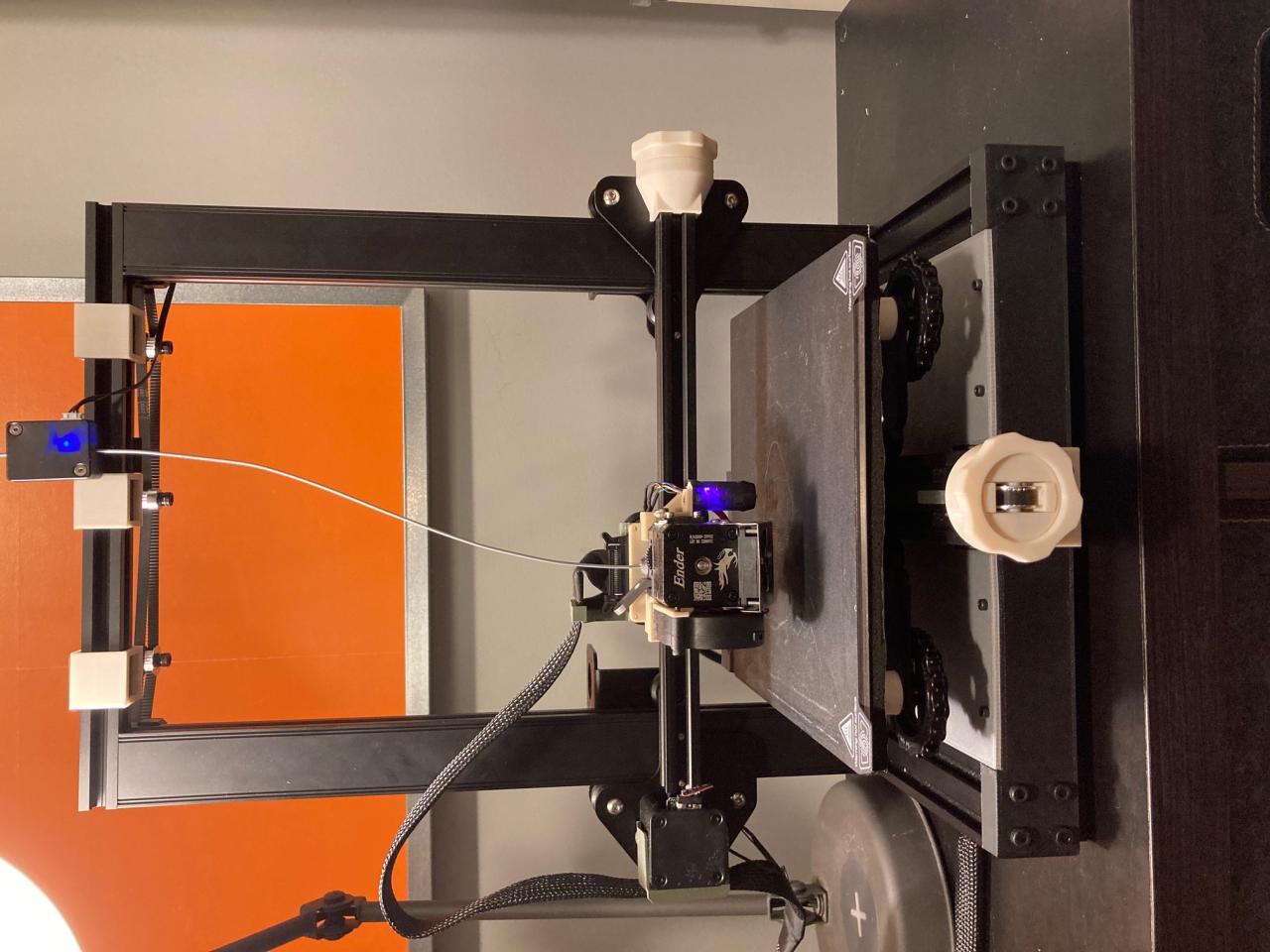

With How to Set Up a Silent Mainboard for Your Printer at the forefront, this paragraph opens a window to an amazing start and intrigue, inviting readers to embark on a journey into quieter and more efficient 3D printing. Discover the transformative power of a silent mainboard and unlock a new level of printing satisfaction.

This comprehensive guide will walk you through the entire process, from understanding the core benefits and components of silent mainboards to the detailed steps of installation, firmware configuration, and post-upgrade calibration. We aim to equip you with the knowledge and confidence to successfully implement this upgrade and enjoy a significantly enhanced printing experience.

Understanding Silent Mainboards for Printers

In the realm of 3D printing, the operation of a printer can sometimes be accompanied by a considerable amount of noise. This noise primarily originates from the stepper motors that control the precise movements of the print head and build plate. A silent mainboard is specifically designed to mitigate this acoustic disturbance, transforming a potentially noisy printing experience into a much quieter and more pleasant one.

Its fundamental purpose is to enhance the user experience by reducing the operational sound levels of the 3D printer.The integration of a silent mainboard represents a significant upgrade for any 3D printer owner seeking a more tranquil environment. These specialized boards employ advanced technology to significantly dampen the vibrations and electrical noise generated by stepper motor drivers. This leads to a noticeable reduction in the characteristic grinding and whining sounds typically associated with 3D printing, allowing for printing in shared living spaces or during quiet hours without disruption.

Key Components Differentiating Silent Mainboards

The core difference between a silent mainboard and a standard one lies in the type of stepper motor drivers integrated onto the board. Standard mainboards often utilize older, less sophisticated drivers that are prone to producing audible noise. Silent mainboards, on the other hand, incorporate advanced drivers that operate with smoother, more controlled current modulation.The primary components responsible for this silent operation are the stepper motor drivers themselves.

