Embarking on a new printing project, whether for personal crafting or professional endeavors, can feel like navigating uncharted territory. The very first test print often stands as a critical gateway, setting the stage for what’s to come and offering invaluable insights before significant resources are committed. Understanding and mastering this initial step is paramount to achieving desired outcomes efficiently and cost-effectively.

This comprehensive guide is meticulously designed to walk you through every facet of executing a successful first test print. From understanding its fundamental importance and conducting essential pre-print preparations to skillfully setting up your design, executing the print, and thoroughly evaluating the results, we cover it all. Furthermore, we equip you with robust troubleshooting techniques for common issues and strategies for optimizing settings for future endeavors, ensuring your journey into printing is both smooth and productive.

Understanding the Importance of a First Test Print

Embarking on any new project, whether it’s a complex architectural model, a custom-designed piece of furniture, or even a simple prototype, hinges on a critical initial step: the first test print. This foundational stage is far more than a mere formality; it is a strategic imperative that sets the tone for the entire production process, directly influencing the quality, efficiency, and ultimate success of your endeavor.

A well-executed test print acts as a crucial quality control checkpoint, providing invaluable insights before significant resources are committed.Failing to conduct a thorough test print, or worse, skipping it entirely, can lead to a cascade of problems that erode time, budget, and morale. These issues often manifest as costly errors discovered late in the production cycle, requiring extensive rework, material waste, and potential project delays.

The insights gained from a successful test print are instrumental in preventing these costly missteps, ensuring that your project progresses smoothly and meets its intended specifications from the outset.

Crucial Role in Project Validation

A successful first test print serves as the definitive validation of your design and its manufacturability. It is the moment where theoretical design meets tangible reality, allowing for immediate assessment of critical parameters that cannot be fully evaluated on screen. This physical manifestation provides concrete evidence of whether the design translates accurately into a reproducible object, identifying potential flaws or areas for refinement.

Mitigating Risks and Preventing Costly Errors

Skipping a test print is akin to navigating a complex maze blindfolded. The potential pitfalls are numerous and can have severe financial and temporal consequences. Without this initial validation, you risk discovering fundamental design flaws, material incompatibilities, or dimensional inaccuracies only after significant investment in materials and labor.Here are some of the key risks associated with neglecting a test print:

- Material Waste: Incorrect material selection or calibration can lead to unusable prints, wasting valuable raw materials and incurring significant replacement costs.

- Design Inaccuracies: Subtle errors in scaling, tolerances, or component fit can go unnoticed until later stages, requiring costly redesign and re-fabrication.

- Equipment Malfunction: A test print can reveal suboptimal machine settings or potential equipment issues before they affect a larger, more critical production run.

- Reduced Product Quality: Without initial validation, the final product may suffer from aesthetic imperfections, structural weaknesses, or functional deficiencies, leading to customer dissatisfaction.

- Project Delays: Discovering errors late in the process inevitably leads to rework, pushing back timelines and potentially incurring penalties or missed market opportunities.

Benefits of an Efficient Initial Print

Conversely, a well-executed first test print yields substantial benefits that ripple throughout the project lifecycle, contributing to overall efficiency and significant cost savings. It is an investment that pays dividends by streamlining the production process and ensuring a higher quality final output.The advantages of a successful initial print include:

- Early Problem Identification: Issues are detected and resolved when they are easiest and cheapest to fix, preventing escalation.

- Optimized Material Usage: Calibrating settings and confirming material suitability minimizes waste and ensures efficient use of resources.

- Accurate Cost Estimation: A successful test print provides a realistic benchmark for production time and material consumption, leading to more precise cost projections.

- Improved Design Iteration: The feedback from a test print allows for targeted design adjustments, leading to a more refined and robust final product.

- Increased Confidence: Successfully validating a design through a test print boosts confidence in the project’s viability and the team’s ability to execute.

A common example of this is in the field of additive manufacturing (3D printing). A company developing a new consumer electronic device might design a complex internal housing. Without a test print, they might discover after printing dozens of units that a specific mounting point is misaligned by a fraction of a millimeter, making it impossible to assemble the final product.

This would necessitate re-designing, re-printing all the housings, and potentially delaying the product launch by weeks, incurring significant costs for materials, labor, and lost revenue. A single, well-executed test print at the design stage would have identified this issue immediately, allowing for a quick design tweak and preventing all subsequent waste and delays.

Essential Preparations Before Printing

Embarking on your first test print is an exciting step, and thorough preparation is the cornerstone of a successful outcome. Before you even think about hitting the print button, dedicating time to gather the right materials, calibrate your equipment, and organize your workspace will significantly reduce the chances of errors and ensure you get the most valuable information from your test run.

This section will guide you through these crucial pre-print steps.A well-prepared approach not only streamlines the printing process but also helps you identify potential issues early on. Understanding what you need and how to set it up correctly will lay a solid foundation for interpreting your test print results accurately and making informed adjustments.

