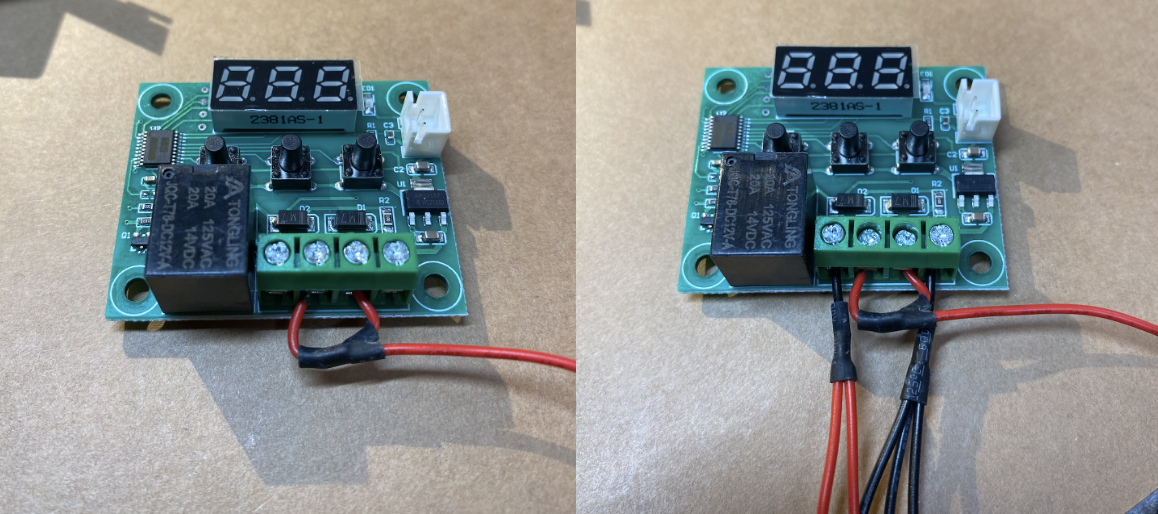

- Active Cooling Solutions: For enclosures that experience significant heat buildup, consider incorporating small, quiet fans for active intake or exhaust. These fans should ideally be placed within or near acoustically treated vent paths.

- Temperature-Sensing Control: Implement a thermostat or temperature sensor connected to a fan controller. This system can automatically activate or adjust fan speed based on the internal enclosure temperature, ensuring cooling only when necessary.

- Regular Airflow Checks: Periodically inspect vents and fans for dust buildup or obstructions, which can impede airflow and reduce cooling efficiency.

- Material Selection for Ventilation: When constructing baffled vents or ducting, choose materials that are rigid enough to maintain their shape and are non-porous to prevent sound leakage.

By carefully considering these design principles and best practices, you can create a 3D printer enclosure that is both significantly quieter and maintains optimal operating temperatures for high-quality prints.

Advanced Soundproofing Techniques

While basic soundproofing can significantly reduce noise, several advanced techniques can elevate your 3D printer enclosure’s acoustic performance to near silence. These methods focus on tackling vibrations at their source and optimizing the enclosure’s structural integrity for maximum sound isolation.These techniques often involve more specialized materials and construction methods, but the results are well worth the effort for those seeking the quietest possible printing environment.

Constrained Layer Damping for Panel Vibrations

Panel vibrations are a common source of noise in 3D printer enclosures, especially with larger or thinner panels. Constrained layer damping (CLD) is a highly effective method for mitigating these vibrations by introducing a viscoelastic material between two constraining layers. This setup dissipates vibrational energy as heat.The principle behind CLD is to shear the viscoelastic layer when the outer layers move.

This shearing action generates internal friction within the viscoelastic material, converting the mechanical energy of vibration into thermal energy.A typical CLD application involves adhering a layer of viscoelastic material, such as specialized damping mats or butyl rubber, to the inside surface of an enclosure panel. This is then followed by a rigid constraining layer, often a thin sheet of metal (like aluminum) or a hard plastic.

The viscoelastic layer should be thin and well-bonded to both the panel and the constraining layer for maximum effectiveness. The key is the shear deformation that occurs within the viscoelastic layer.

Isolating the Printer from its Base with Vibration-Damping Feet

The vibrations generated by the 3D printer’s motors and movement systems can travel through the printer’s frame and directly into the surface it rests upon. This transmission of vibrations can then radiate as sound into the surrounding environment. Isolating the printer from its base is crucial for preventing this.Vibration-damping feet, also known as isolation pads or anti-vibration mounts, are designed to absorb and dissipate these vibrations before they can be transmitted.