These drivers manage the flow of electricity to the stepper motors, dictating their speed and direction. Silent mainboard drivers utilize technologies such as SpreadCycle and StealthChop, which are proprietary advancements from manufacturers like Trinamic.

- SpreadCycle: This technology offers a dynamic control of the stepper motor current. It intelligently switches between different microstepping modes to optimize torque and minimize resonance, which is a major source of audible noise.

- StealthChop: This is a highly advanced driver mode that focuses on extremely quiet operation, especially at lower speeds. It achieves this by precisely controlling the current to the motor coils, resulting in smooth, near-silent movements.

- Advanced Filtering and Power Regulation: Beyond the drivers, silent mainboards often feature improved electronic components for filtering electrical noise and more stable power regulation. This contributes to the overall reduction of electromagnetic interference that can manifest as audible hums or buzzes.

Advantages of Upgrading to a Silent Mainboard

Upgrading a 3D printer with a silent mainboard offers a multitude of benefits that extend beyond mere noise reduction. These advantages contribute to a more refined and user-friendly printing experience, making the printer more accessible and less intrusive in various environments.The primary advantages revolve around improved user comfort, enhanced precision, and greater flexibility in printer placement and usage.

- Reduced Noise Pollution: This is the most immediate and noticeable benefit. The significant reduction in operational noise makes the printer far less distracting, allowing for work, study, or sleep in proximity to the printer without disturbance.

- Enhanced Print Quality: The smoother operation of stepper motors, facilitated by advanced drivers, can lead to more precise movements. This often translates into finer details, reduced ringing artifacts, and overall improved surface finish on printed objects.

- Increased Printer Placement Flexibility: A quieter printer can be placed in a wider range of locations. It can be moved from a dedicated workshop to a living room, office, or even a bedroom without causing significant acoustic inconvenience.

- Improved User Experience: The overall experience of owning and operating a 3D printer becomes more enjoyable when the machine is less obtrusive. This can encourage more frequent use and experimentation.

