Embarking on the exciting journey of 3D printing can seem daunting at first, but understanding the fundamental steps to selecting your first machine is crucial for a rewarding experience. This guide aims to demystify the process, offering clear insights and practical advice to help you navigate the world of 3D printers with confidence.

From assessing your personal needs and project aspirations to understanding the different technologies available, we will explore the essential features that make a 3D printer beginner-friendly. We will also delve into material considerations, the setup process, and the software that brings your digital designs to life, ensuring you have a comprehensive overview before making your purchase.

Understanding Your Needs and Goals

Embarking on the journey of 3D printing as a beginner can be both exciting and a little daunting. The vast array of printers and their capabilities can make choosing the right one a significant first step. To navigate this effectively, it’s crucial to first understand what you intend to achieve with your new device. This foundational understanding will guide your decisions and ensure you select a printer that aligns with your aspirations and current skill level.The path to selecting a 3D printer is paved with self-reflection and an honest assessment of your intended use.

What you want to print will fundamentally shape the type of printer, its features, and even its cost. Considering common beginner projects can illuminate the practical requirements of 3D printing and help you envision your own creative endeavors.

Common Beginner Projects Influencing Printer Choice

Many newcomers to 3D printing start with projects that are relatively straightforward yet demonstrate the power and versatility of the technology. These projects often serve as excellent learning tools and can highlight the importance of certain printer features.Here are some popular starting points for aspiring 3D printer owners:

- Figurines and Miniatures: Printing small, detailed models for hobbies like tabletop gaming or collecting. This often requires a printer with good resolution and the ability to handle intricate details.

- Functional Household Items: Creating practical objects such as custom tool holders, organizers, replacement parts for appliances, or even unique kitchen gadgets. Durability and material compatibility are key considerations here.

- Educational Models: Printing anatomical models, geometric shapes, or prototypes for science and engineering projects. Accuracy and the ability to print with specific educational materials might be important.

- Simple Decorative Objects: Designing and printing small vases, planters, or decorative accents for your home. Aesthetics and ease of post-processing are often prioritized.

- Prototyping Simple Designs: For those with an interest in invention or engineering, printing early-stage prototypes of simple mechanical parts or conceptual models. Precision and repeatability are vital.

Key Questions for Beginner 3D Printer Selection

Before you even begin browsing specific models, asking yourself a few critical questions will significantly streamline your search and prevent potential buyer’s remorse. These questions focus on your personal circumstances and expectations.Consider the following inquiries to clarify your requirements:

- What is the primary purpose for which I want a 3D printer? (e.g., hobby, education, small business prototyping)

- What types of materials do I envision using? (e.g., PLA, ABS, PETG, flexible filaments)

- What level of detail and accuracy do I need in my prints?

- How much space do I have available for the printer and its operation?

- What is my technical comfort level with electronics and software?

- Am I looking for a plug-and-play experience or am I willing to tinker and learn more about the mechanics?

Defining Your Budget

Budget is a paramount factor that will heavily influence your choices. The world of 3D printers spans a wide price spectrum, from very affordable entry-level machines to professional-grade industrial units. For beginners, establishing a realistic budget upfront is essential to narrow down options and avoid overspending or purchasing a printer that is too basic to meet your needs.It is important to recognize that the initial purchase price is not the only cost associated with 3D printing.

Beyond the printer itself, you will need to factor in the cost of materials (filament), potential upgrades or replacement parts, tools for post-processing (like sanding or painting), and possibly software.Consider the following budget breakdown:

- Entry-Level ($200 – $500): These printers are ideal for absolute beginners who want to experiment with the technology. They typically offer basic functionality and are great for learning the fundamentals. Expect to print with common materials like PLA and potentially encounter a steeper learning curve for calibration and troubleshooting.

- Mid-Range ($500 – $1000): This category often provides a better balance of features, build quality, and ease of use. Printers in this range may offer larger build volumes, more advanced features like auto-bed leveling, and better reliability, allowing for a wider range of materials and more complex prints.

- Higher-End Entry ($1000+): While still considered beginner-friendly, printers in this range offer significant advantages such as superior print quality, faster printing speeds, advanced safety features, and robust build materials. They are suitable for those who are serious about investing in the hobby or have specific demanding projects in mind.

When setting your budget, it is prudent to allocate an additional 10-20% for filament, tools, and unexpected accessories to ensure a smoother initial experience.