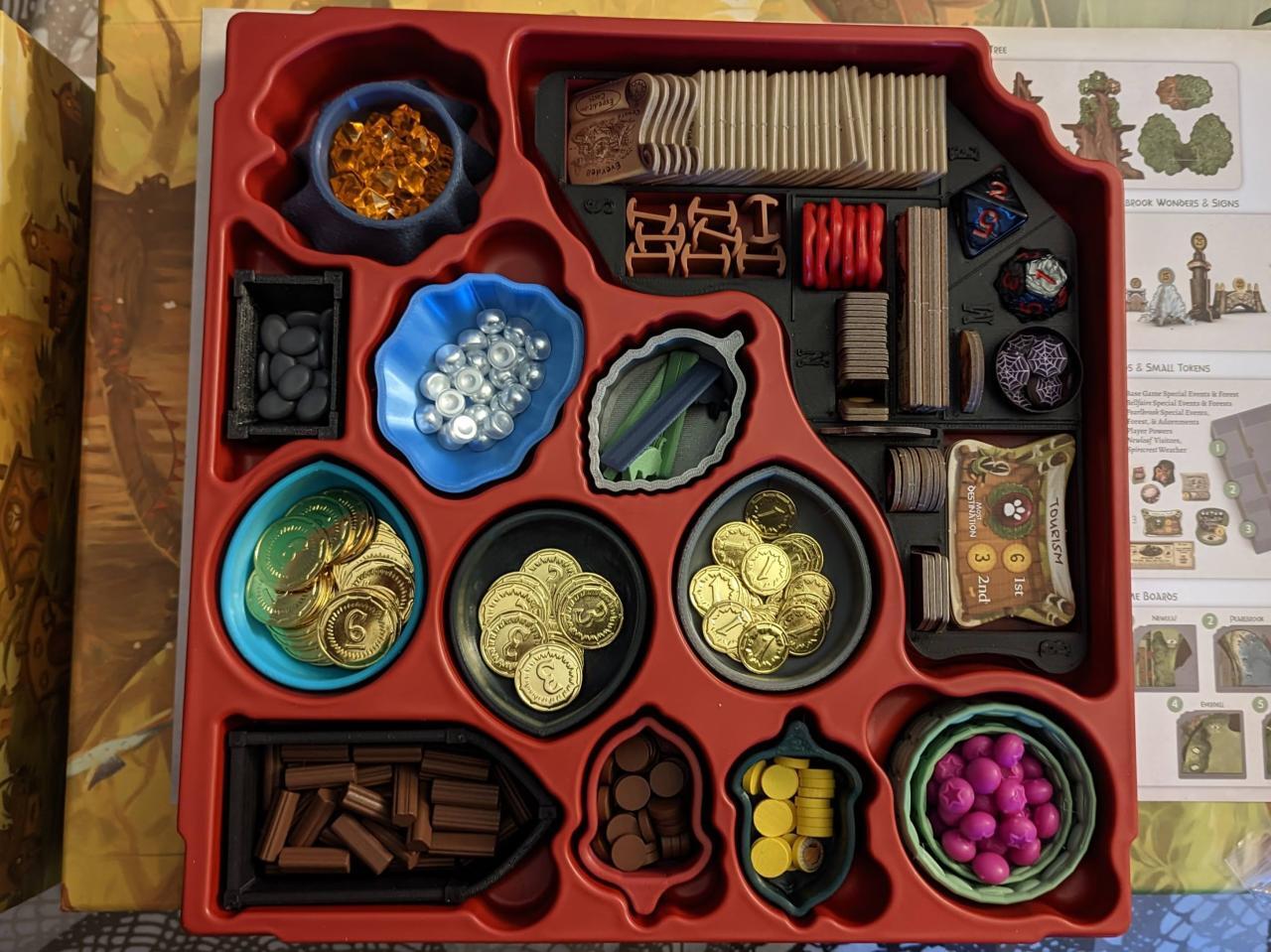

Key Materials and Tools for a Test Print

To ensure your test print yields the desired information and runs smoothly, having the correct materials and tools readily available is paramount. These items are not just for convenience; they are essential for accurate measurement, proper handling, and effective troubleshooting.The following list Artikels the primary components you will need:

- Printing Medium: This is the material your test print will be applied to. For a first test print, it’s often advisable to use the same type of material you intend to use for your final project. This could be paper of a specific weight and finish, cardstock, vinyl, fabric, or even a specialty material depending on your printer’s capabilities.

- Ink or Toner: Ensure you have sufficient ink or toner cartridges that are compatible with your printer and are not nearing depletion. Low ink levels can lead to incomplete prints and inaccurate color representation.

- Cleaning Supplies: Have on hand lint-free cloths, isopropyl alcohol (if recommended by your printer manufacturer for cleaning print heads or surfaces), and compressed air. These are vital for maintaining a clean printing environment and ensuring the print head or nozzle area is free from dust and debris.

- Measuring Tools: Depending on what you are testing, you may need a ruler, caliper, or measuring tape to verify dimensions, tolerances, or the accuracy of printed lines.

- Color Calibration Tools (Optional but Recommended): For color-critical prints, a spectrophotometer or colorimeter can be invaluable for measuring color accuracy and consistency.

- Utility Knife or Cutting Mat: If your test involves cutting or trimming the printed material, these will be necessary.

- Gloves: To prevent smudges and fingerprints on the printing medium, especially if it’s a delicate material or has a glossy finish.

Printer Calibration for Accurate Results

Before undertaking any printing, especially a test print intended to evaluate performance, calibrating your printing device is a non-negotiable step. Calibration ensures that the colors, dimensions, and overall output of your printer are as accurate and consistent as possible. Without proper calibration, the results of your test print may be misleading, leading to incorrect assumptions about your printer’s capabilities or your design’s fidelity.Calibration involves adjusting the printer’s settings to match a known standard or to compensate for variations in its hardware.

This process can significantly improve color reproduction, sharpness, and the faithfulness of your prints to the digital file.

“Accurate calibration is the bridge between your digital vision and the physical reality of your print.”

Most modern printers offer built-in calibration routines accessible through their software or control panel. These often involve printing a specific test pattern and then scanning it or inputting readings to guide the adjustment process. For advanced color accuracy, external calibration devices are used in conjunction with specialized software. Regularly performing these calibration steps, especially when changing ink, media, or after significant printer use, is a best practice for maintaining high-quality output.

Pre-Print Checklist for a Successful Run

A systematic checklist is your best ally in ensuring no critical step is overlooked before initiating a test print. This organized approach minimizes the risk of common errors and helps you focus on the specific objectives of your test. By ticking off each item, you build confidence that your printer is ready and your materials are prepared.Before you press ‘Print,’ take a moment to review the following essential checks:

- Software and Driver Updates: Confirm that your printer drivers and any associated printing software are up to date. Outdated software can sometimes cause compatibility issues or prevent optimal performance.

- Ink/Toner Levels: Verify that all ink or toner cartridges have sufficient levels. A low level in even one cartridge can compromise the entire print.

- Print Head/Nozzle Check: Most printers have a utility to check the print heads or nozzles. Run this test to ensure there are no clogs or missing lines in the pattern. If issues are detected, perform a cleaning cycle as recommended by your printer’s manual.

- Paper Type and Load: Ensure the correct paper type is selected in your printer settings to match the media loaded in the tray. Confirm that the paper is loaded correctly, aligned properly, and not overfilled.

- Print Quality Settings: Select the appropriate print quality settings for your test. For a first test print, you might opt for a high-quality setting to assess the printer’s best capabilities, or a draft setting if you are primarily checking for alignment and basic functionality.

- File Integrity: Double-check your test print file for any errors, incorrect formatting, or missing elements. Ensure it is saved in a compatible format.

- Printer Connection: Confirm that your printer is properly connected to your computer (via USB, network, or Wi-Fi) and is recognized by the operating system.

- Environmental Conditions: Ensure the printing environment is free from excessive dust, humidity, and extreme temperatures, which can affect print quality and the longevity of your printer.

Preparing Your Workspace for Printing

A dedicated and organized workspace is fundamental for a successful and efficient printing process, especially for test prints where careful observation and handling are key. A cluttered or unprepared area can lead to smudges, misplacements, and a general increase in the likelihood of errors. Setting up your space thoughtfully will create an environment conducive to accuracy and precision.Follow these steps to prepare your workspace:

- Clear the Surface: Ensure the surface where you will place your printer and handle your printed materials is clean, flat, and free of any debris. A smooth, uncluttered surface prevents accidental damage to prints and ensures stable placement of the printer.

- Organize Materials: Have all your necessary materials, such as printing medium, inks, cleaning supplies, and any tools, within easy reach. Arrange them logically so you can access them quickly without disturbing your printing setup.