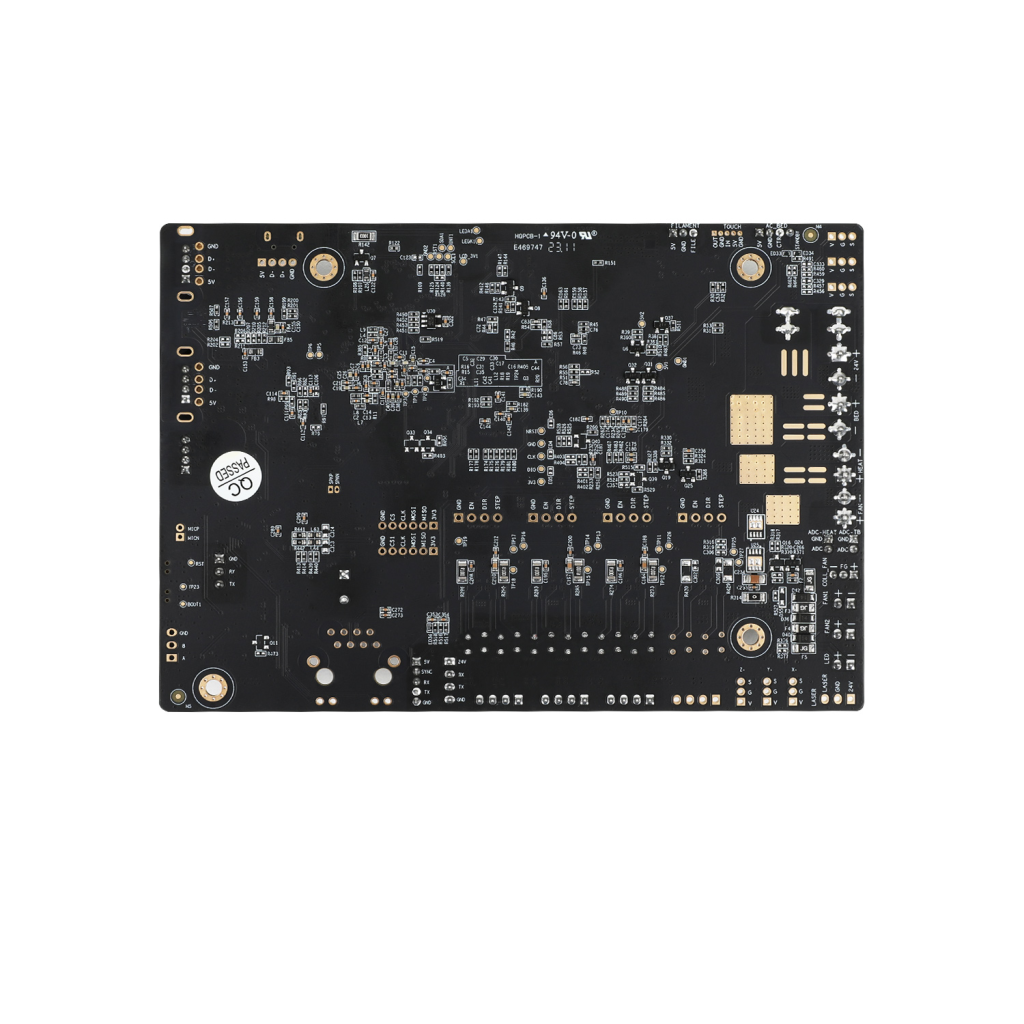

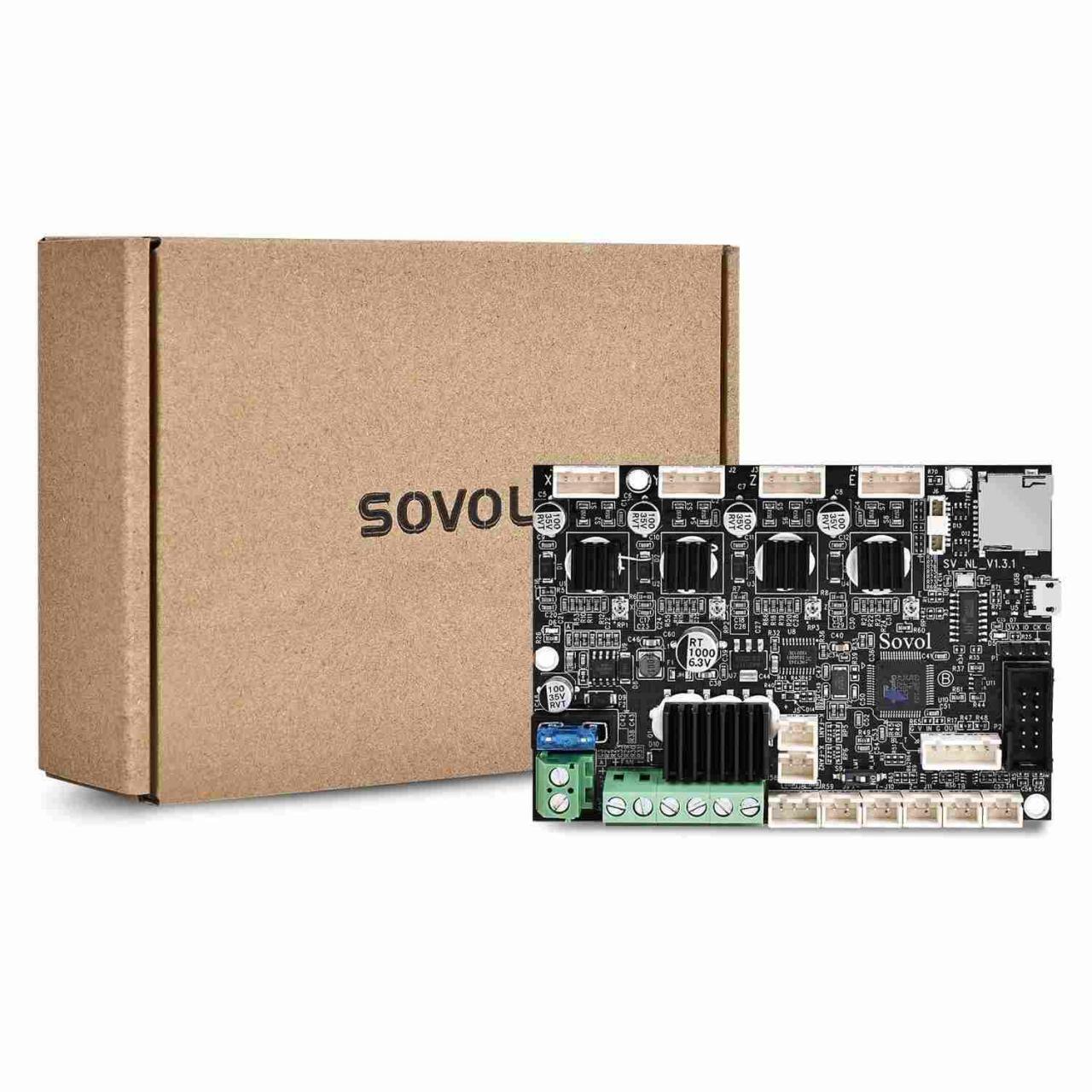

Common Types of Silent Mainboards

The market offers a variety of silent mainboards, catering to different printer models and user preferences. These boards often differ in their microcontroller, the number and type of stepper motor drivers, and additional features. Understanding these variations can help in selecting the most suitable upgrade.Many popular 3D printer manufacturers are now integrating silent mainboards as standard in their newer models.

For those looking to upgrade older printers, a wide range of aftermarket options are available.

| Mainboard Type | Key Features | Compatibility Notes |

|---|---|---|

| Dedicated Silent Boards | Often feature 4 or 5 integrated TMC2208, TMC2209, or similar silent stepper drivers. Typically use 32-bit microcontrollers for faster processing. | Designed for specific printer models or as universal upgrades. Require firmware configuration. |

| Mainboards with Upgradeable Driver Sockets | Allow users to install their choice of silent stepper drivers (e.g., TMC2208, TMC2209, TMC2130) into dedicated sockets. | Offers flexibility but requires purchasing drivers separately. Firmware configuration is essential. |

| All-in-One Boards with Integrated Silent Drivers | Combine the microcontroller, power regulation, and multiple silent stepper drivers on a single board. | Often designed for ease of installation and firmware simplicity. Common in DIY kits and some commercial printers. |

| Boards with Separate Silent Driver Modules | Some boards are designed to work with external silent driver modules that connect via ribbon cables. | Provides a modular approach to upgrading and can offer advanced features. |

When selecting a silent mainboard, it is crucial to verify compatibility with your specific 3D printer model, including its firmware requirements and physical dimensions. Popular choices often include boards from manufacturers like SKR (BigTreeTech), Creality (for their Ender series), and MKS.

Prerequisites and Preparation for Installation

Before embarking on the exciting journey of upgrading your printer’s mainboard to a silent model, it’s crucial to ensure you have all the necessary tools and have completed essential preparatory steps. This phase is designed to make the installation process as seamless and stress-free as possible, minimizing the risk of errors and ensuring the longevity of your printer. Proper preparation is key to a successful upgrade.Taking the time to gather the right equipment and follow a structured checklist will not only make the physical installation easier but also safeguard your printer’s existing configurations.