Types of 3D Printers for Beginners

Selecting the right 3D printer can feel like navigating a maze, especially for newcomers. The two most prevalent technologies for entry-level users are Fused Deposition Modeling (FDM) and Resin (SLA/DLP) printing. Each offers distinct advantages and disadvantages, influencing everything from print quality and material options to cost and ease of use. Understanding these differences is crucial for making an informed decision that aligns with your initial projects and learning curve.This section will delve into the core characteristics of FDM and Resin printers, highlighting their suitability for beginners by examining their operational principles, material compatibility, build volumes, and overall user experience.

Fused Deposition Modeling (FDM) Printers

FDM printers are the workhorses of the hobbyist and entry-level 3D printing world. They operate by extruding molten thermoplastic filament layer by layer onto a build platform. This process is analogous to a hot glue gun precisely drawing out shapes. The filament, typically wound on a spool, is fed through a heated nozzle that melts it, and then deposited according to the digital model’s instructions.

Pros and Cons of FDM for Beginners

FDM printers are often recommended for beginners due to their accessibility, affordability, and versatility. However, they do come with certain trade-offs.

- Pros:

- Cost-Effective: Entry-level FDM printers are generally more affordable than their resin counterparts. Filament materials are also relatively inexpensive.

- Ease of Use: Many FDM printers come pre-assembled or with straightforward assembly instructions. The printing process is generally less messy and requires less specialized ventilation compared to resin printing.

- Material Variety: FDM printers can work with a wide array of thermoplastic filaments, including PLA, ABS, PETG, and TPU, each offering different properties like strength, flexibility, and temperature resistance.

- Larger Build Volumes: Typically, FDM printers offer larger build volumes at lower price points, allowing for the printing of bigger objects or multiple smaller items simultaneously.

- Durability: Prints from FDM printers are generally more robust and less brittle than resin prints, making them suitable for functional parts and prototypes.

- Cons:

- Print Resolution: FDM prints can exhibit visible layer lines, resulting in a less smooth surface finish compared to resin prints. Achieving highly detailed or intricate models may require significant post-processing.

- Print Speed: FDM printing can be slower, especially for larger or more complex models, as the nozzle has to traverse the entire layer before moving to the next.

- Warping and Adhesion Issues: Some materials, like ABS, are prone to warping if the build plate temperature is not maintained correctly, and print adhesion can sometimes be a challenge.

- Support Structures: Overhanging parts often require support structures, which can be difficult to remove cleanly and may leave marks on the finished print.

Typical Build Volumes for Entry-Level FDM Printers

Entry-level FDM printers commonly feature build volumes ranging from approximately 150 x 150 x 150 mm (6 x 6 x 6 inches) to 220 x 220 x 250 mm (8.7 x 8.7 x 9.8 inches). Some popular beginner models might offer slightly larger capacities, such as 300 x 300 x 300 mm (11.8 x 11.8 x 11.8 inches), providing ample space for a wide variety of projects, from small figurines to larger household items.

Material Compatibility of Common Beginner FDM Printers

The most common and beginner-friendly filament for FDM printers is Polylactic Acid (PLA). It is easy to print with, has minimal warping, and is biodegradable. Other common materials include:

- ABS (Acrylonitrile Butadiene Styrene): Stronger and more heat-resistant than PLA, but requires higher print temperatures and good ventilation due to fumes.

- PETG (Polyethylene Terephthalate Glycol): Offers a good balance of strength, flexibility, and ease of printing, often considered a step up from PLA.

- TPU (Thermoplastic Polyurethane): A flexible filament ideal for creating rubber-like parts, though it can be more challenging to print.

Most entry-level FDM printers are designed to handle PLA and PETG with ease, while ABS and TPU may require specific printer settings or upgrades.

Resin (SLA/DLP) Printers

Resin 3D printers, including Stereolithography (SLA) and Digital Light Processing (DLP) technologies, utilize liquid photopolymer resin that hardens when exposed to a specific wavelength of light. SLA printers use a UV laser to trace each layer, while DLP printers use a digital projector to cure an entire layer at once. This light-curing process allows for exceptionally high detail and smooth surface finishes.

Pros and Cons of Resin for Beginners

Resin printing offers superior detail but comes with a steeper learning curve and additional considerations regarding safety and post-processing.

- Pros:

- Exceptional Detail and Smoothness: Resin printers excel at producing highly detailed and smooth surfaces, making them ideal for miniatures, jewelry, and intricate prototypes where fine features are paramount.

- High Resolution: The layer heights in resin printing are typically much smaller than in FDM, resulting in incredibly fine details and a near-photorealistic finish.

- Faster for Small, Detailed Objects: While large prints can be slow, resin printers can be faster than FDM for printing many small, detailed objects simultaneously on the build plate.

- Cons:

- Cost: Resin printers and their associated materials (resins) are generally more expensive than FDM printers and filaments.