- Lighting: Ensure adequate lighting in your workspace. Good lighting is crucial for inspecting prints for quality, color accuracy, and any defects. Natural light is often preferred, but a well-placed desk lamp can also be effective.

- Ventilation: If you are working with certain types of inks or materials that might emit fumes, ensure the area is well-ventilated. This is important for both your health and the quality of the print.

- Power Source: Make sure your printer and computer are connected to reliable power sources. Avoid using extension cords if possible, or ensure they are heavy-duty and rated for the equipment’s power draw.

- Waste Disposal: Have a designated area for waste materials, such as used cleaning cloths, scrap paper, or packaging. This helps maintain a tidy workspace throughout the printing process.

- Ergonomics: Position your printer and workspace so that you can operate the printer and handle the output comfortably, minimizing strain on your body.

Setting Up Your Design for a Test Print

Preparing your design file correctly is a crucial step in ensuring your test print accurately reflects your intended outcome. This involves understanding file formats, resolution, color management, and how these elements interact with your printer. A well-prepared file minimizes surprises and maximizes the effectiveness of your test print.This section will guide you through the essential considerations for setting up your design file, from formatting to selecting the right elements to test.

Design File Formatting for Printing

The format of your design file significantly impacts how it will be rendered by your printer. Choosing the right format ensures that elements are preserved, colors are represented accurately, and the overall print quality is maintained.Here are the recommended file formats and their benefits for test prints:

- PDF (Portable Document Format): This is often the preferred format for printing as it embeds fonts, images, and layout information, ensuring consistency across different devices and operating systems. It’s excellent for preserving vector graphics and high-resolution images.

- TIFF (Tagged Image File Format): A lossless image format that is ideal for high-quality photographic images. It supports various color depths and compression options, making it suitable for detailed graphics and photos.

- EPS (Encapsulated PostScript): Primarily used for vector graphics, EPS files can be scaled infinitely without losing quality. This is beneficial for logos, illustrations, and designs with sharp lines.

- AI (Adobe Illustrator): Native to Adobe Illustrator, this format is excellent for vector-based designs and allows for extensive editing. However, it may require specific software to open and print correctly.

Print Settings Best Practices

Selecting the appropriate print settings is paramount to achieving a representative test print. These settings dictate how your printer interprets and renders your digital design onto physical media.Consider the following settings for optimal results:

- Resolution: For most print applications, a resolution of 300 dots per inch (DPI) is considered standard for high-quality output. Lower resolutions can lead to pixelation and blurriness, especially in detailed areas. Ensure your design file’s resolution meets or exceeds this requirement for the intended print size.

- Color Profiles: Color management is critical. For professional printing, using the appropriate color profile is essential. Common profiles include:

- sRGB: A standard RGB color space, widely used for web and general digital display. It has a smaller color gamut than CMYK profiles.

- Adobe RGB (1998): Offers a wider color gamut than sRGB, making it suitable for professional photography and printing where a broader range of colors needs to be captured.

- CMYK (Cyan, Magenta, Yellow, Key/Black): This is the color model used in most commercial printing processes. Designing and proofing in a CMYK profile that matches your intended print method (e.g., SWOP, GRACoL) will provide the most accurate color representation.

When in doubt, consult with your print provider about their preferred color profile.

- Print Quality/Mode: Select the highest quality print setting available on your printer. This often corresponds to modes like “Best,” “Photo,” or a specific DPI setting that maximizes ink coverage and detail.

- Paper Type: Ensure the selected paper type in your printer settings matches the actual paper you are using. This allows the printer to optimize ink drying and application for that specific media.

Choosing the Right Test Pattern or Element to Print

The effectiveness of your test print hinges on selecting the right elements to evaluate. A well-chosen test pattern will reveal potential issues with color, detail, and overall rendering.Here are some key elements and patterns to consider for your test print:

- Color Swatches: Include a range of solid color swatches, from primary colors (red, green, blue, black, white) to secondary and tertiary colors. This helps assess color accuracy and saturation.

- Grayscale Gradient: A smooth transition from black to white is vital for evaluating tonal range and detecting banding issues, where smooth gradients appear as distinct steps.

- Text Samples: Print text in various sizes, weights (bold, regular), and fonts. This checks for legibility, sharpness, and any potential ink spread or fuzziness, especially in small font sizes.

- Fine Lines and Details: Incorporate thin lines, small geometric shapes, and intricate patterns to test the printer’s ability to reproduce fine details without bleeding or becoming indistinct.

- Photographic Elements: If your design includes photographs, print sections that contain highlights, mid-tones, and shadows to assess detail retention and dynamic range.

- Complex Graphics: Include elements with gradients, transparencies, and overlapping objects to see how the printer handles complex rendering and color blending.

A comprehensive test print should ideally incorporate a combination of these elements to provide a holistic view of your printer’s capabilities and your design’s fidelity.

Scaling and Orientation Considerations

The way your design is scaled and oriented on the print page is as important as the content itself. Incorrect scaling can distort your design, while improper orientation can lead to wasted material or misaligned prints.Key considerations include:

- Scaling: Ensure your design is scaled to the exact dimensions you intend for the final product. Avoid using “fit to page” options unless that is your specific goal, as this can inadvertently alter the aspect ratio. If you are testing a specific size, make sure your print driver settings reflect that size accurately. For example, if your design is intended to be 8×10 inches, set your print output size to 8×10 inches.

- Orientation: Pay close attention to the orientation of your design (portrait or landscape) and ensure it matches the orientation selected in your printer settings. A mismatch can result in a print that is rotated incorrectly or cropped unexpectedly.

- Bleed and Margins: If your design extends to the edge of the final print, ensure you have included a bleed area in your design file. This is an extra margin of color or image that extends beyond the trim line, preventing white edges after cutting. Also, consider the safe area for any critical text or graphics that should not be close to the trim edge.

For example, if you are printing a business card design that is 3.5 x 2 inches, and your design includes elements that go to the very edge, you would typically add a 0.125-inch bleed on all sides, making your design file 3.75 x 2.25 inches. When printing, you would select the correct paper size and ensure no scaling is applied that would reduce the bleed area.

Executing the First Test Print

With all the preparations meticulously completed, the moment to bring your design to life through a test print has arrived. This crucial step involves translating your digital blueprint into a physical manifestation, allowing for immediate assessment and refinement. Successfully executing this phase requires understanding the nuances of your printing device and maintaining vigilance throughout the process.This section will guide you through the practical steps of initiating and overseeing your first test print, ensuring a smooth and informative experience.

We will cover how to start the print, monitor its progress, address any emergent issues, and maintain optimal conditions for material handling and alignment.

Initiating a Test Print on Common Printing Devices

Starting a test print varies slightly depending on the type of printing device you are using, whether it’s a standard inkjet or laser printer for paper-based outputs, or a more specialized device like a 3D printer or a vinyl cutter. The core principle remains the same: sending a small, representative sample of your design to the printer.For most desktop printers (inkjet and laser):

- Open your design file in its respective software (e.g., Adobe Photoshop, Illustrator, Microsoft Word).