This section will guide you through identifying the tools you’ll need, outlining pre-installation checks, detailing how to safely handle the power and old mainboard removal, and explaining the vital process of backing up your printer’s firmware settings.

Essential Tools and Materials

Having the correct tools readily available is fundamental for a smooth and efficient silent mainboard installation. These items are designed to handle delicate electronic components and ensure proper connectivity.A comprehensive list of required tools and materials includes:

- Screwdriver Set: A set of small Phillips head screwdrivers is essential for removing screws from the printer’s casing and the old mainboard. Magnetic tips can be particularly helpful for preventing dropped screws.

- Anti-static Wrist Strap: This is a critical safety item to prevent electrostatic discharge (ESD), which can damage sensitive electronic components like the mainboard.

- Pliers: Small needle-nose pliers can be useful for gripping and disconnecting small wires and connectors.

- Wire Strippers/Cutters: While not always necessary, these can be helpful if any wiring modifications are required.

- Zip Ties or Cable Management Sleeves: For organizing wires neatly after the new mainboard is installed, improving airflow and preventing snags.

- Small Container or Tray: To keep screws and small parts organized and prevent them from getting lost.

- Digital Multimeter (Optional but Recommended): For verifying power connections and continuity if troubleshooting is needed.

- New Silent Mainboard: Ensure you have purchased a mainboard that is compatible with your specific printer model.

- Printer Manual: Referencing your printer’s original manual can provide specific details about its internal layout and screw locations.

Pre-Installation Checklist

Completing a thorough pre-installation checklist will significantly reduce the chances of encountering unexpected issues during the upgrade process. This proactive approach ensures all bases are covered before you begin disassembling your printer.Before you start, please ensure the following steps have been completed:

- Research Compatibility: Confirm that the silent mainboard you have purchased is fully compatible with your printer model. Check manufacturer specifications and community forums for confirmation.

- Gather Tools: Ensure all the essential tools listed above are readily accessible and in good working condition.

- Clear Workspace: Designate a clean, well-lit, and static-free workspace for the installation. Avoid working on carpeted surfaces if possible.

- Read New Mainboard Documentation: Familiarize yourself with the installation guide and any specific instructions provided with your new silent mainboard.

- Power Off and Unplug: Absolutely ensure the printer is powered off and its power cord is disconnected from the wall outlet.

- Discharge Residual Power: After unplugging, press and hold the printer’s power button for about 15-30 seconds to discharge any residual power within the system.

- Ground Yourself: Wear an anti-static wrist strap and connect it to a grounded metal object to prevent static electricity from damaging components.

- Take Photos: Before disconnecting any wires or removing components, take clear, detailed photos of the existing mainboard and its connections. This will serve as a visual reference during reassembly.

Safely Disconnecting Power and Removing the Old Mainboard

The process of disconnecting power and removing the old mainboard requires careful attention to detail to prevent damage to your printer. Following these steps ensures a safe and methodical removal.The initial steps involve safely isolating the printer from any electrical source and then proceeding with the physical disassembly.

- Confirm Power Disconnection: Double-check that the printer is switched off and the power cable is completely unplugged from the wall socket.

- Locate Printer Casing Screws: Refer to your printer’s manual or your pre-installation photos to identify all screws securing the printer’s outer casing. These are typically located on the back, sides, and sometimes underneath the printer.

- Remove Casing: Carefully remove the screws and gently separate the printer’s casing panels. Some panels may slide or clip into place, so avoid forcing them.

- Identify the Mainboard: Once the casing is open, locate the main electronic control board. It’s usually a large circuit board with numerous connectors and wires attached.

- Document Wire Connections: Before disconnecting any wires, use your pre-taken photos or label each wire with its corresponding connector. Note the orientation and color coding of each wire.

- Disconnect Wires: Gently disconnect each wire from the old mainboard. Most connectors have small clips or latches that need to be pressed or lifted. Avoid pulling on the wires themselves; grip the connector housing.

- Remove Mainboard Screws: Identify and remove the screws that secure the old mainboard to the printer’s chassis.

- Lift Out the Old Mainboard: Carefully lift the old mainboard straight up and out of its mounting points. Be mindful of any remaining cables or components it might be connected to.

Backing Up Printer Firmware Settings

Before installing a new mainboard, it is highly recommended to back up your current printer’s firmware settings. This backup can be invaluable if you need to restore specific configurations or parameters that are not automatically transferred to the new board, or if you encounter any issues and need to revert to the original setup.The process for backing up firmware settings can vary depending on your printer model and the firmware it uses.

However, a general approach often involves using specific software or accessing the printer’s internal menu.For printers utilizing Marlin firmware or similar open-source firmware, the process typically involves:

- Connect to the Printer: Establish a connection between your computer and the printer. This is commonly done via a USB cable.

- Open a Terminal Interface: Use a serial terminal program such as Pronterface, OctoPrint’s terminal tab, or even a simple terminal emulator (like PuTTY on Windows or the built-in Terminal on macOS/Linux).

- Identify the Correct COM Port: Ensure you have selected the correct COM port associated with your printer in the terminal software.

- Send Firmware Commands: You will need to send specific G-code commands to retrieve the current settings. A common command to save configuration to EEPROM is `M500`, which saves current settings. To retrieve settings, you might need to send `M501` (read settings from EEPROM) or `M503` (report current settings).

- Capture the Output: Once the command is sent, the printer’s settings will be displayed in the terminal window. Copy and paste this entire output into a plain text file.

- Save the Configuration File: Save this text file in a safe and easily accessible location on your computer. Label it clearly with the date and printer model for future reference.