- Messy and Odorous: Liquid resins can be messy to handle, and many have strong, unpleasant odors. Proper ventilation and personal protective equipment (gloves, masks) are essential.

- Post-Processing: Prints require washing in isopropyl alcohol or a specialized cleaner to remove uncured resin, followed by curing under UV light to achieve full strength. This adds significant steps to the printing workflow.

- Material Limitations: While a variety of resins exist (standard, tough, flexible, castable), the material options are more limited and specialized compared to FDM filaments.

- Smaller Build Volumes: Entry-level resin printers typically have smaller build volumes, often in the range of 120 x 68 x 150 mm (4.7 x 2.7 x 5.9 inches) to 192 x 120 x 200 mm (7.5 x 4.7 x 7.9 inches), limiting the size of objects that can be printed in one piece.

- Brittleness: Many standard resins can be brittle, making prints susceptible to breaking if dropped or subjected to stress.

Typical Build Volumes for Entry-Level Resin Printers

Beginner resin printers usually offer smaller build volumes, often in the range of 120 x 68 x 150 mm (4.7 x 2.7 x 5.9 inches) for smaller desktop models, up to around 192 x 120 x 200 mm (7.5 x 4.7 x 7.9 inches) for slightly larger, but still entry-level, units. This size is well-suited for printing miniatures, small prototypes, or jewelry components.

Material Compatibility of Common Beginner Resin Printers

The primary material for SLA/DLP printers is photopolymer resin. Beginners typically start with:

- Standard Resins: These are general-purpose resins offering good detail and a balance of properties, available in various colors.

- Tough Resins: Designed to be more impact-resistant and less brittle than standard resins, suitable for functional parts.

- ABS-Like Resins: Mimic the mechanical properties of ABS plastic, offering increased strength and durability.

It is crucial to use resins specifically formulated for your printer’s UV wavelength (e.g., 405nm is common) to ensure proper curing and optimal print results.

Key Features to Look For

As a beginner embarking on your 3D printing journey, selecting a printer with user-friendly features can significantly ease the learning curve and lead to more successful prints. Focusing on these essential aspects will help you avoid common frustrations and build confidence.This section will delve into the critical features that make a 3D printer accessible and enjoyable for newcomers, ensuring a smoother and more rewarding experience from your very first print.

Automatic Bed Leveling

Achieving a perfectly level print bed is paramount for successful 3D printing, as it ensures the first layer adheres properly and subsequent layers build evenly. Manual bed leveling can be a tedious and frustrating process for beginners, often requiring multiple adjustments and test prints. Automatic bed leveling systems, however, take the guesswork out of this crucial step.These systems utilize sensors to measure the distance between the nozzle and the print bed at various points.

The printer’s firmware then compensates for any unevenness by adjusting the Z-axis height during the printing process.

“A perfectly calibrated print bed is the foundation of a great 3D print.”

The benefits of auto-bed leveling for beginners are substantial:

- Reduced Setup Time: Eliminates the need for manual calibration before each print.

- Improved Print Success Rates: Significantly increases the likelihood of the first layer adhering correctly, preventing failed prints.

- Less Frustration: Removes a common source of stress and confusion for new users.

- Consistent Results: Ensures a uniform gap between the nozzle and bed across the entire build surface, leading to more uniform prints.

Filament Runout Sensors and Power Loss Recovery

These two features are invaluable safety nets for beginners, preventing the loss of hours of printing time due to unexpected interruptions.A filament runout sensor detects when the spool of filament is nearing its end or has broken. Upon detection, it pauses the print and alerts the user, allowing them to replace the filament without compromising the print. This is especially helpful for longer prints where filament changes might otherwise go unnoticed until it’s too late.

Power loss recovery (also known as resume print functionality) is equally critical. In the event of a power outage or accidental unplugging, the printer can save its current position and resume printing from where it left off once power is restored. This feature can save beginners from the heartbreak of a print being ruined by a simple power flicker.

Open-Source vs. Proprietary Ecosystems

The choice between an open-source and a proprietary ecosystem can significantly impact a beginner’s experience with software, hardware upgrades, and community support. Open-Source Ecosystems are characterized by their transparency and community-driven development.

- Software: Typically utilize open-source slicing software like Cura or PrusaSlicer, which are powerful, feature-rich, and constantly updated by a global community of developers.

- Hardware: Often use readily available components, making repairs and upgrades more accessible and potentially more affordable.

- Community Support: Benefit from vast online communities, forums, and wikis where users share knowledge, troubleshoot problems, and offer advice. This is invaluable for beginners seeking help.