- Navigate to the “File” menu and select “Print.”

- In the print dialog box, choose your printer from the dropdown list.

- Select the option for “Test Page” or “Print a Sample” if available, or configure the print settings to print only a small section of your design, perhaps a single page or a designated area.

- Ensure the correct paper type and quality settings are selected to match your intended final print.

- Click “Print.”

For 3D printers:

- Load your sliced 3D model file (e.g., .STL, .3MF) onto the printer’s storage medium (SD card, USB drive) or send it via network.

- Select the file from the printer’s interface.

- Before initiating the full print, look for an option to “Preheat” the nozzle and bed to the required temperatures.

- Once heated, initiate a “Test Print” or “Preview Print” if your firmware supports it, which might print a small calibration cube or a specific section. If not, you may need to manually start the print and be ready to stop it after a few layers.

- Confirm the print initiation.

For vinyl cutters:

- Load your design into the cutting software (e.g., Cricut Design Space, Silhouette Studio).

- Ensure the correct blade and cutting mat are installed.

- Send a small portion of your design, or a designated test cut shape (like a small square or circle), to the cutter.

- Confirm the material is loaded correctly and aligned with the cutting mat.

- Initiate the cut.

Monitoring Print Progress and Identifying Early Signs of Issues

Once the print has begun, attentive observation is key to catching potential problems before they compromise the entire test print. This proactive monitoring allows for timely intervention, saving time and resources.Key indicators to watch for include:

- Material Feed: Observe how the paper, filament, or vinyl is being fed into the device. Look for any signs of buckling, jamming, or uneven feeding. For 3D printers, ensure the filament is extruding smoothly and consistently.

- Print Quality: Visually inspect the output as it is being produced. Are the colors accurate? Is the resolution as expected? Are there any streaks, smudges, gaps, or distorted lines?

- Alignment: For multi-layer prints or designs with precise positioning, check that each element is aligning correctly. In vinyl cutting, ensure the blade is cutting accurately within the design boundaries.

- Unusual Noises: Listen for any grinding, clicking, or unusual motor sounds that deviate from the normal operation of the printer. These can indicate mechanical issues.

- Software Feedback: Keep an eye on the printer’s display or the connected computer for any error messages or status updates.

Procedure for Handling Unexpected Errors During the Print

Encountering errors during a test print is not uncommon, especially with new setups or materials. Having a clear procedure in place will help you address these issues efficiently and minimize disruption.A systematic approach to error handling includes:

- Pause or Stop the Print: Immediately pause or stop the printing process once an error is detected. This prevents further damage or wasted material.

- Identify the Error: Refer to the printer’s manual or on-screen error codes to understand the specific problem. Common errors include paper jams, ink/toner issues, filament clogs, or motor failures.

- Consult Troubleshooting Guides: Utilize the manufacturer’s documentation, online forums, or support websites to find solutions for the identified error.

- Perform Necessary Corrections: This might involve clearing a paper jam, replacing an ink cartridge, unclogging a nozzle, or recalibrating a sensor. Ensure you follow safety guidelines, especially when dealing with heated components or moving parts.

- Reset and Retry: After making corrections, reset the printer if necessary and attempt to restart the test print, ideally from a point before the error occurred, if your software allows.

- Document the Issue: Note down the error, the steps taken to resolve it, and the outcome. This information is valuable for future reference and troubleshooting.

Tips for Ensuring Consistent Material Feed and Alignment

Maintaining consistent material feed and precise alignment are foundational to achieving accurate test prints. Deviations in these areas can lead to significant distortion and misinterpretation of your design’s fidelity.To ensure optimal performance:

- Material Handling:

- Store your printing materials (paper, filament, vinyl) in appropriate conditions to prevent warping, moisture absorption, or damage.

- Load materials carefully, ensuring they are centered and properly seated according to the printer’s guidelines.

- For 3D printing, ensure filament is wound neatly on the spool and does not tangle.

- For paper printers, use paper guides to keep the sheets aligned as they enter the printing path.

- Alignment Calibration:

- Regularly perform any built-in calibration routines your printer offers. This is particularly important for print head alignment in inkjet printers and bed leveling in 3D printers.

- For vinyl cutters, ensure the blade depth and offset are correctly set for the material being used.

- Check that the design is positioned correctly within the print area or on the cutting mat.

- Environmental Factors:

- Ensure the printer is placed on a stable, level surface. Vibrations can negatively impact print quality and alignment.

- Maintain a stable room temperature and humidity, as these can affect material properties, especially for 3D printing filaments.

Evaluating the Test Print Results

Once your first test print has been executed, the critical next step is a thorough evaluation. This process allows you to identify any deviations from your intended design and pinpoint potential issues that need addressing before committing to a full production run. A careful assessment ensures that your final product meets your quality standards and expectations.This evaluation phase is where theory meets practice.

You’ll be looking for specific indicators of print quality, comparing what you see against common printing problems, and verifying that your colors are as vibrant and accurate as they should be. This meticulous review is the cornerstone of a successful print project.

Critical Elements for Inspection

When examining your test print, several key areas demand your attention to ensure the highest quality output. These elements, when assessed diligently, reveal the overall success of the printing process and highlight areas for potential improvement.Here are the crucial aspects to inspect:

- Line Sharpness: Examine fine lines, text edges, and intricate details. They should be crisp and well-defined, without any fuzziness, bleeding, or broken strokes.

- Color Uniformity: Check for consistent color density across solid areas. There should be no banding, mottling, or noticeable variations in hue or saturation within a single color block.

- Registration Accuracy: For multi-color prints, verify that all color layers are perfectly aligned. Misregistration leads to blurry edges where colors meet or unwanted color fringes.

- Ink Coverage: Ensure that ink coverage is adequate and even. Areas that should be solid black should appear truly black, and other colors should be fully opaque where intended.

- Detail Retention: Small text, subtle gradients, and fine patterns should be reproduced faithfully without loss of clarity or definition.

- Surface Finish: Assess the texture and feel of the print. It should be smooth and consistent with the paper or substrate’s intended finish, free from unwanted bumps or imperfections.