For printers with proprietary firmware, the backup process might be integrated into the printer’s onboard menu or require specific manufacturer software. Always refer to your printer’s user manual or the manufacturer’s support website for the most accurate instructions. A typical example of what you might find in a menu would be an option like “Backup Settings” or “Save Configuration to SD Card.”

Physical Installation of the Silent Mainboard

This section guides you through the hands-on process of integrating your new silent mainboard into your printer. A careful and methodical approach is crucial to ensure all connections are secure and correctly placed, preventing potential damage to your components and ensuring optimal performance of your upgraded printer.The physical installation involves carefully removing the old mainboard, mounting the new one, and meticulously reconnecting all essential peripherals.

Attention to detail during this phase is paramount for a successful silent upgrade.

Mounting the Silent Mainboard

The new silent mainboard needs to be securely fastened within the printer’s chassis. Most printers have specific mounting points designed to accommodate the mainboard.

Before proceeding, ensure the printer is completely powered off and unplugged from the wall outlet. It is also advisable to wear an anti-static wrist strap to prevent electrostatic discharge, which can damage sensitive electronic components.

- Locate the existing mainboard within your printer’s electronics enclosure.

- Carefully disconnect all cables attached to the old mainboard. It’s highly recommended to take pictures or make notes of each connection before disconnecting them.

- Unscrew and remove the old mainboard from its mounting points.

- Align the new silent mainboard with the mounting holes in the chassis.

- Secure the new mainboard using the appropriate screws. Do not overtighten.

Connecting Stepper Motor Drivers and Endstop Sensors

Stepper motor drivers are responsible for the precise movement of your printer’s axes, while endstop sensors detect the limits of these movements. Correctly connecting these components to the new silent mainboard is vital for accurate printing.

Silent mainboards often utilize pluggable stepper motor drivers, making this process simpler and less prone to wiring errors compared to boards with integrated drivers. Similarly, endstop connections are typically straightforward.

- Stepper Motor Drivers: Ensure each stepper motor driver is inserted into its designated socket on the mainboard. Pay close attention to the orientation of the driver, as it usually has a specific key or notch to prevent incorrect insertion. The pins on the driver must align perfectly with the socket. Refer to the silent mainboard’s documentation for the correct placement of drivers for X, Y, Z, and Extruder axes.

- Endstop Sensors: Connect the wires from your endstop sensors (usually microswitches or optical sensors) to the corresponding endstop pins on the mainboard. These pins are typically labeled as X-STOP, Y-STOP, Z-STOP, etc. Verify the polarity of the connection as specified in your mainboard’s manual. Some setups may require specific wiring configurations for normally open (NO) or normally closed (NC) switches.

Wiring Power Supply and Fan Connections

Properly wiring the power supply and fan connections ensures your silent mainboard and its components receive stable power and adequate cooling.

The main power input for the board and connections for cooling fans are critical for the operational integrity of your printer. Incorrect wiring here can lead to component failure or overheating.

- Power Supply: Connect the main power input wires from your printer’s power supply unit (PSU) to the designated power terminals on the silent mainboard. These terminals are usually clearly marked as VIN or PWR. Ensure the positive (+) and negative (-) connections are made correctly according to the mainboard’s specifications. Incorrect polarity can cause immediate damage.

- Fan Connections: Connect your printer’s cooling fans (e.g., hotend fan, part cooling fan, motherboard fan) to the fan headers on the silent mainboard. These headers are typically labeled as FAN0, FAN1, etc. Some boards may offer PWM (Pulse Width Modulation) control for fans, allowing for variable speed. Consult your mainboard’s documentation for specific fan header assignments and control capabilities.

Typical Silent Mainboard Connector Pinout Diagram

To aid in the connection process, understanding the typical pinout for common silent mainboard connectors is beneficial. While specific layouts can vary between manufacturers, certain conventions are widely adopted.

The following diagram illustrates a generalized pinout for common connectors found on many silent mainboards. Always refer to your specific mainboard’s documentation for the definitive pinout.

| Connector Label | Purpose | Typical Pins | Notes |

|---|---|---|---|

| STEPPER | Stepper Motor Connections | 1A, 1B, 2A, 2B | Connects to stepper motor coils. Orientation is crucial. |

| ENDSTOP | Endstop Sensor Connections | GND, SIGNAL, +5V (or similar) | Connects to limit switches or sensors. Polarity matters. |

| THERM | Thermistor Connections | TEMP1, TEMP2 (or similar) | Connects to hotend and bed thermistors for temperature sensing. |

| HEATER | Heater Cartridge Connections | BED, HOTEND (or similar) | Connects to the heating elements for the print bed and hotend. |

| FAN | Fan Connections | +12V/24V, GND, PWM (optional) | For cooling fans. Check voltage compatibility. |

| POWER | Main Power Input | VIN+, VIN- (or +12V/24V, GND) | Connects to the printer’s power supply. Polarity is critical. |

| SERVOS | Servo Motor Connections (if applicable) | PWM, GND, +5V | For features like auto-bed leveling probes. |

Firmware Configuration and Updates

Once your silent mainboard is physically installed, the next critical step is to configure its firmware to communicate effectively with your printer and its new silent drivers. This process ensures optimal performance, quiet operation, and the safety of your printer’s components. This section will guide you through flashing new firmware, adjusting essential stepper motor and thermistor settings, and enabling the silent features of your new mainboard.

Firmware Flashing Process

Flashing new firmware is the essential process of transferring the updated or new firmware code from your computer to the mainboard’s microcontroller. This replaces the existing firmware with the new configuration, enabling the silent features and setting up the board for your specific printer. The exact method can vary slightly depending on the mainboard model and the firmware you are using (e.g., Marlin, Klipper, RepRapFirmware), but the general principles remain consistent.The typical firmware flashing process involves the following steps:

- Download Firmware: Obtain the correct firmware version for your silent mainboard and printer model. This is often available from the mainboard manufacturer’s website or a reputable firmware project like Marlin.