- Flexibility: Offer greater freedom to experiment with different filaments, modifications, and advanced techniques as skills develop.

Proprietary Ecosystems, on the other hand, are controlled by a single manufacturer.

- Software: May come with their own proprietary slicing software, which can be simpler to use initially but might offer less flexibility or advanced features compared to open-source options.

- Hardware: Components might be specific to the manufacturer, potentially making repairs or upgrades more challenging and expensive.

- Support: Often provide dedicated customer support, which can be beneficial for beginners who prefer direct assistance.

- Ease of Use: Manufacturers may design their printers and software to be highly integrated and user-friendly out-of-the-box.

For beginners, an open-source ecosystem often provides a richer learning environment with abundant community resources, which can be more beneficial than a more closed, proprietary system.

User-Friendly Software Interfaces

The software used to prepare 3D models for printing, known as slicing software, plays a crucial role in the overall user experience. For beginners, a user-friendly interface is essential for understanding the printing process and achieving good results.Key aspects of user-friendly slicing software include:

- Intuitive Layout: Clear organization of menus, settings, and tools that are easy to navigate.

- Pre-set Profiles: Optimized settings for common printer models and filament types that allow beginners to start printing quickly without deep technical knowledge.

- Visual Feedback: The ability to preview the sliced model layer by layer, visualize supports, and estimate print time and material usage.

- Simplified Settings: While advanced settings are important, beginner modes or guided wizards can help new users avoid overwhelming complexity.

- Clear Explanations: Tooltips or integrated help systems that explain the function of different settings and their impact on the print.

Popular open-source slicers like Cura and PrusaSlicer excel in this regard, offering both beginner-friendly modes and advanced customization options as users gain experience. The ability to easily adjust parameters like layer height, infill density, and print speed, and then see the immediate impact on the estimated print time and material consumption, is incredibly empowering for a new user.

Filament and Resin Considerations

Choosing the right printing material is as crucial as selecting the printer itself, as it directly impacts the quality, durability, and application of your 3D prints. For beginners, understanding the common types of filaments and the specific handling requirements of resins will significantly enhance your 3D printing journey. This section will guide you through these essential material considerations.

Printer Assembly and Setup

Once you’ve chosen the perfect 3D printer for your beginner journey, the next crucial step is bringing it to life through assembly and setup. This process, while sometimes appearing daunting, is designed to be straightforward, especially with beginner-focused models. A well-assembled and calibrated printer is the foundation for successful and enjoyable 3D printing.The assembly process for most beginner 3D printers typically involves connecting a few pre-assembled modules.

These printers are often designed with modularity in mind, meaning major components like the gantry, base, and control panel come largely put together. Your role will usually be to connect these parts using provided screws and cables, following a clear, step-by-step guide. This approach minimizes the need for specialized tools and technical expertise, making it accessible to individuals with little to no prior mechanical experience.

Typical Assembly Process

Beginner-friendly 3D printers are engineered for ease of assembly. The goal is to get you printing as quickly and as smoothly as possible.The assembly generally follows a logical progression:

- Base and Frame: You will likely start by attaching the main frame components to the printer’s base. This might involve screwing together vertical supports and connecting them to the stable bottom platform.

- Gantry System: The print head’s movement system, known as the gantry, is usually a significant pre-assembled unit. This will be attached to the frame, ensuring it moves freely along its designated axes (X and Y).

- Z-Axis Rods: The vertical movement (Z-axis) is typically controlled by threaded rods. These are inserted into their respective mounts on the frame, allowing the print bed or the gantry to move up and down.

- Control Panel and Wiring: The LCD screen and control knob are usually attached to the front or side of the printer. You’ll then connect a few ribbon cables from the control panel to the main control board, ensuring they are plugged in the correct orientation.

- Print Bed Installation: The print bed, where your creations will be built, is then mounted onto its carriage. This might involve screws or clips, depending on the printer model.

Common Setup Steps

After the physical assembly is complete, the focus shifts to configuring the printer’s software and ensuring its mechanical components are aligned. This calibration is vital for print quality and success.Key setup steps include:

- Firmware Initialization: For some printers, you might need to ensure the correct firmware is loaded. Most beginner printers come pre-loaded, but it’s good practice to check the manual.

- Axis Calibration: This ensures that the printer moves the correct distance when commanded. It’s usually handled by the firmware, but understanding its importance is key.

- Bed Leveling: This is arguably the most critical step for initial print success. The print bed must be perfectly level relative to the nozzle. Most printers have an auto-leveling feature, or a manual process involving adjusting screws under the bed while using a piece of paper to gauge the distance between the nozzle and the bed at various points.