They work by introducing a compliant material between the printer’s chassis and the supporting surface.

When selecting vibration-damping feet, consider the following:

- Material: Common materials include dense rubber, neoprene, sorbothane, or specialized viscoelastic polymers. The material’s density and elasticity are key to its damping capabilities.

- Load Capacity: Ensure the feet can support the weight of your 3D printer without excessive compression. Overly compressed feet lose their damping effectiveness.

- Size and Shape: The feet should provide sufficient surface area for stable contact with both the printer and the base.

- Attachment Method: Some feet are adhesive, while others may require screws or bolts.

A common and effective setup involves placing the printer directly onto a dense, non-resonant mat (like a thick rubber mat or a piece of MDF) and then placing the vibration-damping feet underneath the printer’s own feet or directly on the printer’s base if it has a flat bottom. This creates a multi-stage isolation system.

Double-Pane Windows or Sound-Isolating Glass for Enclosure Visibility

Maintaining visibility into the enclosure is often desired to monitor print progress. However, standard acrylic or glass panels can act as sound conduits. Utilizing double-pane windows or specialized sound-isolating glass can dramatically reduce sound transmission while preserving clear views.Double-pane windows, similar to those used in residential construction, consist of two panes of glass separated by a sealed air gap or a gas-filled cavity.

The air gap acts as an acoustic barrier, significantly reducing sound transfer. For even greater effectiveness, the air gap can be filled with inert gases like argon, which have better sound-insulating properties than air.Sound-isolating glass, often referred to as acoustic glass, takes this a step further. It typically involves laminating a viscoelastic interlayer, such as polyvinyl butyral (PVB), between two or more panes of glass.

This laminated structure is highly effective at dampening sound vibrations.

When considering these options for your enclosure:

- Thickness: Thicker glass generally offers better sound insulation.

- Air Gap Width: For double-pane windows, a wider air gap (typically 1/2 inch or more) provides better performance.

- Lamination: Acoustic glass with a viscoelastic interlayer is superior to simple double-pane construction for sound isolation.

- Sealing: Ensure all edges are perfectly sealed to prevent sound leaks.

For a DIY approach, consider using two separate acrylic or glass panels with a substantial air gap between them, carefully sealed around the edges.

Custom-Fit Soundproofing Panels for Specific Enclosure Designs

Off-the-shelf soundproofing solutions may not always perfectly fit unique or custom-designed 3D printer enclosures. Creating custom-fit panels allows for precise application of soundproofing materials, ensuring no gaps or compromises in acoustic performance. This approach maximizes the effectiveness of your soundproofing efforts.The process involves carefully measuring the internal dimensions of your enclosure and then cutting soundproofing materials to match these exact specifications.

This ensures a snug fit, minimizing any potential pathways for sound to escape.

Here’s a guide to creating custom-fit soundproofing panels:

- Measure Precisely: Use a tape measure or digital caliper to get accurate dimensions of each internal panel of your enclosure (walls, roof, door). Account for any internal components or obstructions.

- Select Your Materials: Choose the soundproofing materials you wish to use. This could include acoustic foam, mass-loaded vinyl (MLV), damping mats, or a combination. Consider the acoustic properties needed for each surface.

- Create Templates: For complex shapes, it’s often helpful to create paper or cardboard templates first. Cut these templates to fit the exact contours of the enclosure’s interior.

- Cut Materials to Size: Lay your chosen soundproofing material flat and use the templates or your precise measurements to mark and cut the material. Use sharp utility knives, scissors, or specialized cutting tools depending on the material.

- Apply Adhesives (if necessary): If you are adhering the panels directly to the enclosure walls, use an appropriate adhesive. Spray adhesives, construction adhesives, or double-sided acoustic tape are common choices. Ensure the adhesive is compatible with both the enclosure material and the soundproofing material.

- Install Panels: Carefully press the custom-fit panels into place, ensuring a tight seal against the enclosure walls. For removable panels, consider using Velcro strips or small clips.

- Address Gaps: Pay close attention to any small gaps or seams. These can be sealed with acoustic caulk or specialized gap fillers to further enhance sound isolation.

This meticulous approach ensures that every surface of your enclosure contributes to sound reduction, leading to a significantly quieter printing experience.

Evaluating the Effectiveness of Soundproofing

Once you’ve invested time and resources into designing and building a soundproofed enclosure for your 3D printer, the next crucial step is to objectively assess how well your efforts have paid off. This evaluation ensures that your enclosure is performing as intended, minimizing printer noise and creating a more pleasant printing environment. This section will guide you through the methods for quantifying sound reduction and subjectively assessing the noise levels.