- Configure Firmware: Before flashing, you will likely need to configure the firmware to match your printer’s specific hardware. This involves editing configuration files (e.g., `Configuration.h` and `Configuration_adv.h` for Marlin) to set parameters like board type, thermistor types, bed dimensions, and stepper driver types.

- Compile Firmware: Use a compatible compiler (e.g., PlatformIO with VS Code for Marlin) to compile the configured firmware code into a machine-readable file (often a `.hex` or `.bin` file).

- Connect to Mainboard: Connect your computer to the silent mainboard using a USB cable.

- Upload Firmware: Use a flashing tool (e.g., Pronterface, Cura’s built-in uploader, or a bootloader utility) to transfer the compiled firmware file to the mainboard. For some boards, you might need to put the board into bootloader mode by pressing a reset button or shorting specific pins.

- Verify Installation: After flashing, disconnect and reconnect the USB cable, and connect to your printer via a host software to ensure the new firmware is recognized and functioning correctly.

Stepper Motor Configuration

Properly configuring your stepper motor settings is paramount for smooth, precise, and silent movement of your printer’s axes. These settings directly influence how the stepper motor drivers interpret movement commands, affecting torque, speed, and noise levels.Key stepper motor settings to configure include:

- Microstepping: This setting determines how finely the stepper motor’s full steps are divided. Higher microstepping values (e.g., 1/16, 1/32, 1/64, 1/256) result in smoother and quieter motor operation by reducing the noticeable “steps” the motor makes. The silent stepper drivers are specifically designed to excel at higher microstepping levels.

- Current: The current setting controls the amount of electrical current supplied to the stepper motor coils. It needs to be set appropriately to provide sufficient torque for movement without overheating the motor or the driver. Consult your motor and driver datasheets for recommended current values. Incorrect current settings can lead to skipped steps or premature component failure.

- Steps per Millimeter (Steps/mm): This calibration value tells the printer’s firmware how many steps the stepper motor needs to take to move a specific distance (e.g., 1 millimeter) along an axis. It’s typically calculated based on the motor’s step angle, the driver’s microstepping, and the mechanics of your printer (e.g., belt pitch, lead screw pitch). Accurate Steps/mm are crucial for dimensional accuracy in your prints.

You can often adjust these settings directly within the firmware’s configuration files or sometimes through G-code commands, though direct firmware configuration is generally preferred for permanent changes.

Thermistor and Temperature Protection Settings

The silent mainboard’s ability to accurately monitor and control temperatures is vital for successful printing and preventing damage to your printer. Thermistors are temperature-sensitive resistors that provide feedback to the mainboard, and temperature protection parameters ensure safe operating limits are maintained.Important thermistor and temperature protection settings include:

- Thermistor Type: The firmware needs to know the specific type of thermistor used for your hotend and heated bed. This is crucial for the firmware to accurately translate the thermistor’s resistance changes into actual temperature readings. Different thermistors have different resistance curves, and selecting the wrong type will lead to inaccurate temperature control.

- PID Tuning: Proportional-Integral-Derivative (PID) tuning is an algorithm used to regulate the temperature of the hotend and heated bed. Properly tuned PID settings ensure that the target temperature is reached quickly, maintained stably, and minimizes temperature fluctuations (overshoot and undershoot). Most firmware packages include a PID autotune function.

- Maximum Temperatures: Setting maximum allowable temperatures for the hotend and heated bed is a critical safety feature. This prevents accidental overheating that could damage the nozzle, heat block, bed surface, or even cause a fire.

- Thermal Runaway Protection: This essential safety feature monitors the temperature readings from the thermistors. If the temperature deviates significantly from the expected value (e.g., if the heater is on but the temperature isn’t rising, or if the temperature continues to rise uncontrollably after the heater is turned off), the firmware will halt the printer to prevent potential damage or hazards.

These settings are typically configured within the main firmware files and can be fine-tuned through dedicated G-code commands after initial setup.

Silent Stepper Motor Driver Configuration

The primary benefit of a silent mainboard often lies in its integrated silent stepper motor drivers. Enabling and configuring these drivers within the firmware unlocks their full potential for quiet operation.To enable and configure silent stepper motor drivers:

- Driver Selection: In your firmware configuration files, you will need to specify which type of silent stepper drivers your mainboard is using (e.g., TMC2208, TMC2209, TMC5160). This tells the firmware how to communicate with the drivers.

- Driver Mode: Silent stepper drivers often support various operating modes, such as StealthChop, SpreadCycle, or combinations thereof. StealthChop is typically the mode for silent operation, while SpreadCycle offers higher torque at higher speeds. You will configure which mode is active for each axis.

- Advanced Features: Many silent drivers support advanced features like StallGuard (sensorless homing) and CoolStep. StallGuard can detect when a motor encounters resistance and can be used for homing without physical endstops. CoolStep dynamically adjusts motor current based on load, saving power and reducing heat. Enabling and configuring these features requires specific settings within the firmware.

- UART/SPI Communication: Some advanced silent drivers can be configured via UART or SPI communication protocols, allowing for dynamic adjustment of settings like microstepping and current directly from the firmware without physical jumpers. If your board and drivers support this, you will need to enable the relevant communication interface in the firmware.

The specific settings and syntax for configuring these drivers will be detailed in the documentation for your chosen firmware and your silent mainboard. Always refer to these resources for precise instructions.