- Extruder Calibration (E-steps): This process ensures that the extruder motor pushes out the correct amount of filament. While often pre-calibrated, it’s a setting you might fine-tune later.

- Initial Test Prints: Once calibrated, it’s time to perform a test print. This is usually a small, simple model like a calibration cube or a small figurine. This print will reveal any issues with leveling, adhesion, or movement.

Importance of the User Manual

The user manual is your most valuable companion during the initial stages of 3D printer ownership. It’s not just a formality; it’s a comprehensive guide tailored to your specific model.

The user manual is the definitive source of information for your 3D printer. Skipping it is akin to navigating a new city without a map.

The manual provides:

- Detailed, step-by-step assembly instructions with diagrams specific to your printer.

- Information on recommended tools and their usage.

- Troubleshooting guides for common issues encountered during setup.

- Specifications and limitations of your printer.

- Guidance on software installation and initial configuration.

- Basic maintenance schedules and procedures.

Familiarizing yourself with the manual before and during assembly will prevent many potential frustrations and ensure you understand the capabilities and requirements of your new device.

Basic Maintenance for a New 3D Printer

Even a brand-new 3D printer benefits from immediate attention to basic maintenance to ensure longevity and optimal performance. These are simple tasks that don’t require specialized knowledge but contribute significantly to the printer’s health.The initial maintenance steps focus on ensuring smooth operation and preventing wear:

- Lubrication: Check the user manual for recommended lubrication points on the printer’s moving parts, such as the Z-axis rods or linear rails. Apply a small amount of the specified lubricant (often grease or oil) to ensure smooth movement and reduce friction.

- Tightening Screws and Belts: After initial assembly and during the first few prints, it’s wise to gently re-check that all screws are snug. Vibrations from operation can cause them to loosen slightly. Similarly, ensure that any drive belts are properly tensioned – not too loose to slip, and not too tight to cause undue strain.

- Nozzle Cleaning: Before your very first print, and periodically afterward, ensure the nozzle is clean and free of any debris. A small brush or a specialized nozzle cleaning tool can be used.

- Bed Surface Inspection: Check the print bed for any residue or imperfections that could affect first layer adhesion. Clean it according to the manufacturer’s recommendations (e.g., with isopropyl alcohol).

Initial Printer Setup and First Print Success Checklist

To ensure a smooth transition from unboxing to successful printing, follow this checklist. It covers the essential steps to get your beginner 3D printer ready for its first masterpiece.

- Unboxing and Inventory: Carefully unpack all components and compare them against the packing list in the manual to ensure everything is present and undamaged.

- Assembly Completion: Follow the user manual meticulously for physical assembly. Double-check all connections and ensure parts are securely fastened.

- Tool Check: Confirm you have the necessary tools as specified in the manual (often included, but sometimes requiring basic household tools).

- Power Connection: Connect the power cable and ensure the power switch is in the off position before plugging it in.

- Initial Power-On: Turn on the printer and observe if the screen lights up and the fans spin. Listen for any unusual noises.

- Firmware Verification: Confirm the correct firmware version is loaded, as indicated in the manual.

- Bed Leveling Procedure: Perform the bed leveling process (manual or automatic) until the nozzle is at the correct height across the entire print surface.

- Test Print Preparation: Load a small, pre-sliced test model (often provided on an SD card or downloadable from the manufacturer’s website) onto the printer.

- Filament Loading: Load your chosen filament according to the manual’s instructions. Ensure it feeds smoothly into the extruder.

- First Print Initiation: Start the test print and monitor the first layer closely. This is the most critical stage for adhesion.

- Print Monitoring: Stay nearby during the initial stages of the print to address any immediate issues like warping or layer shifting.

- Post-Print Inspection: Once the print is complete, allow it to cool before removing it from the build plate. Inspect the print for quality and accuracy.

Software and Slicing

The journey from a digital 3D model to a physical object is facilitated by specialized software. This crucial step bridges the gap between your design or downloaded file and the precise instructions your 3D printer needs to execute. Understanding this software is key to achieving successful and high-quality prints.Slicing software, often referred to as a “slicer,” takes a 3D model (typically in formats like .STL or .OBJ) and divides it into hundreds or thousands of thin, horizontal layers.

For each layer, it generates the specific toolpath the printer’s nozzle or laser will follow. This process also allows you to define numerous print settings that directly influence the final outcome, such as print speed, layer height, infill density, and support structures.