Common Printing Imperfections and Their Causes

Understanding common printing defects is vital for diagnosing issues and implementing effective solutions. Each imperfection often points to a specific problem in the printing process, from ink viscosity to mechanical alignment.The following table Artikels common printing imperfections, their visual characteristics, and their most probable causes:

| Imperfection | Visual Description | Potential Causes |

|---|---|---|

| Bleeding | Ink spreading outwards from the intended edges of lines or text, creating a fuzzy or blurred appearance. | Ink viscosity too low, paper absorbency too high, improper ink-to-water balance (in offset printing). |

| Ghosting | A faint, repeated image of a design element appearing elsewhere on the print, often in a lighter shade. | Ink not drying properly, incorrect pressure settings, excessive ink transfer, improper ink viscosity. |

| Banding | Visible horizontal or vertical lines or streaks of lighter or darker color within a solid area. | Issues with ink delivery system, clogged print heads (inkjet), improper roller pressure, uneven ink distribution. |

| Dot Gain | Halftone dots appearing larger than intended, leading to darker overall tones and loss of fine detail. | Excessive ink pressure, paper surface too absorbent, incorrect screen ruling, improper plate processing. |

| Misregistration | Color layers not aligning perfectly, resulting in color fringes or blurry edges where different colors meet. | Mechanical issues with the printing press, incorrect plate or cylinder alignment, loose registration controls. |

| Scumming | Unwanted ink adhering to non-image areas of the printing plate or substrate. | Improper ink-water balance, dirty plates, incorrect pH of fountain solution. |

Assessing Color Accuracy and Saturation

Color is often the most impactful element of a print, and ensuring it is accurate and saturated requires careful comparison against your original digital file or a calibrated reference. Deviations can significantly alter the intended mood and message of your design.To assess color accuracy and saturation effectively, consider these methods:

- Use a Calibrated Monitor: Ensure the monitor you use to view your digital design is properly calibrated. This provides a reliable baseline for color comparison.

- Employ a Color Checker: If possible, print a standard color checker chart alongside your test print. This chart contains known color values that can be used to calibrate your printer and software.

- Visual Comparison: Directly compare the colors on your test print with your digital file on the calibrated monitor. Look for differences in hue, saturation, and brightness.

- Print Swatches: For critical color areas, print isolated swatches of those colors. This allows for a more focused evaluation of individual color reproduction.

- Consider Lighting Conditions: Evaluate your test print under the same lighting conditions where it will ultimately be displayed or used. Different light sources can dramatically alter color perception.

A well-saturated print will exhibit vibrant, rich colors without appearing muddy or dull. Inaccurate colors might lean too warm (reddish), too cool (bluish), or have a washed-out appearance.

Scoring Rubric for Test Print Evaluation

To provide a standardized and objective assessment of your test print quality, a scoring rubric can be highly beneficial. This allows for consistent evaluation across different prints and helps in making informed decisions about proceeding with the full print run.Here is a sample scoring rubric you can adapt for your needs:

| Criteria | Excellent (5 points) | Good (3 points) | Fair (1 point) |

|---|---|---|---|

| Line Sharpness & Detail | All lines and text are exceptionally sharp and crisp with no visible artifacts. Fine details are perfectly retained. | Most lines and text are sharp, with minor, barely noticeable imperfections in very fine details. | Lines and text show noticeable blurriness, jagged edges, or loss of fine detail. |

| Color Accuracy | Colors closely match the digital reference, with negligible deviation in hue and saturation. | Colors are generally accurate, with slight, acceptable variations in hue or saturation. | Colors are noticeably inaccurate, with significant shifts in hue or saturation, or colors appear dull. |

| Color Uniformity & Saturation | Solid color areas are perfectly uniform, smooth, and richly saturated without banding or mottling. | Solid color areas are mostly uniform with very minor, almost imperceptible variations. Saturation is good. | Solid color areas show visible banding, mottling, or unevenness. Saturation is lacking or inconsistent. |

| Registration Accuracy | All color layers are perfectly aligned with no visible fringes or misregistration. | Minor, barely perceptible misregistration in non-critical areas. | Significant misregistration is visible, affecting the clarity and appearance of the design. |

| Ink Coverage & Finish | Ink coverage is solid and even across all areas. The surface finish is smooth and consistent. | Ink coverage is generally good, with very minor inconsistencies. Surface finish is acceptable. | Ink coverage is patchy or uneven. The surface finish has noticeable imperfections. |

Visual Description of a Perfect Test Print

A perfect test print is a testament to a well-executed printing process. It should embody clarity, vibrancy, and precision, reflecting the artist’s or designer’s intent without compromise.Imagine a print where every element is rendered with absolute fidelity:

- Sharp Lines: Text, especially small fonts, should be as sharp as a razor’s edge. Curves should be perfectly smooth, and straight lines should be unwavering. There should be no hint of ink spreading or pixelation.

- Solid Colors: Areas intended to be a solid, deep black should appear as a rich, uniform void. Other solid colors should be dense, opaque, and consistent from one edge of the printed area to the other. There should be no hint of the substrate showing through, nor any visible streaks or variations in tone.

- Accurate Registration: In a multi-color design, the precise alignment of each color layer is paramount. Imagine looking at the edge where a blue shape meets a yellow shape; the transition should be a clean, sharp line. There should be no slivers of white paper showing, nor any color bleeding into the adjacent area. Every hue should sit exactly where it was intended, creating a seamless and professional final image.

In essence, a perfect test print is one where your digital design has been translated into the physical realm with flawless accuracy, leaving no room for doubt about the quality of the final output.

Troubleshooting Common Test Print Problems

Successfully completing a test print is a significant milestone, but it’s not always a perfectly smooth process. Even with meticulous preparation, you might encounter unexpected issues. Understanding these common problems and knowing how to address them is crucial for refining your printing process and achieving consistently high-quality results. This section will guide you through identifying and resolving typical test print failures.

Addressing Print Defects

Print defects can manifest in various ways, impacting the visual appeal and structural integrity of your test print. Recognizing the specific defect is the first step toward a solution.

Smudging

Smudging, often seen as smeared ink or toner, can occur due to several factors. In inkjet printing, it might be caused by the ink not drying properly before handling or by using the wrong type of paper that doesn’t absorb ink effectively. For toner-based prints, smudging can indicate issues with the fuser unit not applying enough heat or pressure, or toner particles not adhering correctly to the paper.

- Inkjet Smudging: Allow adequate drying time, especially with glossy papers. Experiment with different paper types or consider using a quick-drying ink. Ensure the print head nozzles are clean and not clogged, as this can lead to uneven ink application.

- Toner Smudging: Check the fuser unit for any debris or damage. Ensure the paper type is compatible with your printer’s specifications, as some papers require specific fuser temperatures. Clean the toner cartridge and the printer’s paper path according to the manufacturer’s instructions.

Banding

Banding appears as faint lines or stripes across the printed image, indicating an uneven distribution of ink or toner. This can be caused by clogged print heads in inkjet printers, or by worn-out rollers or uneven toner distribution in laser printers.

- Inkjet Banding: Perform a print head cleaning cycle. If the issue persists, a nozzle check pattern can help identify specific clogged nozzles that may require a more intensive cleaning procedure or even replacement of the print head.

- Toner Banding: Run a printer calibration cycle. Inspect the toner cartridge for any signs of clumping or unevenness; shaking the cartridge gently might redistribute the toner. In some cases, worn rollers or drum units may need professional servicing.

Misalignment

Misalignment refers to printed elements not being positioned correctly on the page, or colors not lining up accurately. This can be a result of incorrect paper loading, printer driver settings, or calibration issues.