Testing and Calibration After Installation

Congratulations on successfully installing your silent mainboard! This next crucial phase involves thoroughly testing and calibrating your printer to ensure optimal performance and to fully appreciate the benefits of your upgrade. This section will guide you through a comprehensive testing procedure, calibration routines, and a comparison of noise levels, along with a troubleshooting guide for any potential issues.The transition to a silent mainboard is not just about noise reduction; it’s about enhancing the precision and reliability of your 3D printer.

A well-executed testing and calibration process will ensure that your printer’s movements are not only quiet but also incredibly smooth and accurate, leading to improved print quality and a more pleasant printing experience.

Motor Movement Testing

To confirm that your silent mainboard is functioning as intended, a detailed testing procedure focusing on motor movements is essential. This involves systematically checking each axis for silent operation and smooth, consistent motion.The following steps will help you verify the silent and smooth operation of all motor movements:

- X-Axis Movement Test: Initiate a print or manually command the X-axis to move from one end to the other at various speeds. Listen for any grinding, buzzing, or clicking sounds. Observe the movement for any jerky or uneven travel.

- Y-Axis Movement Test: Repeat the process for the Y-axis, moving the print bed from front to back. Pay close attention to the sound and the smoothness of the bed’s motion.

- Z-Axis Movement Test: Test the Z-axis by commanding it to move up and down through its entire range. For printers with dual Z-axis motors, ensure both motors are synchronized and move in unison without any noticeable lag or difference in sound.

- Extruder Motor Test: Manually command the extruder motor to feed filament forward and backward at different rates. Listen for any unusual noises and observe the consistency of filament movement.

- Silent Stepper Driver Verification: While performing these tests, it is important to note the absence of the characteristic high-pitched whine or buzzing commonly associated with older stepper drivers. The sound should be significantly reduced, often to a faint whirring or almost imperceptible hum.

Extruder and Bed Leveling Calibration

After confirming the silent operation of your motors, it is vital to recalibrate your extruder and bed leveling to ensure print accuracy and adhesion. The silent mainboard itself doesn’t inherently change these parameters, but it’s a perfect opportunity to fine-tune them for optimal results.A systematic calibration routine will enhance your print quality and reliability:

Extruder Calibration (E-Steps)

Extruder calibration, often referred to as E-steps calibration, ensures that your printer extrudes the correct amount of filament for each command. This is critical for achieving accurate layer heights and preventing under or over-extrusion.

- Prepare for Calibration: Heat your nozzle to your typical printing temperature and ensure there is no filament loaded.

- Mark the Filament: Manually feed a small amount of filament and then measure 120mm from the extruder inlet. Mark this point clearly with a marker.

- Command Extrusion: Using your printer’s interface or G-code commands, command the extruder to extrude 100mm of filament.

- Measure Remaining Filament: After the command completes, measure the distance from the extruder inlet to your mark. The remaining length should be 20mm (120mm initial – 100mm extruded).

- Calculate New E-steps: If the remaining length is not 20mm, you will need to calculate your new E-steps value. The formula is:

New E-steps = (Current E-steps

100) / (Actual extruded length)

For example, if your current E-steps are 93, and you actually extruded 95mm instead of 100mm, your new E-steps would be (93 – 100) / 95 = 97.89.

- Update Firmware: Enter the new E-steps value into your printer’s firmware or EEPROM settings.

Bed Leveling Calibration

Accurate bed leveling is fundamental for successful first layers and overall print adhesion. This process ensures that the nozzle maintains a consistent distance from the print bed across its entire surface.

- Manual Bed Leveling: If your printer has manual bed leveling knobs, perform the standard procedure of adjusting each corner until a piece of paper can slide with slight resistance between the nozzle and the bed.

- Automatic Bed Leveling (ABL) Setup: If you have an ABL sensor, initiate the ABL routine through your printer’s menu. Ensure the sensor is clean and properly mounted. After the routine, it’s good practice to perform a manual check at a few points to confirm the sensor’s accuracy.

- Z-Offset Adjustment: Fine-tune your Z-offset to achieve the perfect squish for your first layer. This is done by making small adjustments to the nozzle’s starting height.

Noise Level Comparison

A significant benefit of upgrading to a silent mainboard is the reduction in operational noise. Comparing the noise levels before and after the installation will highlight the effectiveness of your upgrade.To effectively gauge the noise reduction, consider the following:

- Baseline Measurement: Before installing the silent mainboard, run a standard print or a series of motor movements. Use a sound meter app on your smartphone or a dedicated decibel meter placed at a consistent distance (e.g., 1 meter) from the printer. Record the average and peak decibel levels.

- Post-Installation Measurement: After installing the silent mainboard and completing the calibration, repeat the exact same print or motor movement test under identical conditions. Record the new average and peak decibel levels.

- Qualitative Assessment: Beyond numerical readings, subjectively assess the type of noise. Older mainboards often produce high-pitched whining or buzzing. Silent mainboards typically produce a much softer, lower-frequency hum or whir, which is far less intrusive.

You can expect a reduction of anywhere from 10 to 20 decibels, and in some cases, even more, depending on the specific drivers and printer design. This translates to a significantly quieter printing environment, making it more feasible to have your printer operating in living spaces or shared offices.