The Role of Slicing Software

Slicing software is indispensable for 3D printing. It translates the three-dimensional geometry of a digital model into a series of two-dimensional instructions, known as G-code. This G-code is the universal language that 3D printers understand, dictating every movement of the print head, extruder temperature, bed temperature, and fan speed. Without a slicer, a 3D printer would have no way of knowing how to build an object layer by layer.

The slicer essentially acts as the interpreter between your design and the printer’s capabilities.

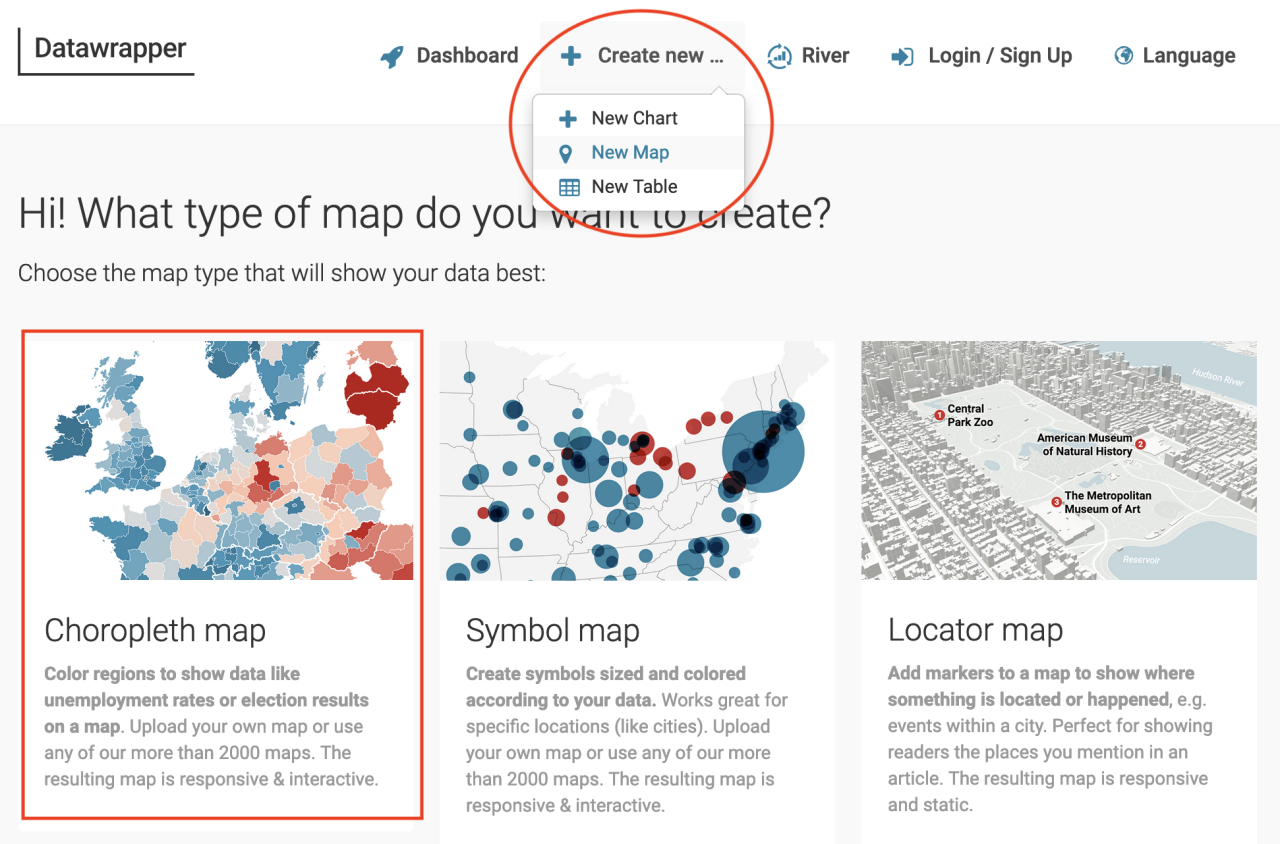

Popular Beginner-Friendly Slicing Applications

Several slicing programs are well-suited for beginners due to their intuitive interfaces and robust feature sets. These applications often come with pre-configured profiles for common 3D printers, simplifying the initial setup process.

- Cura: Developed by Ultimaker, Cura is one of the most popular and widely used slicers. It boasts a user-friendly interface, extensive customization options, and a large community for support. It’s compatible with a vast array of 3D printers.

- PrusaSlicer: Originally developed for Prusa Research printers, PrusaSlicer is now open-source and supports many other printer brands. It is known for its advanced features, excellent print quality, and intuitive workflow, making it a strong contender for beginners.