Measuring Sound Reduction in Decibels

Quantifying sound reduction provides objective data on the effectiveness of your soundproofing. The standard unit for measuring sound intensity is the decibel (dB). By taking measurements before and after soundproofing, you can determine the precise dB reduction achieved. This process typically involves using a sound level meter, also known as a decibel meter.To conduct accurate measurements, ensure the sound level meter is calibrated and placed at a consistent distance from the 3D printer, both with and without the enclosure.

It is advisable to take readings during a typical printing cycle that produces a consistent level of noise, such as a long print with significant infill. Recording the ambient noise level in your workspace without the printer running is also essential for establishing a baseline.

The formula for sound reduction (SR) in decibels is: SR (dB) = L1 – L2, where L1 is the sound level without the enclosure and L2 is the sound level with the enclosure.

A significant reduction in decibels indicates effective soundproofing. For example, a reduction of 10 dB is generally perceived as halving the loudness of the sound, while a 20 dB reduction is perceived as four times quieter.

Conducting Subjective Listening Tests

While decibel measurements offer objective data, subjective listening tests are equally important for evaluating the perceived quietness of your soundproofed enclosure. This method relies on human perception and can reveal subtle noise characteristics that might not be fully captured by a sound level meter.To conduct a subjective listening test, have individuals unfamiliar with the soundproofing project listen to the printer operating inside the enclosure.

Ask them to describe the noise level and quality. Specific questions to guide their assessment include:

- Is the printer’s noise noticeable when you are in the same room?

- Can you hold a conversation comfortably while the printer is running?

- Does the noise disrupt other activities, such as watching television or working?

- Are there any specific types of noise (e.g., fan whine, motor vibrations) that are still prominent?

It’s beneficial to have multiple individuals perform these tests to gather a range of opinions. Their feedback, combined with your own observations, provides a holistic view of the enclosure’s acoustic performance.

Identifying Remaining Noise Sources

Even with effective soundproofing, some residual noise may persist. Identifying these remaining sources is crucial for further refinement and optimization of your enclosure. This step requires careful observation and sometimes the use of additional diagnostic tools.Begin by listening intently to the printer while it’s enclosed and operating. Try to isolate the distinct sounds. Common culprits for residual noise include:

- Vibrations transmitted through the printer’s frame or the enclosure’s base.

- Air leaks around doors, vents, or cable passthroughs.

- High-frequency fan noise that may still penetrate some materials.

- Resonances within the enclosure itself, amplifying certain frequencies.

Tactile examination can also be helpful. Gently touch different parts of the enclosure and the printer while it’s running to feel for vibrations. A stethoscope or even a length of hose can be used to pinpoint the origin of specific sounds by directing them to your ear.

Comprehensive Soundproofing Evaluation Checklist

To ensure a thorough evaluation of your 3D printer enclosure’s soundproofing effectiveness, use the following checklist. This checklist combines objective measurements with subjective assessments and detailed inspection.

| Evaluation Area | Method | Assessment Criteria | Notes |

|---|---|---|---|

| Objective Noise Measurement | Sound Level Meter (dB) | Compare pre- and post-soundproofing readings. Aim for a significant dB reduction (e.g., 10-20 dB or more). | Ensure consistent distance and printing conditions. |

| Subjective Noise Perception | Listening Tests (multiple individuals) | Assess comfort for conversation, disruption of other activities. | Gather feedback on specific noise types. |

| Vibration Transmission | Tactile Inspection | Feel for vibrations on enclosure walls, base, and printer components. | Use a stethoscope or hose for pinpointing. |

| Air Leak Detection | Visual Inspection and Smoke/Incense Test | Check seals around doors, vents, and cable entries for any air currents or visible gaps. | A smoke test can highlight subtle leaks. |

| Material Integrity | Visual Inspection | Ensure all soundproofing materials are securely in place and free from damage. | Check for any loose panels or gaps. |

| Ventilation Effectiveness | Temperature and Airflow Monitoring | Verify that internal temperatures remain within acceptable limits and airflow is adequate. | Ensure soundproofing has not compromised cooling. |

| Overall Acoustic Quality | Holistic Listening Assessment | Evaluate the general quietness and pleasantness of the printing environment. | Consider the perceived reduction in annoyance. |

Conclusive Thoughts

In conclusion, by understanding the principles of sound absorption and blocking, carefully selecting appropriate materials, and implementing thoughtful design and construction techniques, you can transform your 3D printer from a noisy contraption into a remarkably quiet operation. Whether you are retrofitting an existing enclosure or building a new one, these strategies will lead to a significantly more serene printing environment, allowing you to focus on your creations without the distracting din.