Troubleshooting Common Post-Installation Issues

While the installation of a silent mainboard is generally straightforward, occasional issues may arise. Having a troubleshooting guide at hand will help you quickly resolve any problems encountered.Here are some common issues and their potential solutions:

| Issue | Potential Cause | Solution |

|---|---|---|

| Motor not moving or moving erratically | Incorrect wiring of stepper motor cables. Loose connections. Incorrect stepper driver configuration in firmware. | Double-check all stepper motor connections against the wiring diagram. Ensure all pins are fully seated. Verify stepper driver settings in your firmware (e.g., TMC2208, TMC2209). |

| Excessive noise despite silent mainboard | Stepper driver current is set too high. Mechanical binding in the axis. Firmware not properly configured for silent mode (e.g., StealthChop vs. SpreadCycle). | Adjust stepper driver current if adjustable. Check for any obstructions or misalignments in the printer’s mechanics. Ensure your firmware is correctly configured to utilize the silent operation modes of the drivers. |

| Print quality issues (e.g., layer shifting, under/over-extrusion) | Incorrect E-steps calibration. Bed leveling issues. Loose belts or pulleys. | Re-perform E-steps calibration. Ensure bed leveling is precise and Z-offset is correctly set. Check belt tension and tighten any loose pulleys. |

| Printer not booting or showing errors | Incorrect power supply connection. Short circuit. Firmware flash failed. | Verify power supply connections are secure and correct polarity. Inspect the mainboard for any visible damage or loose components. Re-flash the firmware, ensuring you are using the correct version for your mainboard. |

| Endstops not triggering or behaving erratically | Loose endstop wiring. Incorrect endstop configuration in firmware. Damaged endstop switch. | Check all endstop connections for looseness. Verify endstop logic (normally open/closed) and pin assignments in your firmware. Test endstop switches individually if possible. |

Enhancing Printer Performance with Silent Operation

Upgrading your printer’s mainboard to a silent model offers more than just a reduction in noise; it can significantly enhance the overall printing experience and even contribute to improved print quality. By minimizing mechanical vibrations and creating a more stable printing environment, you unlock new potentials for your 3D printer. This section explores how to maximize these benefits and further refine your printer’s acoustic and performance characteristics.The transition to a silent mainboard fundamentally alters the sensory feedback of your 3D printer.

Gone are the often-jarring mechanical noises, replaced by a much softer hum. This transformation is not merely about personal comfort; it creates a more focused and less distracting workspace, allowing for longer print sessions without fatigue and fostering a more conducive environment for creative endeavors or critical tasks.

Reduced Vibration and Print Quality

Silent mainboards, particularly those featuring TMC stepper motor drivers, operate by employing advanced microstepping techniques. These techniques divide each full step of a motor into many smaller microsteps, resulting in smoother motor movement. This smoothness directly translates to a reduction in high-frequency vibrations that can travel through the printer’s frame and affect the print bed and nozzle.The impact of reduced vibration on print quality can be substantial.

Unwanted vibrations can cause artifacts such as ringing, ghosting, or layer inconsistencies. By minimizing these mechanical disturbances, the print head can move with greater precision and stability, leading to sharper details, smoother surfaces, and more accurate dimensional fidelity in your printed objects. This is especially noticeable in prints requiring fine details or smooth curves.

Optimizing Printer Acoustics Beyond the Mainboard

While a silent mainboard is a significant step, further acoustic optimization can yield even quieter and more stable printing. Addressing other mechanical components and structural elements can create a truly serene printing experience.Consider the following areas for further acoustic refinement:

- Frame Damping: Adding vibration-damping materials to the printer’s frame, such as sorbothane pads or specialized foam, can absorb residual vibrations before they propagate.

- Enclosure Benefits: A well-designed 3D printer enclosure not only helps maintain stable printing temperatures but also acts as a sound dampener, significantly reducing the noise that escapes into the room.

- Fan Upgrades: Noisy fans are a common source of printer sound. Replacing stock fans with quieter, high-quality alternatives designed for low noise operation can make a noticeable difference.

- Belt Tensioning: Properly tensioned belts contribute to smoother movement. Overly loose or tight belts can introduce unnecessary noise and vibration.

- Surface Resonance: Ensure your printer is placed on a stable, non-resonant surface. A heavy, solid surface will absorb more vibrations than a flimsy one.

Advanced Configuration for Silent Mainboard Capabilities

Silent mainboards offer advanced configuration options that can be leveraged to further enhance performance and tailor the printing experience. These settings often relate to the sophisticated control offered by TMC stepper drivers.Here are some advanced configuration options to explore:

- StealthChop™ vs. SpreadCycle™: TMC drivers typically offer multiple operating modes. StealthChop™ is optimized for silent operation and is ideal for most printing scenarios. SpreadCycle™ offers higher torque and is better suited for rapid movements where noise is less of a concern, though it is inherently louder. Understanding when to use each can be beneficial.

- Microstepping Levels: While silent mainboards often default to high microstepping (e.g., 1/16, 1/32, or even 1/256), experimenting with different levels can sometimes fine-tune performance. Higher microstepping generally means smoother motion but can slightly reduce torque.

- Current Control (RMS/Peak): Advanced firmware might allow for fine-tuning the current supplied to the stepper motors. Adjusting this can balance motor performance, heat generation, and noise. It is crucial to consult your mainboard’s documentation and use caution when modifying these settings to avoid overheating or damaging the motors.

- Stall Detection and Sensorless Homing: Many silent mainboards support sensorless homing, which uses the stepper motor’s resistance to detect the endstop. This can simplify wiring and reduce potential failure points. Properly configuring the sensitivity for stall detection is key to reliable homing.

The precise configuration of these advanced features will depend on the specific mainboard and firmware you are using (e.g., Marlin, Klipper, RepRapFirmware). Always refer to the manufacturer’s documentation and community forums for detailed guidance on implementing these advanced settings.

Final Conclusion

Embarking on the upgrade to a silent mainboard for your printer is a rewarding endeavor that promises a quieter, smoother, and potentially higher-quality printing experience. By following the steps Artikeld in this guide, you’ll be well-equipped to transform your printer’s acoustic profile and enjoy the benefits of reduced noise and vibration. We encourage you to embrace this enhancement and look forward to a more pleasant and productive printing journey.