- Creality Slicer: If you own a Creality printer, their proprietary slicer offers a streamlined experience tailored to their hardware. It’s often bundled with their printers and provides a straightforward entry point into slicing.

Core Slicing Software Settings for Beginners

While slicing software offers a plethora of settings, beginners should focus on understanding a few key parameters that have the most significant impact on print quality and success. Mastering these will provide a solid foundation for troubleshooting and improving prints.

Layer Height

This setting determines the thickness of each individual layer the printer deposits. A smaller layer height (e.g., 0.1mm) results in finer detail and smoother surfaces but increases print time. A larger layer height (e.g., 0.3mm) prints faster but with more visible layer lines.

Infill

Infill refers to the internal structure printed within an object to provide support and strength. It’s usually expressed as a percentage. Higher infill percentages lead to stronger, heavier, and more material-intensive prints. For most functional prints, 15-25% infill is sufficient. For decorative items, lower percentages or even 0% infill might be acceptable.

Common infill patterns include grid, cubic, and gyroid.

Print Speed

This setting dictates how fast the printer’s nozzle moves while extruding filament. Printing too fast can lead to poor layer adhesion, stringing, and dimensional inaccuracies. Printing too slowly can waste time and potentially cause overheating of the nozzle. Beginners should start with the default recommended speeds for their printer and filament.

Supports

When a model has overhangs or bridges that extend too far without any material below them, the slicer can generate temporary support structures. These supports are printed alongside the model and are designed to be removed after printing. Choosing the right support type (e.g., normal, tree) and density is crucial for preventing print failures due to unsupported sections collapsing.

Adhesion

Print bed adhesion is critical for ensuring the first layer sticks properly to the print surface. Slicers offer options like skirts, brims, and rafts to help with this.

- Skirt: A few lines printed around the model’s base, helping to prime the nozzle and ensure filament flow before the actual print begins.

- Brim: A single layer of material printed around the base of the object, increasing the contact area with the print bed and improving adhesion, especially for models with small footprints.

- Raft: A thicker, multi-layer base printed beneath the model, providing a stable foundation for prints that are prone to warping or have very poor bed adhesion.

Finding and Downloading 3D Models

The vast majority of beginners will start by printing existing 3D models rather than designing their own. Fortunately, the online 3D printing community has created an extensive library of free and paid models.

- Thingiverse: A popular and free repository with a massive collection of user-uploaded 3D models. It’s an excellent starting point for finding almost anything you can imagine.

- MyMiniFactory: This platform curates high-quality, tested 3D printable models, often from professional designers. It offers both free and paid options.

- Cults3D: A marketplace for 3D printable models, featuring a wide range of designs from independent creators. You’ll find both free and premium models here.

- Printables.com: Similar to Thingiverse, Printables.com is a rapidly growing platform offering a vast selection of free 3D models with an emphasis on community interaction and design challenges.

When searching for models, use descriptive s and check the comments and makes section to see how the model has printed for others.

Workflow: From Download to Print

A typical workflow for taking a downloaded 3D model and preparing it for printing is straightforward once you understand the steps involved.

- Download the 3D Model: Find a model you like from one of the repositories mentioned above and download the file, usually in .STL or .OBJ format.

- Open the Model in Slicer Software: Launch your chosen slicing software (e.g., Cura, PrusaSlicer) and import the downloaded 3D model file.

- Orient and Scale the Model: Position the model on the virtual print bed for optimal printing. Sometimes, rotating the model can reduce the need for supports or improve print quality. You can also scale the model to your desired size if the original dimensions are not suitable.

- Adjust Print Settings: Select a print profile for your specific 3D printer and filament type. Then, review and adjust the core settings discussed earlier (layer height, infill, print speed, supports, adhesion) based on the model’s complexity and your desired outcome. For beginners, starting with default or recommended settings is a good practice.

- Slice the Model: Once you are satisfied with the settings, click the “Slice” button. The software will process the model and generate the G-code file.

- Preview the Sliced Model: Most slicers offer a preview mode that allows you to examine the generated layers, toolpaths, and support structures. This is a critical step to catch potential issues before committing to a print.

- Save the G-code: Save the generated G-code file to an SD card or transfer it directly to your 3D printer via USB, depending on your printer’s connectivity options.

- Start the Print: Load your chosen filament, ensure your print bed is clean and level, and then select the G-code file on your 3D printer to begin the printing process.

Community and Support

Embarking on your 3D printing journey can be incredibly rewarding, but it’s also natural to encounter questions and challenges along the way. Fortunately, the 3D printing world is rich with vibrant communities and readily available support systems that can significantly ease your learning curve and help you overcome any hurdles. Engaging with these resources can transform potential frustrations into valuable learning experiences.The collective knowledge and shared experiences within the 3D printing community are invaluable for beginners.