- Paper Alignment: Ensure paper is loaded correctly in the tray, with guides snug against the paper stack. Check that the paper size and type settings in the print driver match the paper loaded.

- Color Misalignment: Run a printer calibration utility, which is usually found within the printer’s software or control panel. This process realigns the color heads or laser units to ensure accurate color placement.

Managing Extrusion Issues in 3D Printing

In 3D printing, extrusion refers to the process of feeding filament through the hot end and onto the build plate. Incorrect extrusion can lead to significant problems with the printed object’s strength and appearance.

Under-extrusion

Under-extrusion occurs when not enough filament is being deposited, resulting in gaps between lines, weak layer adhesion, and a generally poor surface finish. This can be caused by a clogged nozzle, incorrect filament diameter settings, or a faulty extruder gear.

- Nozzle Clogs: Heat the nozzle to printing temperature and attempt to manually push filament through. If it doesn’t flow freely, a cold pull or using a fine needle to clear the obstruction might be necessary.

- Filament Diameter Settings: Verify the filament diameter setting in your slicer software matches the actual diameter of your filament (e.g., 1.75mm or 2.85mm). Even a small discrepancy can lead to under-extrusion.

- Extruder Calibration: Calibrate your extruder’s E-steps to ensure it is pushing the correct amount of filament. This involves marking a specific length of filament, commanding the extruder to feed that length, and measuring how much was actually fed. Adjust the E-steps value in your printer’s firmware accordingly.

Over-extrusion

Over-extrusion happens when too much filament is deposited, leading to excess material that can cause blobs, zits, and dimensional inaccuracies. This often results in parts that are difficult to assemble or do not fit as intended.

- Flow Rate Adjustment: Reduce the flow rate or extrusion multiplier in your slicer software. A common starting point is to reduce it by 5-10% and observe the results.

- Retraction Settings: Fine-tune retraction settings (distance and speed) in your slicer. Excessive retraction can sometimes lead to pressure buildup and subsequent over-extrusion when printing resumes.

- Nozzle Temperature: Ensure the nozzle temperature is appropriate for the filament being used. If the temperature is too high, the filament can become too viscous, leading to excessive oozing and over-extrusion.

Rectifying Color Inaccuracies and Fading

Color issues in test prints can range from slightly off hues to significant fading, impacting the intended visual representation of your design.

Color Inaccuracies

Inaccurate colors can stem from the printer’s color profiles, the calibration of the monitor used for design, or the ink/toner itself.

- Monitor Calibration: Ensure your monitor is properly calibrated to display colors accurately. Use a calibration tool or follow manufacturer guidelines for color management.

- Printer Profiles: Use the correct ICC profiles for your printer and paper combination. Many printer manufacturers provide specific profiles that optimize color reproduction.

- Ink/Toner Quality: If using third-party inks or toners, they might not be formulated to match the OEM specifications, leading to color shifts. Consider using reputable brands or original manufacturer supplies.

Fading

Fading, particularly in inkjet prints, can be due to lightfastness of the inks or the quality of the paper. For toner prints, it might indicate a problem with the toner density or the fuser.

- Ink Lightfastness: For archival purposes, use inks and papers specifically rated for high lightfastness. Pigment-based inks generally offer better fade resistance than dye-based inks.

- Paper Type: Certain paper coatings can affect ink adhesion and longevity. Acid-free, archival-quality papers are recommended for prints that need to resist fading.

- Toner Density: In laser printers, a low toner density setting or a nearly depleted toner cartridge can lead to faded prints. Check the toner level and adjust density settings if available.

Troubleshooting Flowchart for Common Printing Failures

To systematically address printing issues, a flowchart can be an invaluable tool. This provides a visual guide to diagnosing problems based on observed symptoms.

| Symptom | Potential Cause | Solution |

|---|---|---|

| Smudging | Ink not dry (Inkjet) | Increase drying time, use faster-drying ink, change paper type. |

| Fuser issue (Toner) | Check fuser unit, verify paper compatibility. | |

| Dirty print head (Inkjet) | Perform print head cleaning cycle. | |

| Banding | Clogged print head (Inkjet) | Run nozzle check and cleaning cycles. |

| Uneven toner distribution (Toner) | Shake toner cartridge, run calibration. | |

| Worn rollers (Inkjet/Toner) | Professional service may be required. | |

| Misalignment | Incorrect paper loading | Reload paper, adjust guides, check paper settings. |

| Color calibration needed | Run printer calibration utility. | |

| Under-extrusion (3D) | Nozzle clog | Clean or replace nozzle. |

| Incorrect filament diameter setting | Verify and correct setting in slicer. | |

| Extruder E-steps calibration needed | Calibrate E-steps. | |

| Over-extrusion (3D) | Flow rate too high | Reduce flow rate in slicer. |

| Retraction settings incorrect | Fine-tune retraction distance and speed. | |

| Nozzle temperature too high | Adjust nozzle temperature. | |

| Color Inaccuracy | Monitor not calibrated | Calibrate monitor. |

| Incorrect printer profile | Use appropriate ICC profiles. | |

| Fading | Low lightfastness ink/paper | Use archival-quality materials. |

| Low toner density (Toner) | Check toner level, adjust density settings. |

Material Properties and Their Impact on Print Outcomes

The physical and chemical properties of the materials used in printing, whether it’s ink, toner, or 3D filament, significantly influence the final print quality. Understanding these properties allows for proactive adjustments.

Inkjet Inks

Inkjet inks are typically liquid-based and come in dye or pigment formulations. Dye-based inks offer vibrant colors but are less resistant to fading and water. Pigment-based inks are more durable, water-resistant, and fade-resistant, but can sometimes result in slightly less vibrant colors and may require specific paper types for optimal adhesion.

- Viscosity: Affects how the ink flows through the print head nozzles. If viscosity is too high or too low, it can lead to inconsistent droplet formation, causing banding or poor detail.

- Drying Time: Crucial for preventing smudging. Papers with different absorbency rates will interact differently with ink drying times. Glossy papers often have a longer drying time.

- Lightfastness: The resistance of the ink to fading when exposed to light. Pigment inks generally have superior lightfastness compared to dye inks.

Toner (Laser Printers)

Toner is a dry powder composed of plastic particles, pigment, and other additives. It is fused onto the paper using heat and pressure. The particle size, composition, and melting point of the toner are critical.

- Particle Size and Distribution: Uniform particle size is essential for consistent toner transfer and image quality. Uneven distribution can lead to banding or speckling.

- Melting Point: Dictates the temperature and pressure required by the fuser. If the melting point is too high for the fuser, the toner won’t fuse properly, leading to smudging or poor adhesion. If too low, it can cause excessive gloss or premature fusing.

- Chargeability: Toner particles must acquire and hold an electrostatic charge to be attracted to the photoreceptor drum and then transferred to the paper. Inconsistent chargeability can result in weak images or background noise.