From troubleshooting intricate print failures to discovering advanced techniques, fellow makers are often the best resource. Manufacturers also play a crucial role in providing official support, ensuring that your initial interactions with your new printer are as smooth as possible.

The Value of Online Communities and Forums

Online communities and forums serve as digital gathering spaces for 3D printing enthusiasts of all levels. These platforms allow beginners to ask questions, share their projects, and learn from the successes and failures of others. The sheer volume of shared information means that most common issues have likely been discussed and resolved, providing you with quick access to solutions.

Troubleshooting Common Printing Issues

When your prints don’t turn out as expected, understanding common issues and their solutions is paramount. These problems can range from layer adhesion failures to stringing and supports that are difficult to remove. Access to a community that has encountered and documented these issues can save you significant time and filament.Here are some frequently encountered printing problems and their general causes:

- Layer Adhesion Failure: This occurs when layers of the print do not bond properly, leading to weak or delaminated prints. Causes can include incorrect printing temperature, cooling too rapidly, or insufficient extrusion.

- Stringing/Oozing: Fine strands of filament left between parts of a print. This is often caused by filament being too hot, retraction settings being too low, or filament moisture.

- Warping: When the corners or edges of a print lift off the build plate. This is typically due to uneven cooling and the plastic contracting as it cools, especially on larger prints. Bed adhesion issues and insufficient bed temperature can contribute.

- Bed Adhesion Issues: When the first layer of the print doesn’t stick to the build plate. This can be caused by an uneven build surface, incorrect Z-offset, dirty build plate, or improper bed temperature.

- Over-extrusion/Under-extrusion: Extruding too much or too little filament. Over-extrusion can lead to blobs and poor surface finish, while under-extrusion results in gaps and weak prints.

Manufacturers Offering Strong Customer Support

When selecting your first 3D printer, consider manufacturers known for their robust customer support for entry-level machines. Good support can include readily available documentation, responsive customer service, and active online communities associated with the brand.Some manufacturers that are frequently praised for their beginner-friendly support include:

- Creality: Known for its vast community and extensive online resources, often providing prompt responses on forums and through their official channels.

- Anycubic: Offers dedicated customer service and a growing community presence, with many users sharing troubleshooting tips and modifications.

- Prusa Research: While often considered a mid-range to higher-end option, their commitment to open-source and excellent, detailed documentation and support makes them a great choice for those willing to invest a bit more.

Leveraging Tutorials and Guides for Learning New Techniques

Tutorials and guides are indispensable tools for beginners looking to expand their 3D printing knowledge. These resources can cover everything from basic printer operation and maintenance to advanced slicing techniques and post-processing methods. Following along with visual guides, especially video tutorials, can demystify complex processes and accelerate your learning.Topics commonly covered in tutorials include:

- Initial printer calibration and bed leveling.

- Understanding and adjusting slicer settings for different materials and print qualities.

- Basic maintenance tasks like cleaning the nozzle and lubricating moving parts.

- Tips for improving print success rates and aesthetics.

- Introduction to different filament types and their properties.

Essential Online Resources for Ongoing Learning

To foster continuous learning and stay updated with the latest in 3D printing, a curated list of online resources is highly beneficial. These platforms offer a wealth of information, from beginner guides to expert discussions and news.Here is a list of essential online resources for your 3D printing journey:

- Reddit Communities: Subreddits like r/3Dprinting, r/ender3, and r/prusa3d are incredibly active and provide a constant stream of user-generated content, troubleshooting advice, and project showcases.

- YouTube Channels: Many channels offer comprehensive video tutorials, printer reviews, and project guides. Popular channels include Thomas Sanladerer, Maker’s Muse, and Teaching Tech.

- Manufacturer Websites and Forums: Official websites often host knowledge bases, FAQs, and community forums where you can find direct support and connect with other users of the same printer.

- 3D Printing Blogs and Websites: Websites like All3DP, 3DPrint.com, and Hackaday provide news, reviews, tutorials, and project ideas relevant to all levels of 3D printing.

- Thingiverse, Printables, and Cults3D: While primarily repositories for 3D models, these sites often have active comment sections and forums where users discuss printing issues and share settings for specific models.

Conclusion

By carefully considering your objectives, understanding the available technologies, and focusing on user-friendly features, you can confidently select a 3D printer that perfectly suits your beginner needs. This guide has equipped you with the knowledge to navigate the exciting landscape of 3D printing, paving the way for countless creative projects and a fulfilling hobby.