3D Printing Filaments

The vast array of 3D printing filaments, such as PLA, ABS, PETG, and Nylon, each possesses unique characteristics that affect printability and the properties of the final object.

- Glass Transition Temperature (Tg): The temperature at which a material begins to soften. For example, PLA has a lower Tg than ABS, making it more prone to warping at higher ambient temperatures and less suitable for applications requiring high heat resistance.

- Shrinkage and Warping: Materials like ABS are known for significant shrinkage as they cool, which can cause warping, lifting from the build plate, and delamination. Using heated beds and enclosures helps mitigate this. PLA has much lower shrinkage.

- Moisture Absorption: Filaments like Nylon and PETG are hygroscopic, meaning they absorb moisture from the air. Wet filament can lead to popping sounds during printing, poor surface finish, weak parts, and stringing. Proper storage in a dry environment and drying the filament before printing is crucial.

- Adhesion: Different filaments adhere differently to build plate surfaces and to themselves. PLA generally adheres well to glass with adhesives, while PETG might require specific surfaces or release agents to prevent over-adhesion.

- Flexibility and Brittleness: Materials like TPU (Thermoplastic Polyurethane) are flexible, requiring slower print speeds and specific extruder setups. Others, like some PLA blends, can be brittle and prone to snapping if not handled carefully.

Optimizing Settings for Future Prints

The journey of completing your first test print successfully is a significant milestone. However, the true value of this endeavor lies in leveraging the insights gained to refine your printing process for all subsequent projects. This section will guide you through transforming your test print results into actionable strategies for achieving consistently higher quality prints.By meticulously analyzing the outcome of your initial test print, you can identify specific areas for improvement and make informed adjustments to your printer’s settings.

This iterative process of testing, evaluating, and optimizing is fundamental to mastering your 3D printing or general printing workflow.

Refining Future Settings Based on Test Print Results

The data gathered from your first test print is a goldmine of information. It provides direct feedback on how your chosen materials, design, and printer settings interact. Understanding these interactions allows for targeted adjustments that can dramatically improve print quality, reduce failures, and save on material costs.Consider the test print as a diagnostic tool. If you observed stringing, for instance, it points to specific temperature or retraction settings that need attention.

Gaps in layers might indicate issues with extrusion or temperature. Surface imperfections could be related to print speed or cooling. Each flaw or success in the test print offers a clue to unlocking better print outcomes.

Adjusting Print Speed and Temperature for Enhanced Quality

Print speed and temperature are two of the most critical variables that directly impact the aesthetic and structural integrity of your prints. Finding the optimal balance between these settings is key to achieving both speed and quality.* Print Speed: Printing too fast can lead to under-extrusion, layer shifting, and reduced detail. Printing too slow can increase print time unnecessarily and may even cause heat creep issues in FDM printers.

The ideal speed is a compromise that allows for adequate material deposition and cooling without compromising structural integrity or surface finish.

Temperature

The printing temperature, particularly for filament in FDM printing, dictates how well the material flows and adheres to itself and the print bed.To effectively adjust these:

- Start with Material Recommendations: Always begin with the manufacturer’s recommended temperature range for your specific filament or ink.

- Iterative Adjustments: Make small, incremental changes to the temperature and speed. For FDM, a common approach is to print temperature towers, which are models designed to print sections at different temperatures, allowing for direct visual comparison. Similarly, speed can be adjusted in small percentages (e.g., 5-10%).

- Observe and Document: After each adjustment, perform a small test print or a section of your model to observe the impact. Document the changes made and the resulting quality.

Fine-Tuning Layer Height and Infill Density for 3D Prints

For 3D printing specifically, layer height and infill density are paramount for defining the physical properties and visual appearance of your object. These settings have a direct impact on strength, print time, and material consumption.* Layer Height: This setting determines the thickness of each individual layer deposited by the printer. A smaller layer height results in finer detail and smoother surfaces, but significantly increases print time.

A larger layer height prints faster but may result in visible layer lines and less intricate details.

Infill Density

This refers to the percentage of the internal volume of the print that is filled with a support structure. Higher infill density leads to stronger, heavier prints, while lower density results in lighter, faster prints that use less material.To optimize these parameters:

- Layer Height Selection: For highly detailed models or prototypes where surface finish is critical, a layer height of 0.1mm to 0.15mm is often suitable. For functional parts or larger objects where speed is a priority, layer heights of 0.2mm to 0.3mm might be more appropriate.

- Infill Pattern Choice: Different infill patterns (e.g., grid, gyroid, cubic) offer varying strengths and material efficiencies. Experimenting with different patterns can be beneficial for specific applications.

- Infill Density for Strength: For parts requiring high structural integrity, an infill density of 20-50% is common. For display models or objects that do not bear significant load, 10-20% might suffice.

- Balancing Act: The optimal settings for layer height and infill density are often a balance between desired quality, required strength, and acceptable print time.

Designing a System for Documenting Successful Print Settings

Establishing a robust system for documenting your successful print settings is crucial for reproducibility and efficiency. This system will serve as your personal knowledge base, allowing you to quickly recall and apply settings that have yielded excellent results in the past.A well-organized documentation system prevents you from having to reinvent the wheel for every print. It fosters consistency and helps in troubleshooting by providing a baseline of known good settings.Consider the following components for your documentation system:

| Project Name/Description | Material Used | Printer Model | Layer Height (mm) | Print Speed (mm/s) | Printing Temperature (°C) | Bed Temperature (°C) | Infill Density (%) | Infill Pattern | Retraction Settings | Support Settings | Cooling Fan Speed (%) | Notes/Observations | Resulting Quality Rating (e.g., 1-5) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Example: Functional Bracket | PLA – Brand X | Printer Model Y | 0.2 | 50 | 210 | 60 | 20 | Grid | 5mm, 45mm/s | Tree Supports, Everywhere | 100% | Slight stringing observed in previous attempts, adjusted retraction. Good adhesion. | 4 |

| Example: Display Figurine | ABS – Brand Z | Printer Model Y | 0.12 | 40 | 240 | 100 | 15 | Cubic | 6mm, 50mm/s | None | 80% | Excellent surface finish, minimal layer lines. Warping occurred, managed with enclosure. | 5 |

You can implement this system using various tools:

- Spreadsheets: A digital spreadsheet (like Microsoft Excel, Google Sheets, or LibreOffice Calc) is an excellent and versatile option for creating a structured table.

- Dedicated Slicer Profiles: Many 3D printing slicer software programs allow you to save custom print settings as profiles. Naming these profiles descriptively (e.g., “PLA – High Detail,” “PETG – Functional”) can serve as a form of documentation.

- Digital Notebooks/Wikis: Tools like Notion, Ever-note, or a personal wiki can be used to create more narrative-driven documentation, including images of successful prints and detailed troubleshooting notes.

- Physical Logbook: For those who prefer a tangible approach, a well-organized physical logbook can be an effective method.

The key is to choose a method that you will consistently use and that allows for easy retrieval of information when needed.

Understanding Material Considerations for Test Prints

Selecting the right material is a cornerstone of successful test printing. The characteristics of your chosen filament or ink will profoundly influence print quality, dimensional accuracy, and the overall integrity of your initial output. Understanding these nuances allows for more targeted testing and ultimately leads to better results.The journey of a test print begins long before the machine starts humming; it starts with the material itself.

Different materials possess unique properties that dictate how they interact with your printer’s mechanics, temperature settings, and cooling systems. For instance, a material that flows easily at a lower temperature might warp significantly at higher temperatures, leading to a failed test print. Conversely, a material requiring high temperatures might not adhere well if the bed is not sufficiently heated. Therefore, a thoughtful approach to material selection is paramount for a smooth and informative first test print experience.

Impact of Different Material Types on Print Success

The variety of printing materials available, particularly in the realms of 3D printing filaments and inkjet inks, presents a spectrum of behaviors that directly affect test print outcomes. Each material has a unique set of properties including melting point, viscosity, adhesion, shrinkage, and curing characteristics, all of which must be considered. For example, flexible filaments like TPU can be challenging to print without proper extruder calibration and retraction settings due to their tendency to curl or jam.

Similarly, certain high-temperature engineering plastics, such as PEEK or ULTEM, require specialized printers capable of achieving and maintaining extremely high nozzle and bed temperatures, as well as an enclosed build chamber to prevent warping. In the inkjet world, the type of ink – pigment-based versus dye-based – dramatically impacts color vibrancy, lightfastness, and the substrate it can be applied to.

Pigment inks generally offer superior durability and fade resistance but can sometimes lead to less saturated colors compared to dye inks, which can produce more vivid prints but are more prone to fading over time.

Selecting the Appropriate Material for Your Initial Test

The selection of material for your first test print should be guided by your intended application and the capabilities of your printing device. For new 3D printer users, starting with a common and forgiving material like PLA (Polylactic Acid) is highly recommended. PLA is known for its ease of printing, low shrinkage, and good adhesion, making it ideal for learning the fundamentals of your printer.

For those venturing into large-format printing or seeking specific aesthetic qualities, understanding the trade-offs between different paper types or canvas materials is crucial. For example, a glossy photo paper will showcase vibrant colors and sharp details for photographic prints, while a matte fine art paper might be better suited for artistic reproductions where subtle textures and a non-reflective surface are desired.

Best Practices for Storing and Handling Printing Materials

Proper storage and handling of printing materials are essential to prevent degradation and ensure consistent print quality. Many 3D printing filaments, particularly hygroscopic ones like Nylon, PETG, and TPU, absorb moisture from the air. This absorbed moisture can lead to print defects such as stringing, popping sounds during extrusion, and a rough surface finish. To combat this, filaments should be stored in airtight containers or specialized filament dry boxes, ideally with desiccant packs.

Similarly, inkjet inks, especially those containing pigments, can be sensitive to extreme temperatures and prolonged exposure to light, which can cause them to degrade or separate. Keeping ink cartridges or bottles in their original packaging until use, and storing them in a cool, dry place away from direct sunlight, will help maintain their integrity.

Comparing Printing Characteristics of Common Filament Types

The diversity of 3D printing filaments offers a wide range of mechanical and aesthetic properties, each presenting unique challenges and benefits for test prints. Understanding these differences is key to choosing the right material for your needs.

| Filament Type | Key Characteristics | Ideal For | Test Print Considerations |

|---|---|---|---|

| PLA (Polylactic Acid) | Easy to print, low warp, good detail, biodegradable (under specific conditions), wide color range. | Prototypes, general-purpose prints, educational models, decorative items. | Low print temperatures (180-220°C), good bed adhesion with minimal heating (50-60°C), often doesn’t require an enclosure. Excellent for first test prints due to its forgiving nature. |

| PETG (Polyethylene Terephthalate Glycol) | Durable, good layer adhesion, impact resistant, chemical resistant, slightly more flexible than PLA. | Functional parts, mechanical components, food-safe containers (check manufacturer certification). | Higher print temperatures (220-250°C), heated bed (70-80°C), can be prone to stringing, benefits from an enclosure for larger prints. Requires careful retraction tuning. |

| ABS (Acrylonitrile Butadiene Styrene) | Strong, impact resistant, high temperature resistance, can be post-processed (sanded, painted). | Durable parts, automotive components, enclosures, functional prototypes requiring heat resistance. | High print temperatures (230-260°C), high bed temperatures (90-110°C), requires an enclosed printer to manage warping and fumes. Significant shrinkage can be a challenge for test prints. |

| TPU (Thermoplastic Polyurethane) | Flexible, rubber-like, abrasion resistant, impact absorbent. | Phone cases, flexible joints, shock absorbers, wearable items. | Slower print speeds, specific extruder setup (direct drive often preferred), careful retraction settings to avoid jams and stringing. Requires lower print temperatures (210-230°C) and a heated bed (40-60°C). |

| Nylon | Very strong, durable, excellent layer adhesion, good chemical resistance, flexible under load. | Gears, tools, high-wear parts, strong functional components. | Highly hygroscopic (requires drying), high print temperatures (240-270°C), heated bed (70-100°C), often requires an enclosure and specific bed adhesion aids (glue stick, PVA). |

Comparing Printing Characteristics of Common Ink Types

For inkjet printing, the distinction between dye-based and pigment-based inks is fundamental to understanding print longevity, color reproduction, and material compatibility.

- Dye-Based Inks: These inks consist of colorants that are fully dissolved in a liquid carrier. They tend to produce very vibrant and saturated colors, often with a glossy finish. Dye inks typically have a lower cost of production. However, they are generally less resistant to fading from UV light exposure and can bleed on porous surfaces. They are best suited for prints that will be displayed indoors and away from direct sunlight, or for applications where maximum color punch is prioritized over archival quality.

- Pigment-Based Inks: In pigment inks, the colorants are finely ground solid particles suspended in a liquid medium. This suspension makes them inherently more durable and resistant to fading from UV light and moisture. Pigment inks also offer better longevity on a wider range of media, including textured and porous papers. While they may not always achieve the same level of vibrancy as dye inks, they provide superior archival qualities and are the preferred choice for professional photography, fine art prints, and applications requiring long-term display stability.

Last Point

Successfully completing your first test print is more than just a preliminary step; it’s a foundational practice that empowers you with knowledge and control over your printing outcomes. By diligently following the Artikeld procedures for preparation, execution, evaluation, and troubleshooting, you not only mitigate potential risks and save valuable resources but also gain the confidence to refine your processes. Embrace these insights to ensure every subsequent print is closer to perfection, fostering efficiency and unlocking the full potential of your creative projects.